Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Magnetic powder brake adopts high quality material, non-magnetic saturated structure and reasonable magnetic circuit design. The product has small volume, large torque, short response time, wide linear range, small torque backlash, and high quality magnetic powder. , resistant to aging. In addition, the well-designed magnetic powder brake heat dissipation structure makes the product have large heat capacity, long service life, long-term operation under severe continuous slip conditions, and high reliability.

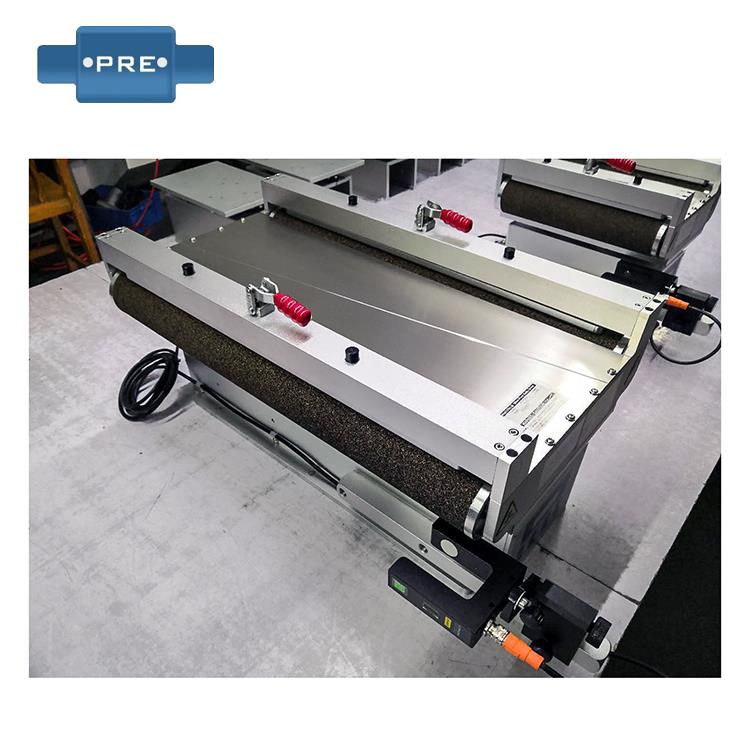

Application of photoelectric guide instrument: laminating machine, laminating machine, printing machine, coating machine, paper machine, dyeing and finishing machine, bag making machine, slitting machine, winding, unwinding and rectification during process.

The photoelectric correcting instrument can be frequency-controlled, automatic tracking, high precision and stable.

Ultrasonic sensors can accurately detect both transparent and opaque coils without adjustment

Low-speed synchronous electric, fast thrust response

No oil pressure and other piping, no oil or oil leakage, easy to clean and maintain

Can be used to make special edges of the inner edge of the roll Photoelectric web guide system is widely used in the horizontal position control of materials in textile, paper, plastic and film manufacturing, packaging, printing, metal foil processing, etc. It can automatically track the marking line or edge of the winding, photoelectric guide The instrument has the advantages of high resolution, good stability, fast response, and strong anti-interference ability. In the photoelectric correction system, if other types of sensors are replaced, a new correction system can be constructed. The drive output can also be changed according to the user's needs to meet different requirements of the user, such as pneumatic and hydraulic corrective action.

Photoelectric web guide system is widely used in the horizontal position control of materials in textile, paper, plastic and film manufacturing, packaging, printing, metal foil processing, etc. It can automatically track the marking line or edge of the winding, photoelectric guide The instrument has the advantages of high resolution, good stability, fast response, and strong anti-interference ability. In the photoelectric correction system, if other types of sensors are replaced, a new correction system can be constructed. The drive output can also be changed according to the user's needs to meet different requirements of the user, such as pneumatic and hydraulic corrective action.

The magnetic powder brake is provided with an excitation coil, and the soft magnetic material and the coil around the air gap constitute a magnetic circuit. The magnetic powder brake is mainly composed of an active rotor, a driven rotor and a fixed support. Some soft magnetic magnetic powder is filled between the active rotor and the driven rotor. When the coil is not energized and the cylinder rotates, the magnetic powder is pressed against the inner wall of the cylinder due to the centrifugal force, and a gap is formed between the magnetic powder and the rotor. The magnetic powder brake does not generate idling torque, and thus generates almost no heat.

Three basic forms of photoelectric guiding:

1, unwinding system

When the photoelectric guide is used for unwinding, the edge or mark of the winding is controlled. When the photoelectric head is fixed at the set winding edge or the tracking line position, the driving device will move the reel to make the winding The edge or marker line remains in this position.

2, winding system

The photoelectric guide instrument is used for winding the winding object, and the photoelectric head and the winding reel are connected as a whole, and a rotating shaft must be fixed between the photoelectric head and the winding reel.

3. Intermediate guiding system

Photoelectric guide are used to offset the bending of the wound in the middle of the process. The photoelectric head of the photoelectric corrector is fixed at the position required for the edge or the marking line, and the control device will drive the guiding shaft to rotate, thereby ensuring that the edge or the marking line of the winding is maintained at the desired position.