Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

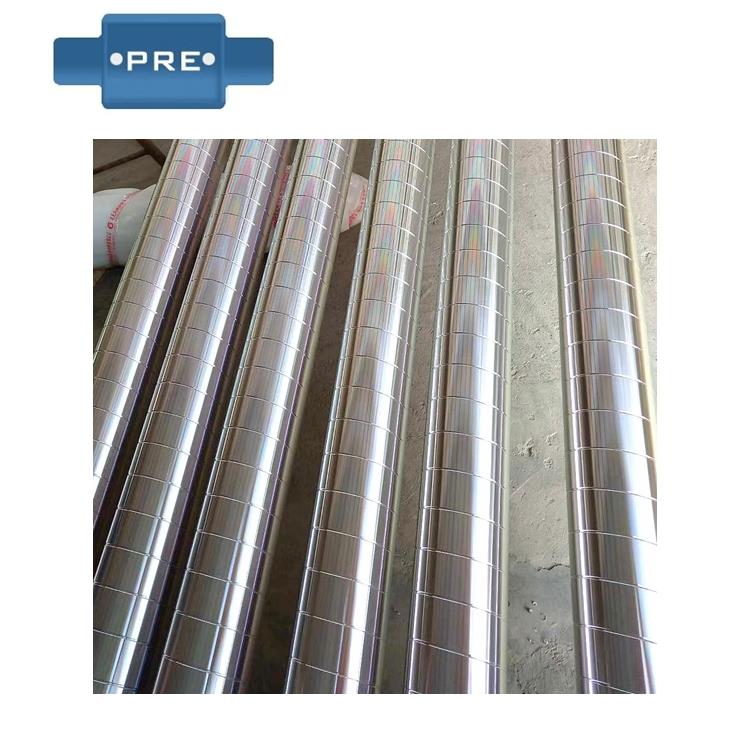

The composite roller, the guide roller and the roller have an important role in the printing of the composite film. The unevenness of the roller causes the spots of the glue, and the imbalance of the guide roller and the composite roller causes the composite film to wrinkle.

1. The peeling strength of the composite film is not enough

Divided into the following cases:

The glue is not completely cured, and it is sticky on the glue surface when peeling off. the reason:

1) The ratio of the binder is wrong, and the ratio of the curing agent is insufficient to cause incomplete curing. When formulating the adhesive, it should be prepared according to the proportioning parameters specified by the adhesive manufacturer;

2) The purity of the solvent is insufficient. The solvent contains water or alcohol exceeding the standard, and the water or alcohol reacts with the curing agent in the glue. The reduced ratio of the curing agent causes the glue to be incompletely cured. The solvent used for the dry recovery is ethyl ester, so the ethyl ester should be sampled in each batch when it enters the factory. If it is found to be insufficient in purity, it cannot be used;

3) The high residual solvent of the ink in the printed film causes insufficient curing of the glue. Some of the residual solvent of the ink (especially PET ink) reacts with the curing agent in the glue, so that the curing agent is consumed and the glue is not cured enough. Countermeasures: 1 After the film is printed, it is best not to recombine immediately. If time permits, it can be placed for 1-2 days before compounding. 2 After printing the film, the residual solvent is detected. If the residual solvent is high, the curing can be appropriately increased during compounding. The ratio of the agent; 3 the choice of fast curing glue.

4) The composite film has a low curing temperature and insufficient curing time, and the crosslinking is insufficient and the curing is incomplete. Countermeasure: Increase the curing temperature or use a fast curing glue.

2, the apparent problem of composite film

1) Small dots. Generally, it is less likely to appear immediately after lamination, except for impurities such as dross. This phenomenon may occur in aluminized film for a period of time after lamination, because the ink is corroded by aluminum, when the ink exhibits a certain acidity or alkalinity, and the amount of sizing is small, and a layer of connection cannot be formed. This can happen.

2) Small gray dots. There are two possibilities for the appearance of small gray dots. One is that the unevenness of the roller causes the spots of the glue, and the other is that the ink caused by the unevenness of the ink has no compact spots. Both possibilities are related to the process and can be solved by adjusting the process to increase the thickness of the glue.

3) Small white spots. In general, the surface of the ink is likely to appear in the case of discoloration. Most appear in the composite of aluminized film. There are two reasons for this: First, the hiding power of the ink is not strong or the cover is not uniform, especially the white ink, so that the color of the aluminum penetrates out, no small white spots are formed at the place where the aluminum color penetrates; the second is the process reason, the temperature of the drying tunnel (especially the first drying tunnel) is too high or the amount of glue is too thick, which causes the surface of the rubber layer to condense in the first drying tunnel. When the ethyl ester is punched out in the second and third drying tunnels, the glue is squeezed to show the true color of the ink. . The solution is to increase the ink hiding power or the temperature of the first, second and third drying tunnels to adjust the temperature and gradually increase the temperature. Avoid the first level of temperature is too high.

4) Small crystal points. Small crystal dots occur on the transparent film, and there are two kinds of bumps. The causes are different: most of the small crystal points protruding are glued, or it may be because the machine is not cleaned. The method of eliminating small crystal points is to match the glue according to the correct glue method. After the machine is used, it must be cleaned; the small crystal points that are recessed, carefully observed with a magnifying glass, will find small bubbles, which are mainly It is caused by too much water.

5) Small spots. Mainly due to the film activation process uneven film, the same defects occur in the printing process, of course, may also be caused by too long activation time.

6) Wave pattern. The wavy pattern is easy to occur on the white film, mainly because the molecular weight of the glue is not neat, after the hot drying tunnel, after the hot roller, the elastic polymer chain shrinks, the intramolecular shrinkage of different molecular weights is inconsistent, and the internal shrinkage is not Evenly causes wavy lines. In this case, the reason for the glue should be considered.

7) The effect of the film on the surface quality. Due to various factors such as the smoothness of the surface of the film and the degree of uniformity, a similar phenomenon of the above six phenomena may be caused. To distinguish between the reason of the film or the above six conditions, the film without the lamination can be carefully observed with a magnifying glass. Since the transparent glue is between the two films, a composite film is formed together with the two films, and the magnifying glass is used. Spots on small films, waves, etc. are magnified, and many cases require careful observation to identify problems.

3. Tunneling phenomenon of composite membrane.

After the compounding, due to the shrinkage of the film, the edge portion or the central portion is like a wavy delamination, which is called a composite film tunneling phenomenon. The reasons for this phenomenon are mainly the following:

1) In the composite process, the poor control of the tension causes the composite substrate to shrink after compounding and the shrinkage ratio is quite different, which breaks the bonding of the glue layer of the composite film, and the tunneling phenomenon is solved according to different composite substrates. The tensile properties set the appropriate tension.

2) The film is wrinkled and the thickness is uneven. In order to prevent the composite film from wrinkling during the compounding, the tension is increased and the composite film is tunneled. The solution is to check the state of the film during unwinding during compounding, such as the phenomenon of film wrinkling, fluttering, etc.

3) The molecular weight of the binder is small, resulting in a low initial adhesion of the composite membrane, thereby causing a tunneling phenomenon of the composite membrane. The solution is to use high molecular weight, high cohesion, fast curing adhesives.

4) Due to the excessive coating amount of the adhesive, the composite film is not completely cooled after the heat sealing roller, and the adhesive layer has a certain fluidity, thereby causing the tunneling phenomenon of the composite film. The solution is to reduce the amount of adhesive applied.

4. The smoothness of the composite film is poor.

The smoothness of the composite film is poor, the friction between the films is large, and the composite is reduced. Film opening performance, handling performance. The main reasons for the poor slipperiness of the composite film are:

1) The curing temperature of the composite film is too high. Treatment method: reduce the curing temperature, the curing temperature should not exceed 50 ° C, if time permits, it can be naturally matured better.

2) The composite substrate has poor slip properties. Treatment method: composite film dusting.

3) Composite membrane moisture absorption. Treatment: Pay attention to the water during storage and transportation. Pay attention to the protection of the composite membrane when the humidity is too high.

5. The composite film wrinkles. Causes the wrinkling of the composite film.

1) The composite substrate itself is wrinkled. Treatment method: Pay attention to check the state of the composite membrane during compounding. If there is uneven thickness, ruffled edge, wrinkle, etc., it will not be used. 2) The unbalance of the guide roller and the composite roller causes the composite film to wrinkle. Treatment method: Check and adjust each guide roller and composite roller to balance.

2) The unbalance of the guide roller and the composite roller causes the composite film to wrinkle. Treatment method: Check and adjust each guide roller and composite roller to balance.