Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

In the production process of biaxially stretched plastic film, the web guiding system greatly reduces the probability of cross-pulling, wrinkling, film rupture, corrugation and other problems, realizing high-speed and high-efficiency production of thin films, and integrating domestic and international web guide control systems. we briefly introduce the guiding systems from several aspects such as working principle and control methods.

Working Principle

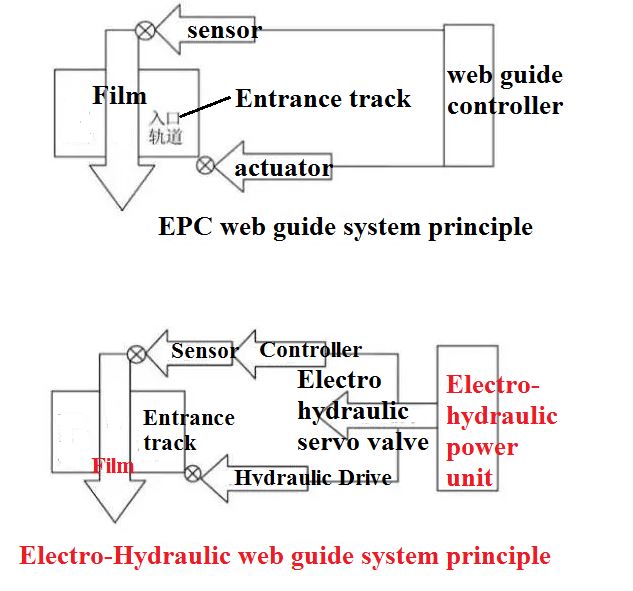

The EPC web guiding device is installed at the TDO inlet of the film production line to accurately track the position of the film edge. The working principle can be simplified to a closed loop control loop: the starting point for automatic correcting is to pull the current position of the inlet film by one or more sensors. Scan the current position of the film and transmit it to the controller; the controller compares the measured actual position with the set position. If there is a deviation between the two, the controller will transmit a guiding signal to the driver; the drive is fast Drive the track of the TDO inlet so that it tracks the edge of the film in time. In this cycle, the web guiding system always drives the track to reciprocate, so that material removal and offset phenomenon do not occur.

Structure and Classification

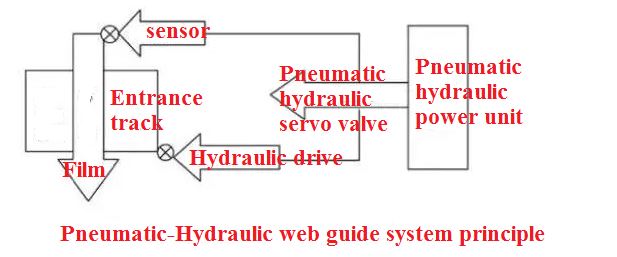

According to the power equipment of the EPC web guiding system, it can be generally divided into four types: electromechanical, electrohydraulic, pneumatic and magnetic.

The structure of the electromechanical EPC web guide system is shown in the following figure. It consists of three main components: web guide sensor,web guide controller, and electromechanical actuator/driver.

The structural principle of the electro-hydraulic EPC web guide system is shown in the following figure. It consists of five major components: guiding sensor, guiding controller, electro-hydraulic servo valve, electro-hydraulic power unit, and hydraulic actuator/drive.

The magnetic EPC web guiding system is still in the experimental stage, mainly applied by Bruckner, Germany. There is still no relevant information in China. At present, the two types of biaxially stretched plastic film production lines at home and abroad are mainly used.

The three control systems are similar in structure, including sensors, which can be divided into infrared sensors, reflective infrared sensors, ultrasonic sensors, digital sensors, pneumatic sensors, laser sensors, and camera sensors, among which electromechanical and electrohydraulic. It is mainly used in infrared sensors and ultrasonic sensors. Electromechanical and electrohydraulic web guiding systems also have a controller that is simple to operate and powerful. It has a high dynamic response level and detection accuracy when the film is produced at high speed. It can be monitored in real time and remotely. control.

The electromechanical EPC drive mainly relies on the electric push rod. It has simple equipment, small recoil and maintenance-free. It is directly driven by the controller, so it has the most sensitive dynamic response performance, and its typical accuracy error is less than 0.002s. However, such push rods are mainly driven by belts, screw rods or gears. In the case of assembly errors, long-term wear, etc., their service life is not as good as that of pneumatic hydraulic and electro-hydraulic EPC systems. Pneumatic hydraulic EPC guiding system mainly relies on pneumatic hydraulic servo valve to control cylinder drive. The biggest feature is stable operation. Unlike the electromechanical EPC drive, it uses a pneumatic sensor to track the position of the film and directly feeds the detected air pressure signal to the pneumatic hydraulic servo valve. Because the film has a distance from the gas source port, the dynamic response accuracy is not as good as the electromechanical control method. Furthermore, the hydraulic oil used will block the oil passage in the case of impurity contamination, etc., so the maintenance frequency is high. The electro-hydraulic EPC guiding system combines the advantages of these two control methods, using infrared or ultrasonic sensors to achieve accurate detection, and feedback signals to the electro-hydraulic servo valves through the controller to achieve precise control of the controller. It not only avoids the shortcomings of the dynamic response level of the pneumatic sensor, but also retains the advantages of stable operation of the pneumatic hydraulic type, but also has the problem of oil path impurities.

Operating mode

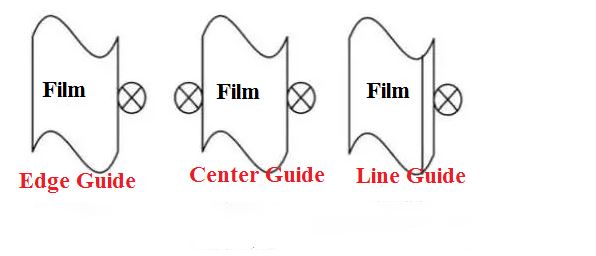

The choice of the web guiding mode depends on the customer's process requirements. The main guiding modes are as follows:

1. Film edge guiding: Use a sensor to guide the deviation according to the left or right edge of the film;

2. Film center guiding: Two sensors are used to align the offset according to the center line of the material, and can be divided into fixed centering guiding and moving centering correction;

3. Film line guiding: Use a sensor to correct the deviation based on a continuous or discontinuous line contrast.

The edge guiding can only detect the edge change of one side of the film. When the width of the film from the longitudinal stretching machine changes, the distance between the diaphragm at the entrance of the TDO and the chain clips on both sides cannot be ensured, so it is difficult to achieve the ideal. The film under the state. Alignment of the line requires a contrast line to accurately track the detection, which is time consuming and labor intensive compared to the other two methods. The centering line can always maintain the stability of the film width at the entrance of the TDO. The clips on both sides of the chain clamp are accurate, and the clips are synchronized at the same time. The clips are even and the clamping force is moderate. The diaphragm entering the inlet keeps the flat conveying, which is conducive to smoothing. The grain stretching orientation of the subsequent stretching zone. Therefore, most biaxially oriented plastic film production lines use a centering line guiding mode.

Control Method

The control mode of the EPC guiding system is automatic control and manual control, which are generally both. The EPC guiding control of all film production lines adopts automatic control mode during production. The manual control mode is mainly used for static test system operation status in order to find problems in time.

Taking the pneumatic hydraulic EPC web guiding system as an example, the control flow is as follows: The power system has a dual-axis motor that is always in working state, connected with a hydraulic pump and a gas pump to ensure the pressure and oil pressure of the control circuit. In the automatic control mode, when the edge of the film just blocks half of the air supply port of the pneumatic sensor, the air pressure respectively loaded on the pneumatic hydraulic servo valve by the pneumatic sensor and the automatic control valve is kept in equilibrium, the cylinder is at rest, and both sides of the inlet are The guide rails also remain relatively stationary, and the chain is normally sandwiched. When the film moves, blocking more than half of the air source of the pneumatic sensor will make the air pressure of the pneumatic sensor loaded on the pneumatic hydraulic servo valve become larger, the pressure is unbalanced, the automatic control valve pressure pushes the gas-liquid servo valve to work, and the control hydraulic oil The running direction is changed, so that the track moves to the outside, and the hydraulic oil is prevented from flowing back through the circuit lock valve to ensure the stability in the orbital motion, thereby ensuring the distance between the pinch points on both sides and the film edge to achieve the ideal film. When the other side of the pneumatic sensor does not detect the film, the gas-liquid servo valve will move in the opposite direction, eventually moving the track to the inside. This is repeated to achieve real-time tracking of the position of the membranous membrane, ensuring smooth clamping of the TDO inlet.

In the manual control mode, the gas pressure servo valve is actuated directly by manually controlling the air pressure direction of the valve to test the operation of the system.

Sum up

The application of guiding control system in the biaxially stretched plastic film production line is undoubtedly successful. It greatly reduces the probability of occurrence of problems such as cross-clip, wrinkle, film rupture and ripple jitter, and realizes high-speed and high-efficiency production of film. Nowadays, the web guiding control systems produced on the market are varied and include various structural types and modes. Customers should combine the advantages and disadvantages of the various systems listed in this paper according to different film processes, materials and production speeds, and choose a suitable correction control system to better promote the production of biaxially stretched plastic film.