Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

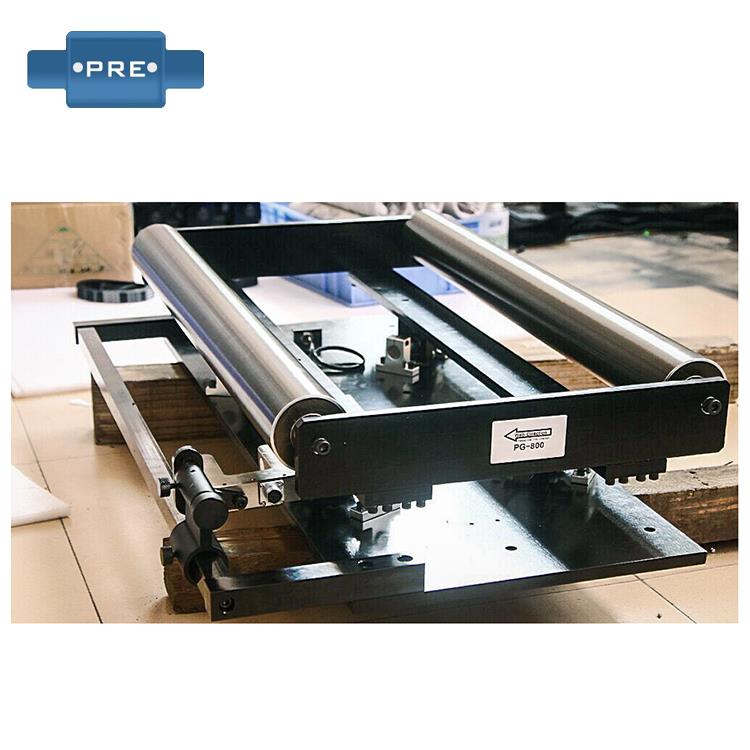

The web guide device manufacturer indicates that the guiding controller is a web guide device for the heat sealing hot-cut bag making machine and the printing machine roll material, and is usually used together with the magnetic powder clutch brake; the guide machine transmits the signal to the guiding controller according to the electric eye, and then the controller The output correction signal is sent to the stepping motor of the servo web guide machine, and the stepping motor drives the screw of the bottom of the machine according to the control signal, thereby achieving the effect of guiding the deviation.

The guide controller is the heart of the electronic web guide system. The guiding controller can correct the various coils and combine them with appropriate sensors, actuators, and other correcting components to help the production line run efficiently and efficiently. Mainly used in printing and packaging, paper, film.

Web guide controller principle: The infrared alignment device is mainly composed of electrical control box, infrared sensor, expander, correction rod and ball screw transmission components. The infrared sensor consists of two components, infrared emission and acceptance.

When the center of the fabric is off center axis, the guide bar will be swung by the ball screw and swiftly swung, so that the center position of the work fabric will return to the original center position, that is, the function of correcting the correction is achieved. At the same time, the expander has the function of expanding the edge of the fabric and expanding the wrinkles and expanding the cloth.

The guiding device manufacturer indicates that the correcting controller CPU adopts 32-bit dual-core (FPGA+ARM) operating frequency up to 168MHz, and the motor drive adopts FPGA-driven stepping motor (no external capacitor resistance commutation, no need to replace the carbon brush), and quick response Time 0.05ms, 260,000 color true color TFT liquid crystal display, using more optimized dynamic PID algorithm control, universal sensor interface can be connected to single / dual photoelectric eye, ultrasonic sensor, CCD sensor.

Previous: Guide Controller Control System Can Change The Guide Speed

Next: About The Fault Judgment And Troubleshooting Points Of Photoelectric Guide Control