Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

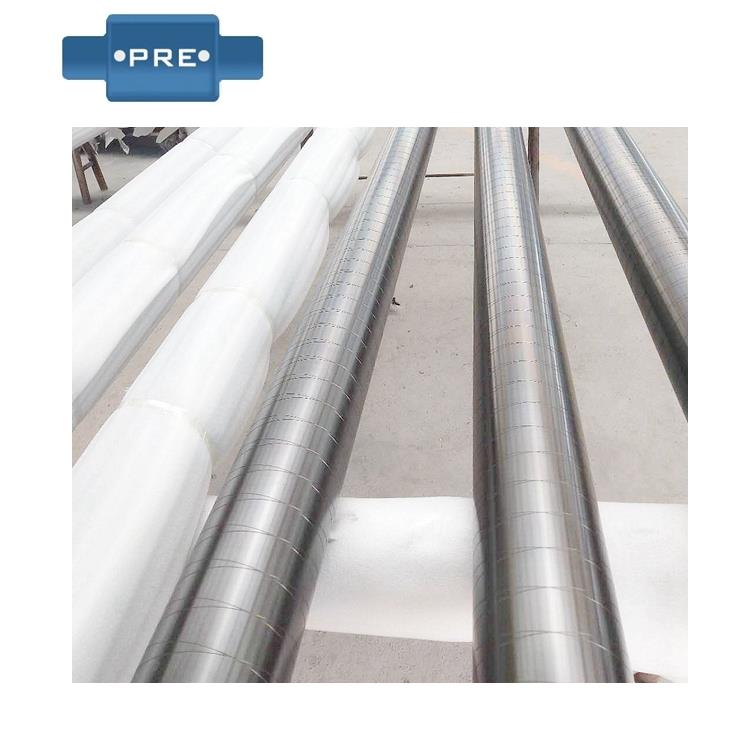

The aluminum alloy guide roller has the advantages of high unit strength, light weight, small inertia, and good appearance of light and rust. It is widely used in embossing printing, coating, winding, blown film, lamination, coating, slitting, paper making, and textile. Waiting for the production line.

The aluminum alloy guide roller produced by our company has passed the strict material extrusion production process. The high strength special section and the reinforced rib can greatly increase the rigidity of the aluminum tube. The excellent hot sleeve installation technology and the appearance of the CNC lathe can make the product high. Contact strength and precision, good linearity and concentricity, accurate high-speed dynamic balance system can ensure static balance and high-speed dynamic balance function (can reach ISO1940 G1 level), ensuring that the aluminum roller does not oscillate at high speed on the machine, and Different surface treatment methods can supply different application needs, and the aluminum roller produced can greatly improve the function of your machine.

The construction of the aluminum alloy guide rolls can be roughly divided into:

(1) Hollow aluminum roller: The inner bearing type structure, the bearing is mounted on the bearing holes in the two faces.

(2) Coupling aluminum roller: The roller body is connected to the steel shaft or the stainless steel shaft end at both ends, and is an integrated structure.

(3) Water-passing aluminum roll: cooling or heating liquid enters and exits through both sides and circulates in the roll body.

(4) Special rolls: Various special construction rolls processed as shown.

Different surface processing methods for aluminum alloy guide rolls:

(1) Glossy: It has the appearance of lubrication and low resistance, and can reach different surface roughness Ra0.3~Ra6.3 according to demand.

(2) Appearance thread: Commonly used are interspersed thread and intermediate unfolded line (extending from the middle to the two sides).

(3) Concave and convex appearance: Various concave, convex and arc-shaped appearances can be processed by CNC lathe.

(4) Sand blasting or shot peening: sand blasting or shot peening can obtain a rougher appearance, which can increase friction.

(5) Knurling or network cable: It can supply different size and appearance of flowers according to customers' requirements.