Tension Packaging And Automation

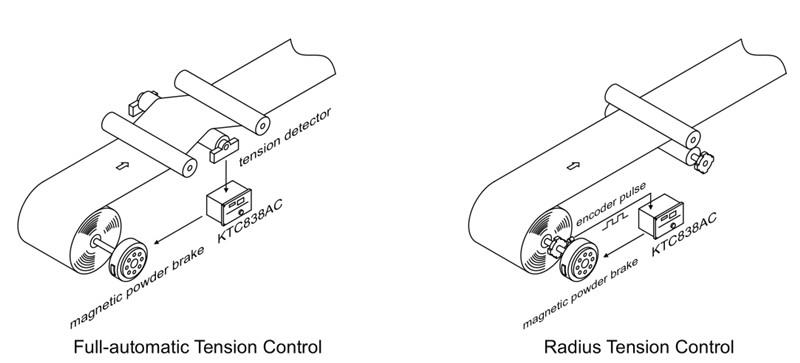

In the winding process of many industrial production materials, due to the change in the diameter of the material and other factors, the tension of the material is constantly changing. In order to keep the tension of the material consistent, it is necessary to adjust the resistance moment or the...

In the winding process of many industrial production materials, due to the change in the diameter of the material and other factors, the tension of the material is constantly changing. In order to keep the tension of the material consistent, it is necessary to adjust the resistance moment or the winding moment of the damping device in time. .

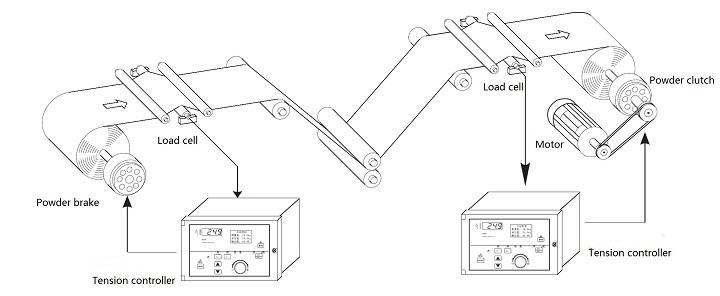

At the unwinding end, the tension of the unwinding is determined by the torque of the magnetic powder brake set at the unwinding end; At the rewinding end, the tension of the unwinding is determined by the transmission torque of the magnetic powder clutch. To increase or decrease the transmission torque. The tension control is divided into manual control and automatic control.The manual tension controller, that is, the steady-current power supply, manually adjusts the exciting current of the magnetic powder brake or magnetic powder clutch in stages according to the change in the diameter of the unwinding or receiving coil, so as to obtain a consistent tension.

Automatic Tension Controller with Taper and Communication Function

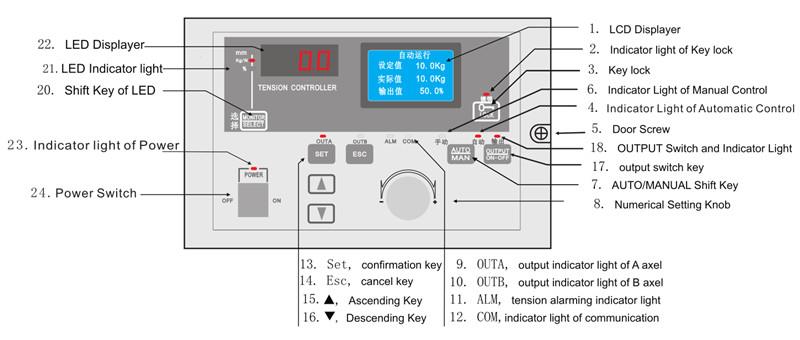

Operating Panel:

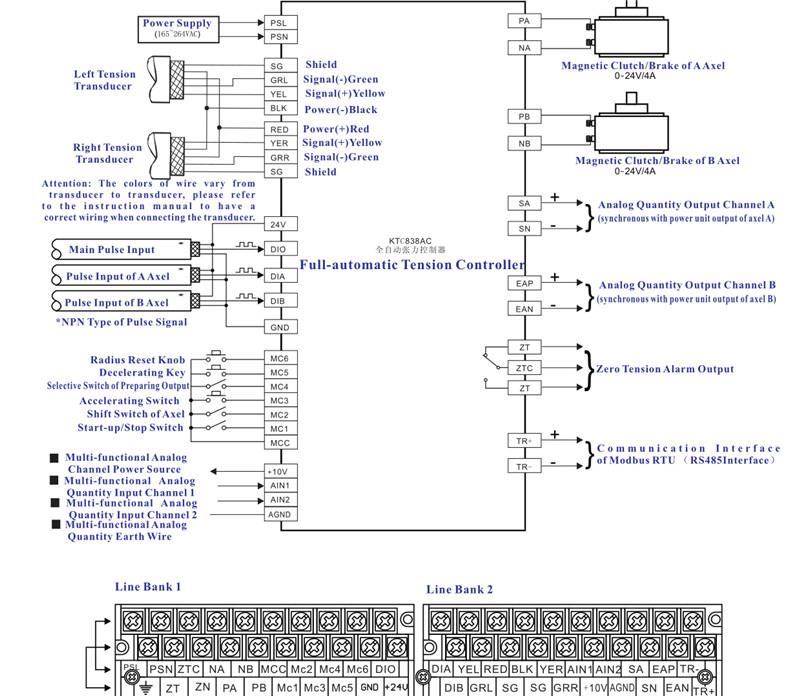

Wiring Diagram:

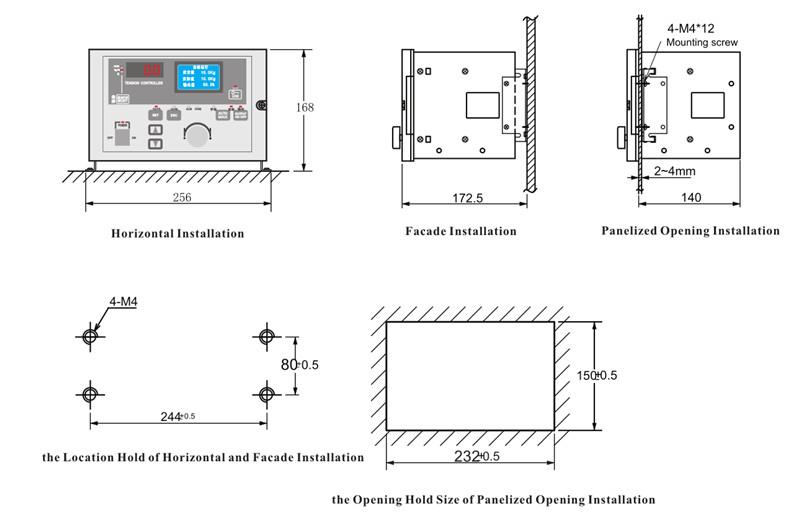

Installation:

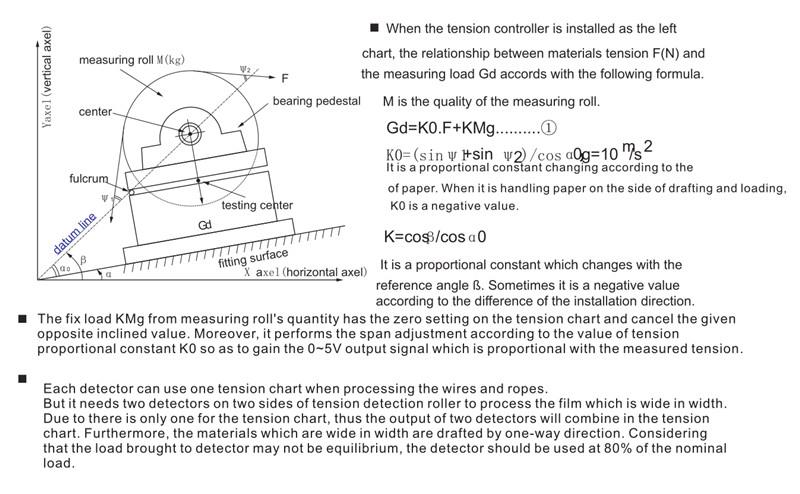

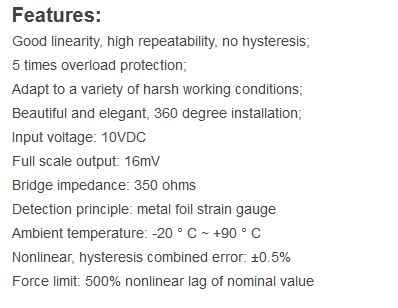

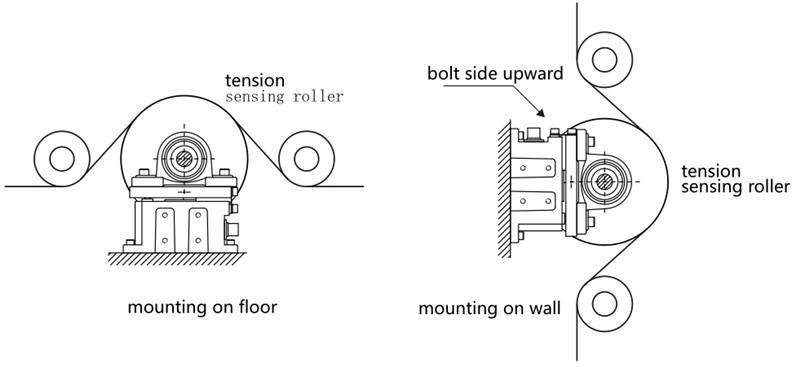

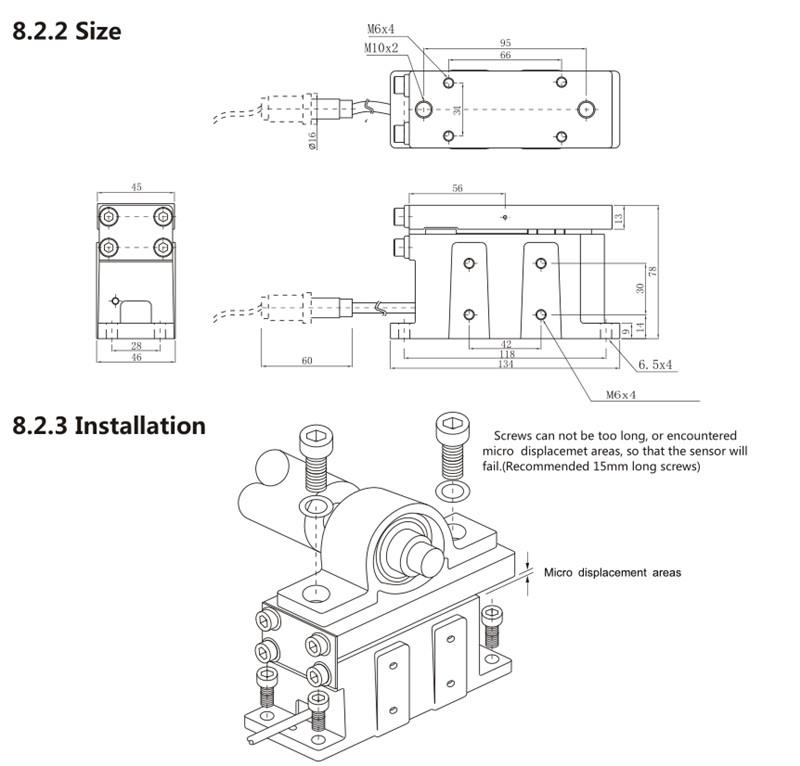

Mounting of Tension Sensors:

Application

Order Details

Item Name | LX Foot Mounted Tnesion sensor KTC-838A Automatic Tension Controller with Taper and Communication |

MOQ(Minimum Order Quantity) | 1Set |

Lead time | 5-7 days after receiving the deposit |

Calculated Packing Size | 20cm*10cm*10cm, 4kg/Pc 20cm*15cm*15cm,2kg/pc |

Package | Carton |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: tension packaging and automation, China, manufacturers, suppliers, factory, quotation, pricelist, buy