Safety Chuck For Labeling Machine

The characteristics of the safety chuck are mainly as follows: 1. The overall structure of the safety chuck is reasonable, the rigidity is good, and it can withstand large torque and eliminate the looseness during rotation. 2, accurate machining accuracy to ensure accurate positioning, the reel...

The characteristics of the safety chuck are mainly as follows:

1. The overall structure of the safety chuck is reasonable, the rigidity is good, and it can withstand large torque and eliminate the looseness during rotation.

2, accurate machining accuracy to ensure accurate positioning, the reel nozzle uses a special heat treatment process;

3. Provide replaceable VT-type reel holders, which greatly extend the service life of the safety collet;

4, the use of special alloy steel materials with superior performance, superior durability and durability;

5. The bayonet is nickel-plated, and the bayonet is hardened and has high hardness and durability. It can ensure good performance even under heavy load and high speed applications.

6. The reasonable tolerance of the bayonet parts ensures smooth and continuous torque transmission, which greatly enhances the safety of the machine. Simple to install, suitable for continuous sliding or high frequency use, buffer starting, with soft start characteristics.

Safety chuck working principle:

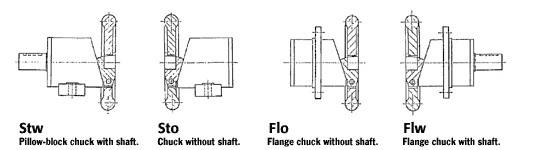

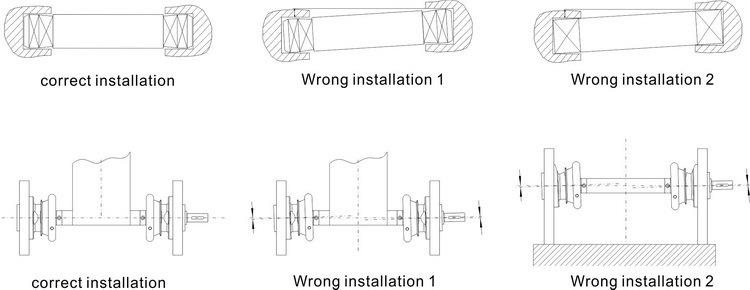

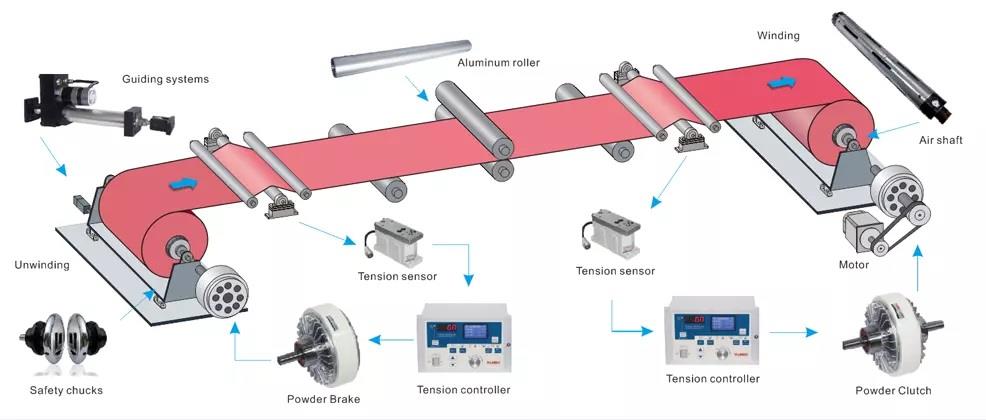

The safety chuck (safety chuck) provides a fast, accurate, simple and safe connection for frequent transmission and disconnection. Can be connected to an inflatable shaft or square steel. There are two installation methods, which are divided into shaft seat type and flange type.

When the shaft seat type safety chuck is installed, the foot is fixed, and the air expansion shaft or the two ends of the square steel are respectively installed into the card slots of the safety chuck. The safety chuck slot can be manually pushed open, automatically homing when rotating, and the safety clip The head end is driven by the motor to drive the chuck to rotate, thereby driving the winding shaft to rotate. The flange type safety chuck does not need to be fixed, and the tail end is directly connected to the motor. Following the rotation of the motor, the operation of the coil discharge shaft is basically the same as that of the shaft seat type.

STOSTW Series Foot Mounted Safety Chuck: STO/STW28,STO/STW35,STO/STW50,STO/STW75

FLOFLW Series Flange Mounted Safety Chuck: FLO/FLW28,FLO/FLW35,FLO/FLW50,FLO/FLW75

Product Features:

1: The chuck is nickel-plated, and the bayonet parts are hardened for durability.

2: With imported heavy-duty bearings, it also ensures good performance in heavy load and high speed applications.

3: Reasonable tolerances of the bayonet components ensure smooth and continuous torque transfer.

Application

Order Details

Item Name | safety chuck for labeling machine |

MOQ(Minimum Order Quantity) | 1Pair |

Lead time | 10 days after receiving the deposit |

Calculated Weight | According to different models |

Package | Wooden Box |

Price Term | EXW,FOB, CIF, etc |

Payment term | TT,L/C,Western Union |

Country of Origin | China |

Hot Tags: safety chuck for labeling machine, China, manufacturers, suppliers, factory, quotation, pricelist, buy