Web Tension Control Systems

With the high speed and high performance of all coil equipment such as paper, film, fabric, rubber, foil, copper, etc., it is even more important to maintain the automatic tension control technology of the coil in motion. Generally, when the material is unwound and wound, the coil diameter of...

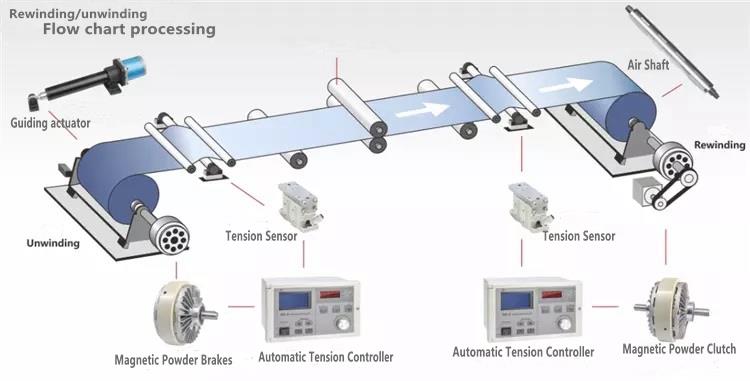

With the high speed and high performance of all coil equipment such as paper, film, fabric, rubber, foil, copper, etc., it is even more important to maintain the automatic tension control technology of the coil in motion.

Generally, when the material is unwound and wound, the coil diameter of the coil will constantly change, and the tension of the coil will change as the winding diameter changes. In this case, if the tension of the web is not controlled, wrinkles, slacks, thickness changes, etc. may occur in the web, and in severe cases, the web may be broken. In addition, in the printing process, the change in tension causes the paper to be stretched or tightened, and registration errors occur immediately. Therefore, tension control of the coil must be performed.

From tension sensors, tension controllers, signal amplifiers to power amplifier boards, we offer the tension detection and control technology needed to control the tension of equipment when handling various webs such as paper, wire, film, and strip.

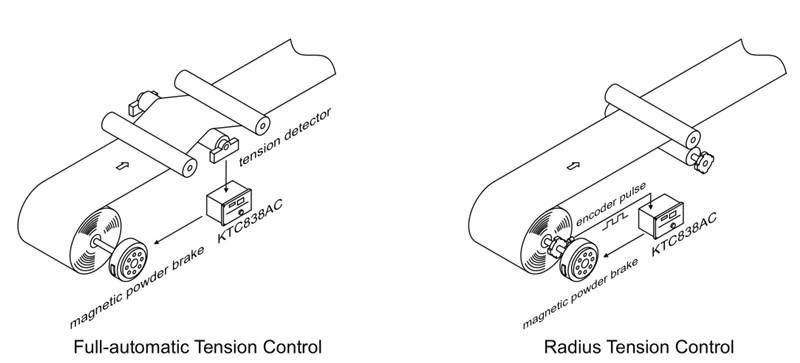

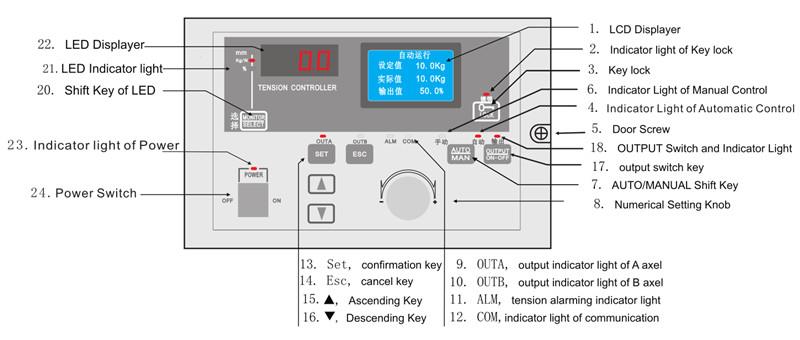

Automatic Tension Controller with Taper and Communication Function

Operating Panel:

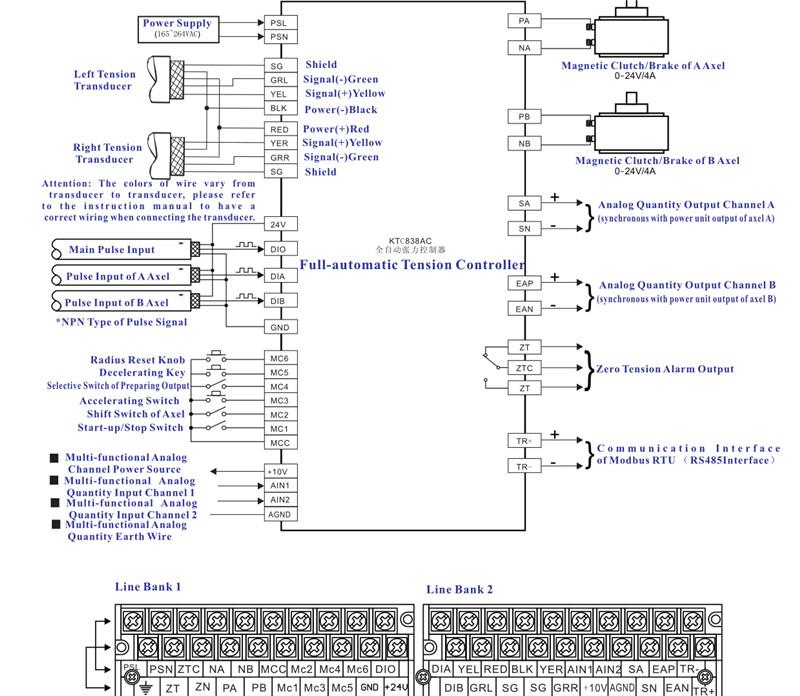

Wiring Diagram:

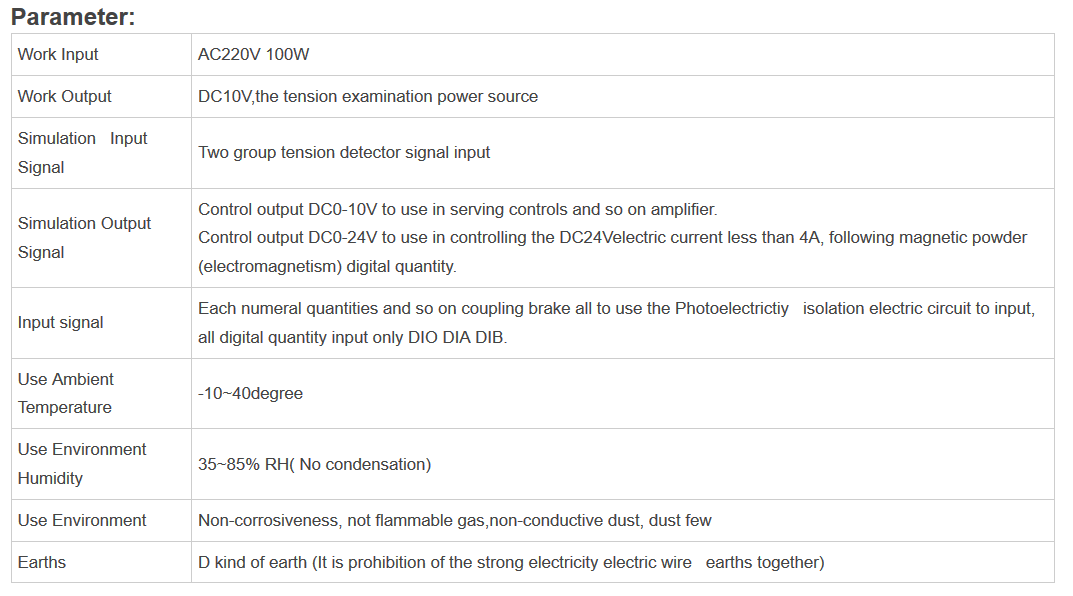

Installation:

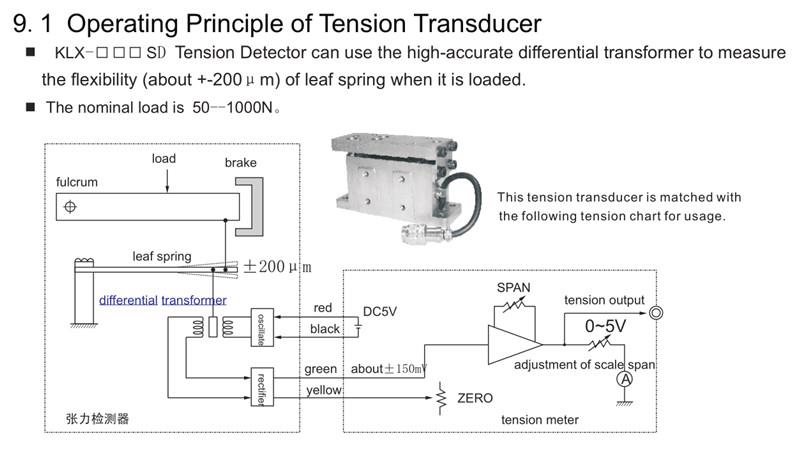

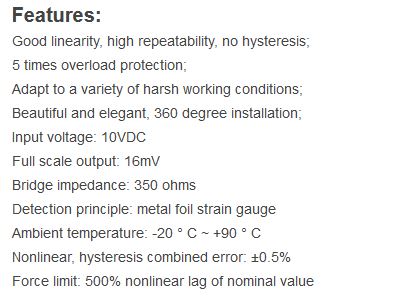

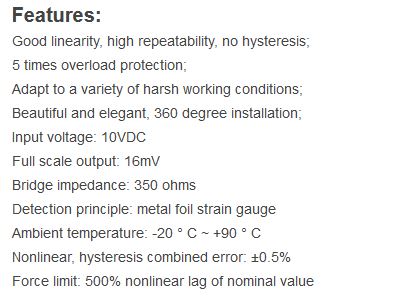

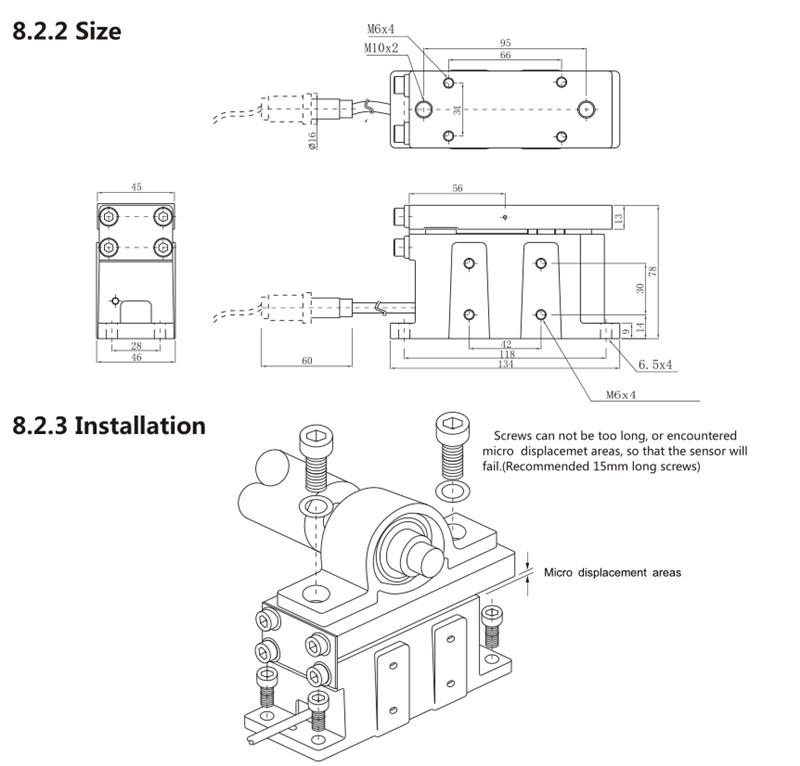

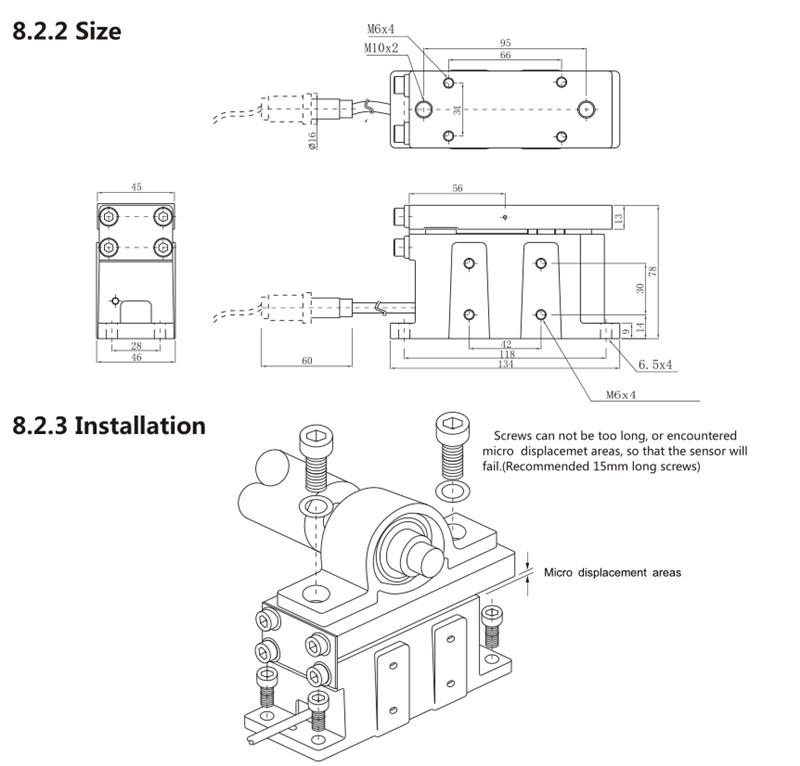

Foot Mounted Tension Sensor LX series

Mounting of Tension Sensors:

The role of the tension control system

In many industries of

industrial production, winding control problems are often encountered.

For example, in the production process of paper, textiles, plastic film,

electric wire, printed matter, magnetic tape, metal strip wire, etc.,

the unwinding and winding tension of the strip or wire is critical to

the quality of the product, and constant tension control is required for

this purpose. That is, the product is subjected to optimum tension

during the winding process and remains unchanged throughout. If the

tension is too large, it will cause tensile deformation of the processed

material; if the tension is too small, the stress between the layer and

the layer of the wound material will be deformed, resulting in

unwinding and affecting the processing quality. In the strip take-up

system, the tension control system occupies an important position and it

is quite complicated.

Order Details

Item Name | LX Foot Mounted Tnesion sensor KTC-838A Automatic Tension Controller with Taper and Communication |

MOQ(Minimum Order Quantity) | 1Set |

Lead time | 5-7 days after receiving the deposit |

Calculated Packing Size | 20cm*10cm*10cm, 4kg/Pc 20cm*15cm*15cm,2kg/pc |

Package | Carton |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: web tension control systems, China, manufacturers, suppliers, factory, quotation, pricelist, buy