Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

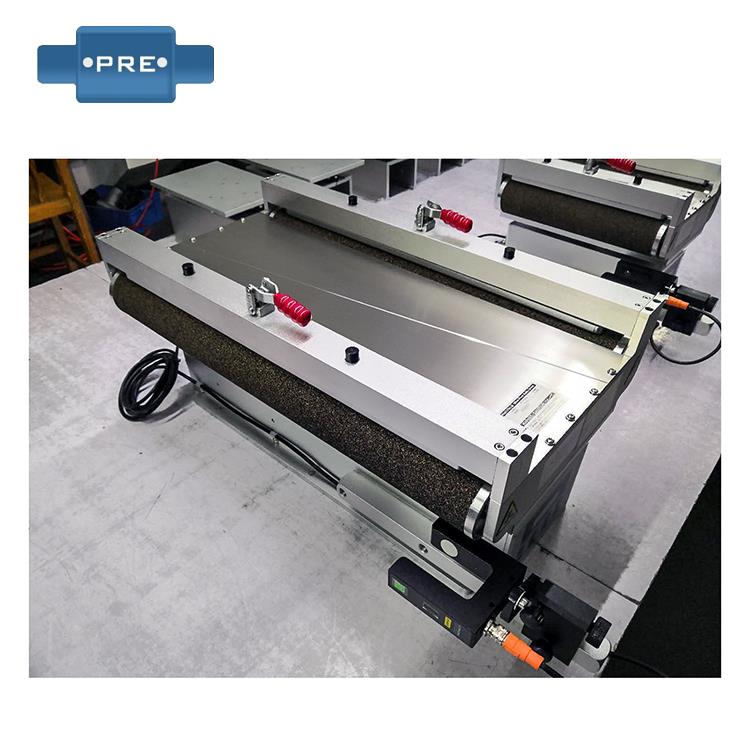

The high-precision, high-speed, high-efficiency coil material automatic processing process of the web guide system has higher and higher requirements for the control of the lateral position of the coil. Equipped with a high-performance automatic web guide system is the key to improving the production capacity and yield of coils. The coil will produce lateral displacement (running deviation) during travel, unwinding and winding, so the guide system can be installed in the above three positions to control the precise passing of the coil.

The system uses high-speed microprocessor, digital, modular, intelligent circuit design; advanced programming, user-friendly interface, LCD screen display; high-performance components and perfect circuit protection design to make the system run continuously and stably; control system response The time is less than 0.01 seconds; the accuracy of the system itself is up to 0.01mm. During the material winding process, the position of the edge or line is detected by the photoelectric sensor to pick up the edge guide system frame or line position deviation signal. Then, the position deviation signal is transmitted to the photoelectric guide controller for logic operation, and a control signal is sent to the mechanical actuator to drive the mechanical actuator to correct the serpentine deviation of the material during operation to ensure linear motion of the material. Optional left and right limit switches prevent the system from running out of control.