Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

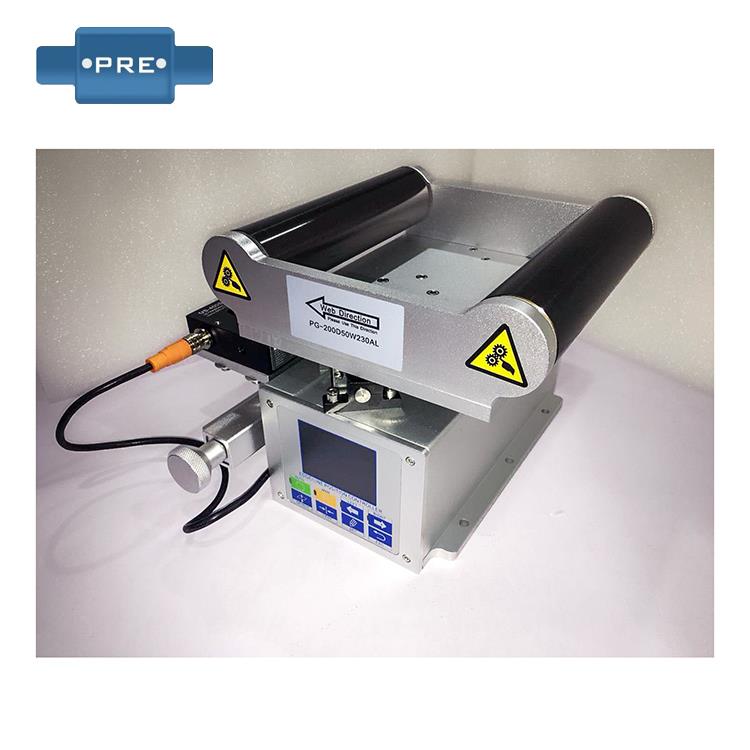

The photoelectric guide device controller is an automatic control system for controlling and guiding the positional deviation of thin materials during high-speed transmission. It has functions of automatic detection, automatic tracking, automatic deviation correction, etc., and can be used for paper, film, dry tape, aluminum foil. Trace lines or edges of strips and other materials are tracked and corrected to ensure that the winding and slitting are neat.

The photoelectric guiding controller adopts the opposite side and the pair of general-purpose photoelectric guiding sensor, supplemented by the imported driving device and the highly precise driver to control the material of the reel and keep its edges and lines at a specified position at any time.

The device is simple in operation, high in precision, good in stability and wide in application. It is suitable for different materials such as black, mirror, white, transparent film, paper, cloth, aluminum foil, etc. It can be used in various printing machines, such as printing machine. , laminating machine, coating machine, slitting machine, embossing machine, inspection machine, paper machine, bag making machine and dyeing machine.

Traditional hydraulic rectification: 1. Due to the leakage in the hydraulic transmission and the compressibility of the liquid, the transmission can not guarantee a strict transmission ratio. The hydraulic rectification is sensitive to the change of the oil temperature, and it is not suitable to work at a higher or lower temperature. Gear pump low-speed self-priming function is poor, usually the gear pump working speed is above 1450rpm. The solvent efficiency after the reduction of the gear pump speed drops sharply, and the internal leakage increases significantly.

Especially in the summer when the ambient temperature is high and the viscosity of the hydraulic oil drops, some gear pumps will not be able to idling and the system will not work effectively. The gear pump is easy to suck in oil in winter, and the shaft end leaks. Because the oil viscosity increases, the oil pump can't suck the oil. The pump is sucked under the vacuum and the air is sucked from the shaft end. The system is invalid. 2. It is not easy to find out the cause when the hydraulic transmission fails. 3. The hydraulic precision is low, and the highest error is 2 mm. 4. High cost of use (large power consumption).

Previous: What Are The Contents Of The Maintenance Of The Photoelectric Guiding Device?

Next: What Are The Contents Of The Daily Maintenance Guide Device?