Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Lithium batteries have been widely used in people's lives, such as portable electrical products, new energy vehicles and energy storage. Especially in the field of portable electronic products, such as notebook computers, mobile phones, digital cameras and digital video cameras, which are widely used, among which laptops and mobile phones are the most used. With the implementation of new energy vehicle policies in various countries, lithium batteries in the field of new energy vehicles are expected to usher in explosive growth.

PRE is currently in the lithium battery industry, providing a complete system solution including web guide control system, tension control system, corona system and visual defect detection system for the production lines of pole pieces and diaphragms. It is widely used in coating machines and cents, cutting machine, die cutting machine, winder, tenter and other equipment.

1.PRE Web Guide System

In the lithium-ion coating and slitting industry, in the continuous rolling production line of the battery pole piece, the pole piece appears to be deviated due to mechanical errors in the unit, deviation of the guide rod, vibration and fluctuation of the pole piece tension. It makes the pole piece easy to cause damage during the rolling process, seriously affecting the product quality and economic benefits, and the tower type roll phenomenon often occurs in the winding process.

The optical slitting machine, because the material is expensive and thin, a slight offset material will be scrapped and scrapped, which will also result in waste of materials, resulting in a decline in customer economic efficiency.

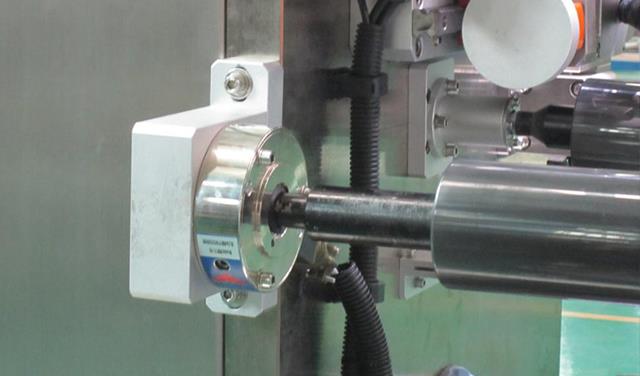

The PRE CONVERTING aligner guide system effectively overcomes these problems and is at the leading level in the industry. PRE CONVERTING detects the offset of the material through the sensor. After the controller compares the operation, it sends the action command to the driver in a very short time, thus ensuring that the material can run according to the specified line in the mechanical work, and the correction accuracy can reach 0.1mm. , fully meet the customer's accuracy requirements.

2.PRE Tension Control System

In the production process of lithium plating and slitting, the magnetic powder brake is generally used for unwinding, and the magnetic powder clutch or the differential shaft is used for winding. The torque of the magnetic powder changes with the current. Currently, all controllers basically use the voltage output mode to control the magnetic powder. The voltage output type causes the torque transfer of the magnetic powder to be unstable, the linearity is deteriorated, and the tension fluctuation is large. The tension controller of PRE uses current output to make the torque transmission of magnetic powder more stable and reliable, and the tension fluctuation is greatly reduced. The web is more evenly coated during the coating process and the slitting is smoother. On the market, tension detectors are currently basically using differential transformers to detect tension. The differential transformer has a fatal weakness that is zero drift and tension control is unstable. PRE tension sensor adopts metal foil strain gauge wheatstone full bridge design, strong anti-interference ability, zero drift, wide detection range, fast response and good linearity.

PRE CONVERTING tension control system and automatic control of tension can be realized directly on variable frequency motor and servo motor. The coil can achieve stable tension control in both low speed and high speed processes. In addition, the PRE tension control system can also perform functions such as high-speed non-stop roll change and new roll pre-drive. Users can not only perform various operations and settings through the operation panel of the controller, but also connect it to the PLC or computer to make operation. It is more convenient and faster, and better meets the needs of customers.

Previous: How Does Web Guide System Apply On Hygiene Products Industry

Next: Application of Web Guide System in Printing and Label Industry