Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

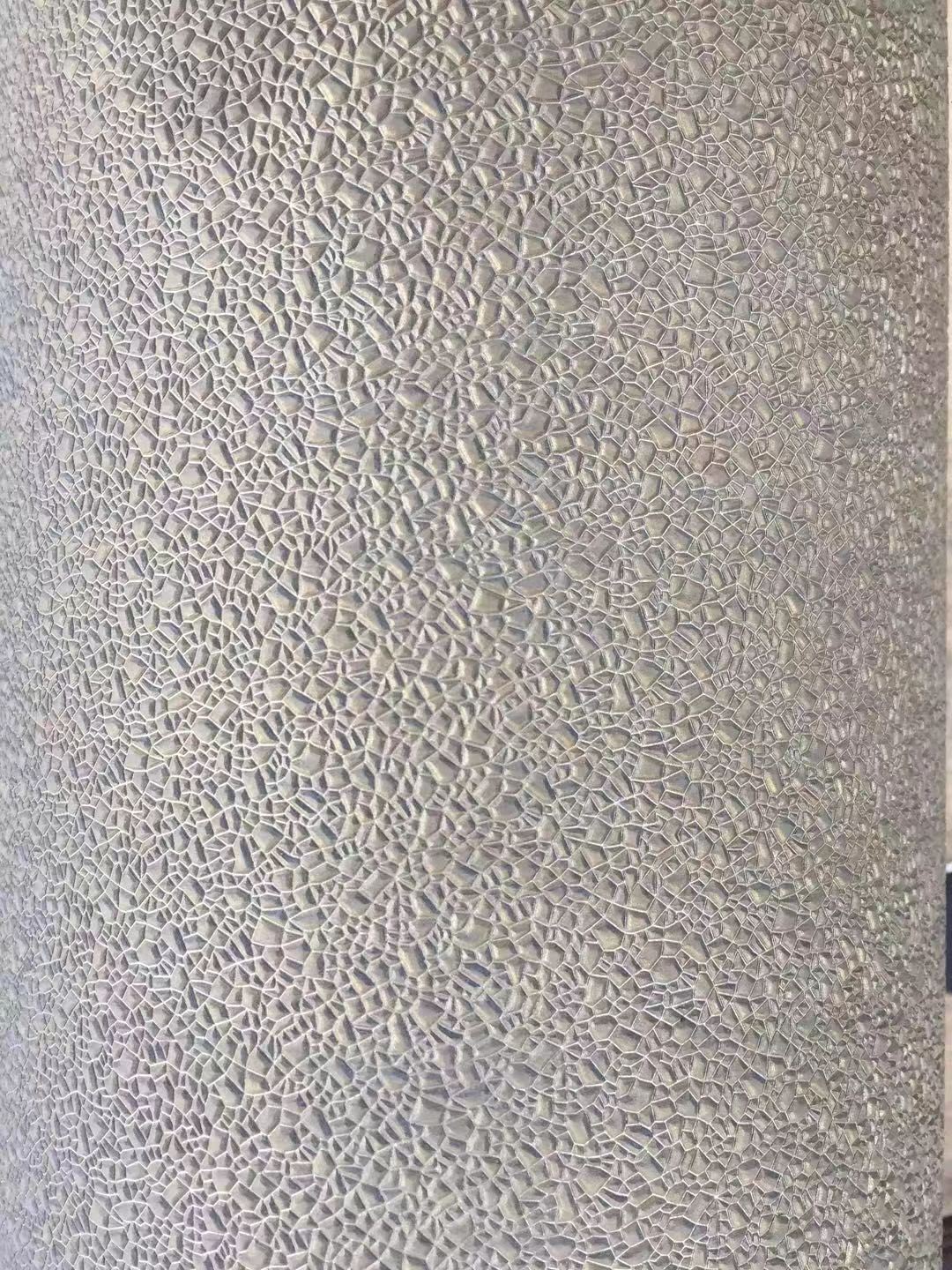

Embossing rollers are suitable for the embossing of concave and convex patterns on plastic sheets, films, aluminium foils, leathers, rigid boards, wallpapers, floor tiles, glasses, papers, etc., which can improve the aesthetics of product surfaces, strengthen the anti-counterfeiting, protect the trademarks and other effects. We can also develop different pattern embossing rollers according to customers' requirements.

Scope of application:

In order to ensure the quality of embossing machine steel roller, manufacturing embossing machine steel rod should pay attention to the following ten processes:

1. put the combination of welded complete inner set into the roller body, the combination of welded inner end plate and the roller body of the mating junction.

2. material: roll body with seamless steel pipe, shaft with 45 round steel, end plate with Q235 steel plate, according to the size of the drawings to leave 8mm machining allowance cut materials.

3. Welding combination of roller body reinforcement, both ends of the shaft and other parts, pay attention to the correction of both ends of the shaft and the coaxiality of the inner casing, and only weld the shaft on the inner end of the plate.

4. turning process: turning processing roller body, end plate and shaft and other parts of the parts with the combination of surface, according to H9/f9 with precision processing.

5. Turn the end face of the steel roller shaft and drill the standard centre hole.

6. Install the outer end plate on both ends of the shaft and weld the outer end plate to the junction of the shaft and roller body.

7. Anneal welded roll blanks to remove internal stresses.

8. Calibrate the static balance of steel rollers.

9. Turning: Rough and finish turning of all parts of the steel roll body to the dimensions required by the drawings. The roughness of the working surface of the roller body should be not more than 1.6μm; the tolerance of radial runout of the working surface of the roller to the two ends of the shaft support surface (rolling bearing mounting part) is 0.025mm; the roundness of the working surface of the roller body is 0.036mm; the bearing with the circle is processed according to the precision of k6. Then set up the centre frame, turn the end face, drill holes to size.

10. According to the pattern requirements of patterned steel rollers processing pattern. Then plating hard chrome layer, thickness of 0.03~0.05mm.

Next: No Information