Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Definition of web guide system:

Guiding system refers to the production of coil in the spraying, printing, punching, lamination, slitting or other coil winding process, always to keep the coil side neat and consistent technical operation Its widespread use has brought great benefits to the industry, guiding control makes steel, corrugated, textile, printing, labeling, labeling, papermaking, plastic film, building materials, cables, rubber, tires, non-woven corrugated processing and other industries appear automatic control.

How the guiding system works:

Guiding system principle: infrared light/ultrasonic/laser/visible light is emitted by the guiding sensor B to monitor the operation of the coil and send the signal to controller A. After the controller finds that the coil has a position drift, according to the instructions set by the controller, it controls the oscillation frame C oscillating through drive D to correct the position of the coil. The coil automatic correction system uses a photoelectric sensor to detect the position of the edge of the coil and send the measured position error signal to the controller.

After the control unit judges the processing, the drive motor is controlled to correct the coil where the deviation position occurs to the correct position. FIFE guiding systems offer several different detection methods: edge checking, line following, or centering.

The drive system uses low-speed synchronization, variable frequency speed regulation, stepper and servo motor drive, and the drive stroke is strictly proportional to the coil offset. The system can also be used with different probes to suit the needs of detecting different coils, such as: infrared photoelectricity, analog infrared photoelectric, etc. The microcomputer digital controller provides precise control of the functions of the system.

The more commonly used guiding sensors are ultrasonic and photoelectric guiding sensors, PRE Co.,Limited has been doing these two correction sensors for more than 20 years, and the technology has been very mature.

Installation method of guiding system:

Angle correction of the guiding all-in-one machine, intermediate stroke correction. Installation is very simple, only need to fix the sensor, the corresponding power supply, sensor, external control connector line to the corresponding socket; Then fix the six screws of the base.

After centering the material through the sensor, and then connecting the external 220V power supply, the guiding machine can press the automatic button to work normally;

According to different material roll materials, the corresponding sensor is selected, such as film, copper, aluminum foil, paper and other impermeable materials, ultrasonic sensors can be used; Non-woven fabrics, fabrics and other breathable materials can choose photoelectric sensors.

Split guiding is linear correction, and horizontal installation is generally used.

The role of the guiding system:

It has the functions of automatic detection, automatic tracking, automatic adjustment and other functions to ensure the neatness of material winding, slitting and detection, and can better control the winding, unwinding and adjustment of the errors existing in the entire production process of the entire coil, and better improve the production quality of the coil.

The entire coil production process is better monitored, and the defective rate of the coil produced will be greatly reduced.

Areas of application of guiding systems:

1. Tire and rubber industry: forming machine, carcass cord pre-correction, sidewall pre-correction, laminating drum common template correction, lining layer pre-correction, biaxial stretching machine, film blowing machine, industrial belt laminating machine correction.

2. Packaging printing and paper industry: satellite rotary printing machine correction, concave and convex plate printing machine correction, inspection machine correction, slitting rewinder correction, coating machine correction, etc.

3. Battery industry: lithium battery coating machine, lithium battery slitting machine, lithium battery die rolling machine, battery laminating machine.

Common faults and solutions of guiding machine:

1. The auto-run pusher only goes to one side because the polarity is not set correctly. Workaround: Set the guiding polarity.

2. The auto-run pusher only goes to one side because the correct sensor type has not been selected or the sensor is not calibrated. Workaround: Select the correct sensor model and perform calibration.

3. In the automatic state, the correction direction is opposite, because the correction polarity is opposite, the solution: set the correct correction polarity.

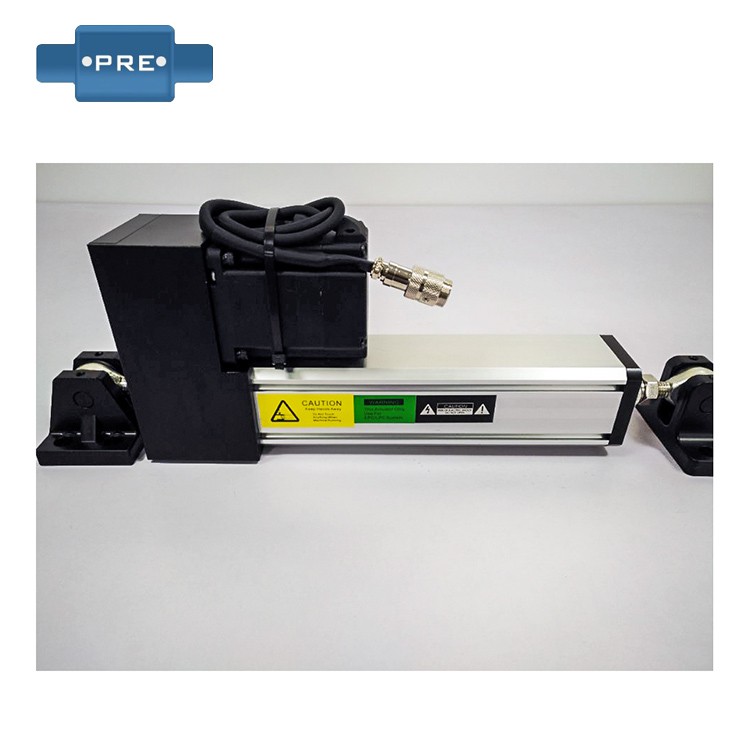

Web Guiding All-in-one Machine

Web Guide Sensor

Edge Guide Controller

Actuator

Previous: No Information