Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Printed packaging refers to the printing of decorative patterns, patterns or text on the packaging to make the product more attractive or more illustrative.

The label industry mainly focuses on self-adhesive labels, and its application fields are very extensive, involving industries such as daily chemicals, electronics, medicine, food, supermarkets, logistics, and product anti-counterfeiting.

It can be seen from the development trend of labels in recent years that flexographic printing, narrow-width rotary printing and digital printing have become the new highlights of label printing, and also the development trend of label printing.

As a leader in the coil & web industry, PRE CONVERTING has been providing complete solutions for the printing and packaging industry.

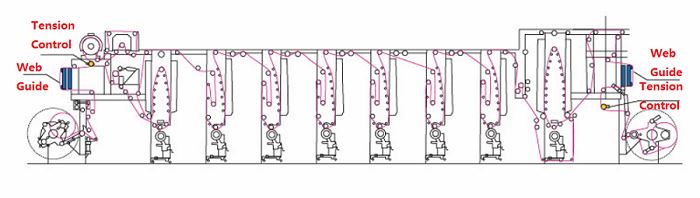

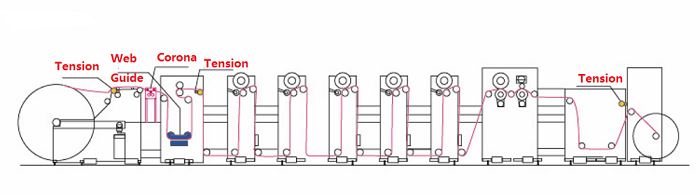

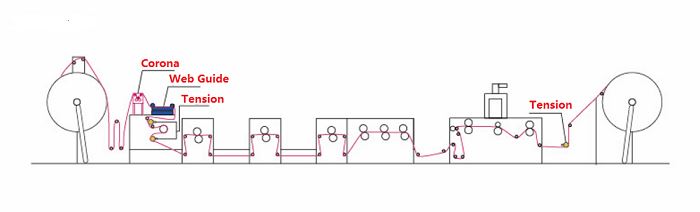

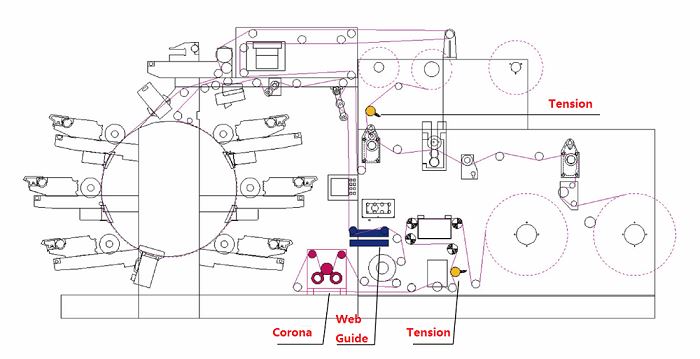

The following is a schematic diagram of the application of web guide, tension control in the printing and packaging industry:

(a):Gravure Printing Machine

![]()

(b).Label Printing Machine:

(c).Form Printing Machine:

(d).Satellite Rotary Press:

PRE CONVERTING's products, such as web guiding system, tension control system, etc., are widely used in the above printing and packaging equipment due to their stable quality, high precision and easy operation.

1:The web guide control system:

PRE CONVERTING is committed to the design and development of a truly innovative and practical coil rectification control system for the continuous and precise control of various production processes in the production process of printing and packaging materials. Types of strip material limit waste and downtime to a minimum, ensuring that the machine is functioning properly, reducing production costs, improving product quality and productivity.

PRE CONVERTING is a crystallization of advanced technology that provides stable, accurate corrective performance through a simple, easy-to-operate interface. The controller's advanced setup features automatically determine and set the deskew polarity, deskew point and system gain. Microcomputer digital and touch controllers provide precise control of the system's functions. The system offers several different detection methods: edge guide, line guide or center/alignment guide. Different types of sensors such as ultrasonic, infrared and photoelectric can be selected depending on the materials tested. The drive system is driven by a servo motor, and the drive stroke is strictly proportional to the offset of the coil, ensuring faster and more accurate response of the entire system.

2:The tension control system

As printing speed and precision continue to increase, the requirements for tension control systems continue to increase. The closed-loop automatic tension control is to directly measure the actual tension value of the coil by the tension sensor, and then convert the tension data into a tension signal and feed it back to the tension controller or PLC, and compare this signal with the preset tension value of the controller,to calculate the control signal output, and the execution unit is automatically controlled so that the actual tension value is consistent with the preset tension value to achieve the purpose of tension stabilization.

PRE CONVERTING tension control system has a wide range of applications in the printing and packaging industry. With the improvement of automation, the precision of the tension control of the coil is getting higher and higher. PRE realizes the real constant tension control with precise detection and control system. In the field of tension control, PRE has rich experience in tension control, and has a full range of tension control products. Its excellent tension controller, tension detector, tension display, tension signal amplifier, etc. provide customers with perfect solutions. .

PRE tension control system solves many problems of tension control on the coating machine, printing machine, slitting machine, compound machine and other models. These troubles are mainly in material unwinding, feeding traction and discharging. During the traction and winding process, the four tensions refer to the four tensions of unwinding tension, feed traction tension, discharge tension, and winding tension. All four tensions are output to the variable frequency motor, magnetic powder brake/clutch, servo motor, etc. through the PRE tension control system to achieve automatic tension control. The web/coil can achieve stable tension control in both low speed and high speed processes. In addition, the PRE tension control system can also perform high-speed non-stop roll change and new roll pre-drive functions to better meet customer needs.

Previous: Application of Web Guiding System in Lithium and New Energy Industry

Next: No Information