Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

After the photoelectric guide generates an electrical signal, it is processed by a digital control CNC, a programmable logic controller PLC, a control system, and the like. These sensors are mainly used in the following areas: machine tools, material processing, motor feedback systems, and measurement and control equipment. The conversion of angular displacement in the guide system uses the principle of photoelectric scanning. The reading system is based on the rotation of a radial indexing disk consisting of alternating light transmissive windows and opaque windows. The system is illuminated entirely by an infrared source such that light projects the image on the dish onto the surface of the receiver, which is covered by a layer of grating, called a collimator, which has the same window as the disc. The job of the receiver is to sense the change in light produced by the rotation of the disc and then convert the change in light into a corresponding electrical change. In general, the rotary encoder can also obtain a speed signal that is fed back to the frequency converter to adjust the output data of the frequency converter.

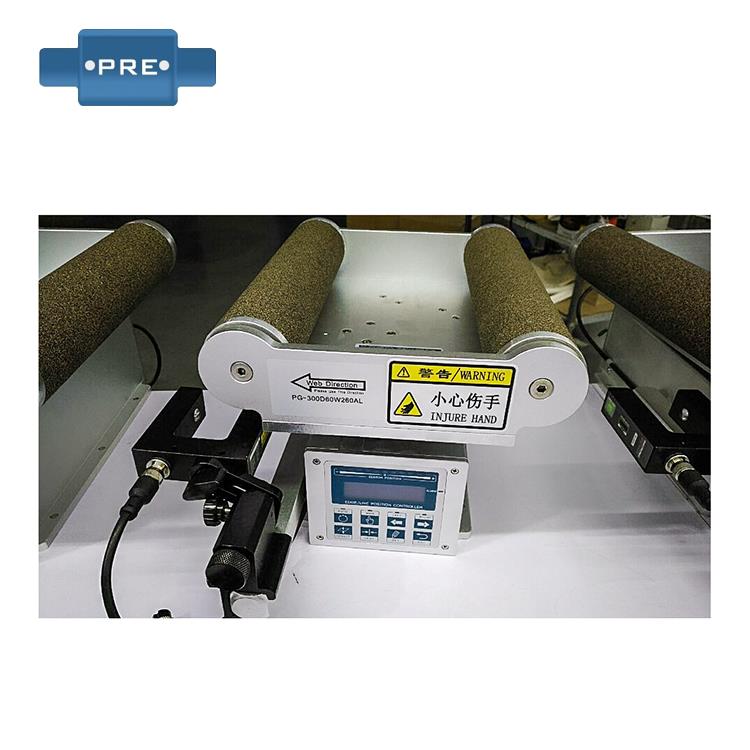

The signal output end of the correcting sensor is connected with the control signal input end of the guiding gas-liquid servo valve, and the liquid inlet and outlet of the guiding gas-liquid servo valve is connected to the oil cylinder through a pipe, the push rod of the oil cylinder is connected with the correcting mechanism, and the guiding sensor is fixed on the sensor bracket. The end of the sensor bracket has a connecting ring, and the connecting ring is sleeved on the lateral displacement adjusting rod of the sensor, and is fixed by the top wire and the lateral displacement adjusting rod of the sensor, and the dividing machine is corrected and connected with the sliding seat with the pulley at the bottom. The sliding seat has a fixing rod, and the fixing rod is detachably connected with the center roll of the raw material. An opto-electricity guide is a device that compiles and converts a signal (such as a bit stream) or data into a signal that can be used for communication, transmission, and storage. The encoder converts an angular displacement or a linear displacement into an electrical signal, the former being called a code wheel and the latter being called a code ruler. According to the readout mode, the photoelectric guide can be divided into two types: contact type and non-contact type; according to the working principle, the encoder can be divided into two types: incremental type and absolute type.

The electric guide is an edge position detecting device (EPC), which is a system for controlling the horizontal position shift of the thin soft material during the conveying process, and has functions of automatic detection, automatic tracking, automatic adjustment and the like. It can track and correct the marking lines or edges of paper, film, non-dry tape, aluminum foil and other materials to ensure the winding and slitting are neat. The system can be used in light industry, textile, printing and dyeing, printing and other industries.