Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

The corrugated box industry is developing rapidly. With the maturity of the market and the continuous upgrading of technology, corrugated paper producers need to further improve the equipment level and improve the quantity and quality of products in order to survive and develop.

PRE offers a complete range of solutions for the corrugated paper industry including bridge guide systems, flyover tension, slitter rectification, corrugated dust removal to help industry customers meet ever-increasing equipment requirements.

Bridge web aligner system and overpass tension control system:

In the production of traditional corrugated board production lines, paper rupture and paper breakage caused by the use of mechanical baffle rectification occur frequently, resulting in loss of materials and time. Furthermore, when the material web changes during production, the material the misalignment will cause the dried pulp line on the hot plate of the hot plate to remain, and the operator needs to clean the residual paste to continue the production, which reduces the efficiency of the corrugated board production line.

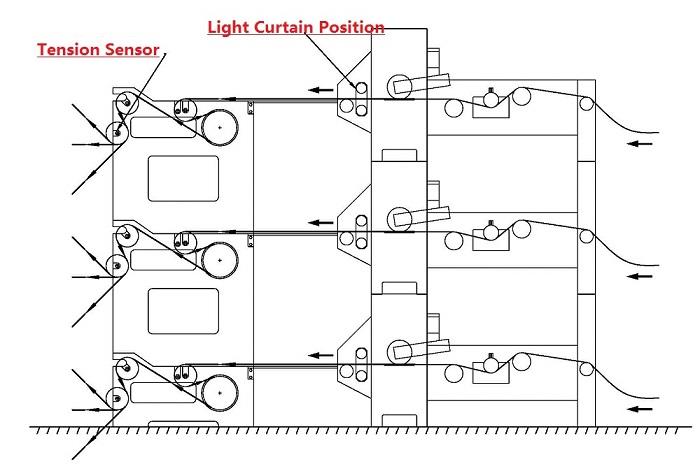

The PRE-Bridge guiding system adopts a wide-range infrared detector, which can flexibly select the centering or opposite side guiding mode, and can also continuously detect when the paper width is changed without manual intervention, suitable for 3, 5, 7-layer corrugated board. Processing and production. In addition, it can detect the width of each layer of cardboard, perform a layered display or output a width signal. PRE's wide infrared detector housing is highly sealed, dustproof and waterproof. It can be used in harsh production environments with accurate detection and easy to use. Without stable tension, it is impossible to produce corrugated paper of stable quality. The PRE tension detector measures the paper tension at the exit of the bridge, and continuously compares the actual measured value with the preset value. The result is output by the tension controller according to the comparison result. Control signals that drive the pneumatic brakes and change the torque of the anti-reel to achieve the desired stable paper tension.

Slitting machine web guide:

The slitting and creasing machine is an important part of the corrugated board production line, which can greatly reduce the waste of cardboard. PRE slitting machine guide system adopts high-precision, wide-width CCD detection probe, with large thrust electric drive, precisely aligns the edge of the paper or printed line, corrects the centering or opposite sides, ensures accurate and stable cutting, and reduces corrugated paper. The number of waste edges.

Corrugated paper dust removal:

In order to reduce the downtime of the printing process in the downstream printing process, corrugated board production line manufacturers need to configure an effective dust removal device to remove dust on the surface of the corrugated board.

In line with the development needs of the industry, PRE is leading the launch of the corrugated paper dust removal system. The system uses a patented three-chamber structure to generate a strong air flow, which can effectively remove the dust on the corrugated paper surface and greatly reduce the downtime of downstream printing manufacturers.