Industrial Aluminum Foil Rolls

The roller of the aluminum guide roller serves to support the conveyor belt and the weight of the material. The roller must be flexible and reliable. Reducing the friction between the conveyor belt and the idler roller plays a key role in the life of the conveyor belt, which accounts for more...

The roller of the aluminum guide roller serves to support the conveyor belt and the weight of the material. The roller must be flexible and reliable. Reducing the friction between the conveyor belt and the idler roller plays a key role in the life of the conveyor belt, which accounts for more than 25% of the total cost of the conveyor.

The criteria for judging the quality of the rollers are as follows: the amount of radial runout of the idler; the flexibility of the idler; the amount of axial turbulence.

The roller of the aluminum guide roller is an important part of the belt conveyor, and has many types and a large number.

It accounts for 35% of the total cost of a belt conveyor and withstands more than 70% of the resistance, so the quality of the rollers is particularly important.

Although the rollers of the aluminum guide rolls are a small part in the belt conveyor and the structure is not complicated, it is not easy to manufacture a high quality idler.

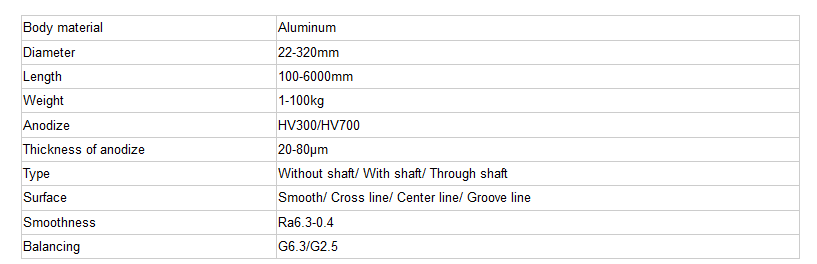

O.D(mm) | I.D(mm) | Wall Thickness | Stiffener |

Ф32 Ф33 Ф40 | Ф24 Ф27 Ф34 | 4:00 3:00 3.00 |

8 |

Ф40.5 Ф42.5 serrated roller Ф43.8 | Ф31 Ф30 Ф34.5 | 5.00 4.50 5.00 | |

Ф47 Ф50.5 Ф51 with groove | Ф40.8 Ф40.5 Ф38 | 3.00 5.00 6.50 | 8

6 |

Ф55 Ф58.5 Ф61 | Ф46.5 Ф51.5 Ф51 | 4.50 3.50 4.90 | 6 8 6 |

Ф70 serrated roller Ф71 Ф71 | Ф46 Ф63.2 Ф61 | 7.20 4.50 3.50 |

8 7 |

Ф74.5 Ф75.5 Ф80 | Ф60 Ф66 Ф73 | 7.20 4.50 3.50 |

8 8 |

Ф81 Ф81 Ф80 | Ф72.5 Ф71 Ф69 | 4.30 5.00 5.50 | 8 8 8 |

Ф90 Ф99 Ф101 | Ф81 Ф90.5 Ф92 | 4.50 4.30 4.50 | 8 8 7 |

Ф101.5 Ф101 Ф101 | Ф91.5 Ф89 Ф86.3 | 4.50 11.00 11.00 | 7 8 8 |

Ф111 Ф115 Ф116 | Ф102 Ф93 Ф94 | 4.50 11.00 11.00 |

7 8 |

Ф120.5 Ф121.5 Ф130.5 | Ф105.5 Ф111.5 Ф118 | 7.50 5.00 6.25 |

9 |

Ф140 Ф145 Ф151.5 | Ф120 Ф123 Ф139.5 | 10.00 11.00 6.20 | 8 7 8 |

Ф151.5 Ф153 Ф162 | Ф131.5 Ф121 Ф148 | 10.00 11.00 7.00 |

9 |

Ф184 Ф203 | Ф168 Ф179 | 8.00 12.00 | |

Ф150.5 Ф151 Ф200 Ф320 | Ф136.5 Ф140 Ф186 Ф296 | 7.00 5.50 7.00 12.00 |

10 |

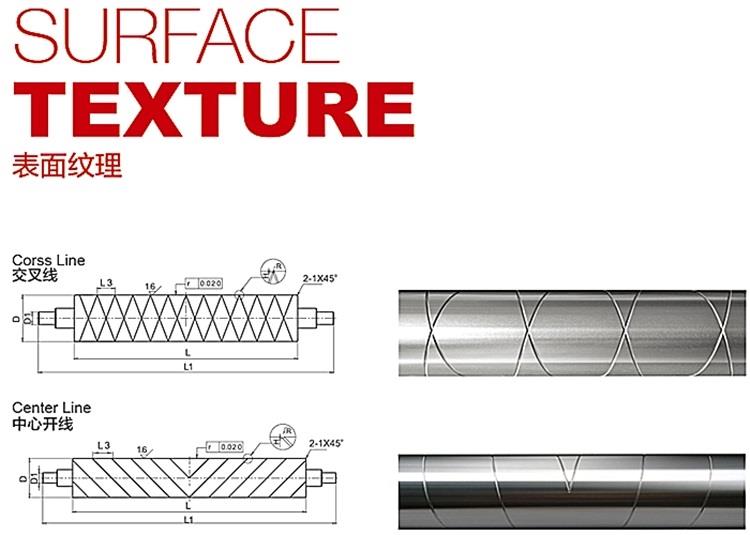

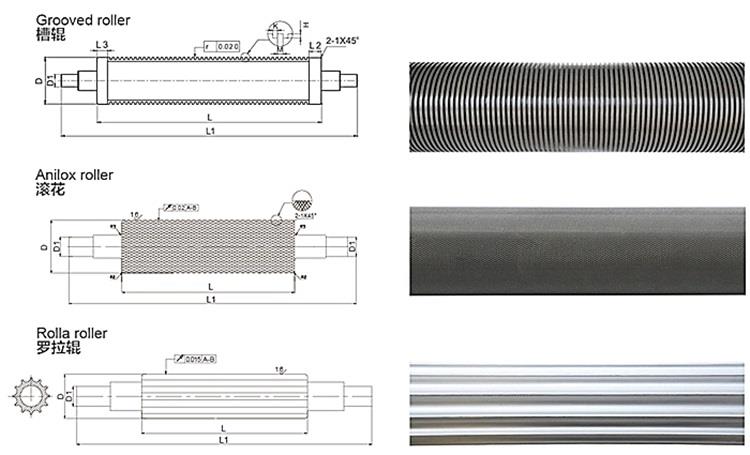

The fineness of the roll products is a measure of quality. Fine roll printing, ink is the key!

In general, the criteria that should be followed for ink: the field, the line, the text, etc. require a large amount of ink, and the number of selected mesh lines is lower; the color network pattern requires a small amount of ink, and the number of selected lines is higher; The requirements of the ink, the number of lines of the anilox roller will be subject to a certain degree of restriction!

On the printing plate, if the dot size is determined, if a lower number of anilox rolls are used, the area of each cell will be larger than the area of some dots on the plate, so that when printing, the dots have no partition wall. Support, the dots will be immersed in the cells.

Not only the surface of the dot is inked, but also the sidewalls are inked, resulting in an increase in dots. For example, a patch of 80% dot size will cause a paste to be printed, which will be printed on the ground and cause edge ghosting.

Application

Order Details

Item Name | Aluminum roller |

MOQ(Minimum Order Quantity) | 1PC |

Lead time | 10-15 days after receiving the deposit |

Calculated Weight | Need to count |

Package | Wooden Box/Pallet packing/according to clients's requirement and demand |

Price Term | EXW,FOB, CIF, etc |

| Payment term | TT,L/C,Western Union |

| Country of Origin | China |

Hot Tags: industrial aluminum foil rolls, China, manufacturers, suppliers, factory, quotation, pricelist, buy