Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

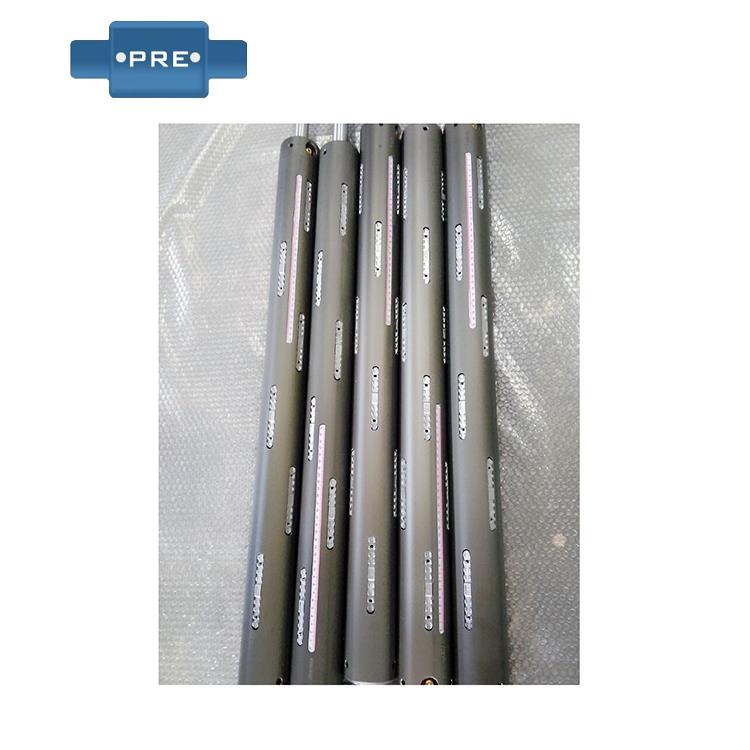

The air shaft is also called the air roller, which is common in the paper coating and printing industries.

A kind of winding and reeling. After the compressed air is inflated, the key strip on the surface of the shaft can be raised (the shaft diameter is increased), and the key strip on the surface after deflation is quickly retracted (recovery of the shaft diameter) for tightening the core.

The surface of the gas-increasing axis is regularly distributed with some collets (protruding), and the collet is retracted when there is no compressed air.

The surface of the shaft is flush, and the paper tube or other tube on the fashion, then the compressed air is introduced into the shaft, which is the top of the chuck, and the solid the paper tube or other tube can be wound around the paper tube with the film, sheet, fiber, etc.On other pipes.

Air shaft characteristics

1, a wide range of applications: Inflatable shaft as an independent design of parts, from 1 inch to 12 inches, the length and length are determined by the customer

Need to be sure, where there are strips, printing, rewinding, coating, lamination, making, making, etc., for the equipment or other related centers.Machinery, can be applied to the furnace shaft of the factory.

2, cost-effective: The design of the shaft is designed for practical work, and can be applied to various types of coils such as thick and wide.

3, long use time, simple maintenance: Although the inflatable shaft is a mechanical accessory, but each part of its own construction. All have fixed specifications and can be used interchangeably to make it easy to maintain. Our factory has strict requirements on the quality of various components of the air shaft. The product quality is absolutely guaranteed.

4. Single fitting: The inflatable shaft is a single part of the winding and unwinding machine. Each part in the structure has a fixed gauge.The size of the grid can be combined and decomposed to make maintenance easy and durable.

5. Professionalism: The factory specializes in the production of air-expansion shafts, and has professional engineers and technicians to design and install the air-expansion shafts.

Field research.

6. Large bearing capacity: The air shaft can be designed according to the actual model, using high-quality steel and increasing the load capacity. For example, bearing weight, More than 1 ton can be made of steel.

7. Short working time: Separating and placing the coil tube can be completed in 2 seconds of inflation and deflation. It is safe and applicable. Applicable to the equipment for winding and unwinding, the air shaft can be applied. The inflation shaft can be up to six Meters or more, up to a few hundred millimeters, are based on customer needs.

8, the key type air expansion shaft expands from a single key bar, the fulcrum spreads to each key bar, balances the force, and can be applied to mechanical collection. A roll with a heavier load.

The integral metal frame excavates a box-type window at the fixed end of the cantilever mandrel operating side to ensure printing

The structural rigidity of the platform, the bearing seat is mounted on the inside of the movable steel block, and the steel block is driven by a high-precision ball screw, the screw.The moving position is on the center line of the plate mandrel, and linear guides are respectively mounted on the upper and lower ends of the box window for fixed movement.

Steel blocks to ensure the stability of the printing platform during high-speed operation. In this design, the mandrel is fixed entirely from

Moving, the movement of the entire screw and the locking of the shaft end eliminate the artificial factors. Mobile steel block passes two straight lines

The guide rail is fixed to the frame, and the thrust of the center impression cylinder against the plate roller is caused by the movement of the screw on the center line of the platen mandrel

And the driving force along the direction of the ball screw acts on the center of the plate mandrel, forming only a small partial pressure, and the force of the force acts only on the center of the plate mandrel and there is no torque on the support frame.

Previous: What Are The Most Practical Methods For Air Shaft Maintenance?

Next: Method For Improving The Adjustment Speed Of The Inflation Shaft