Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

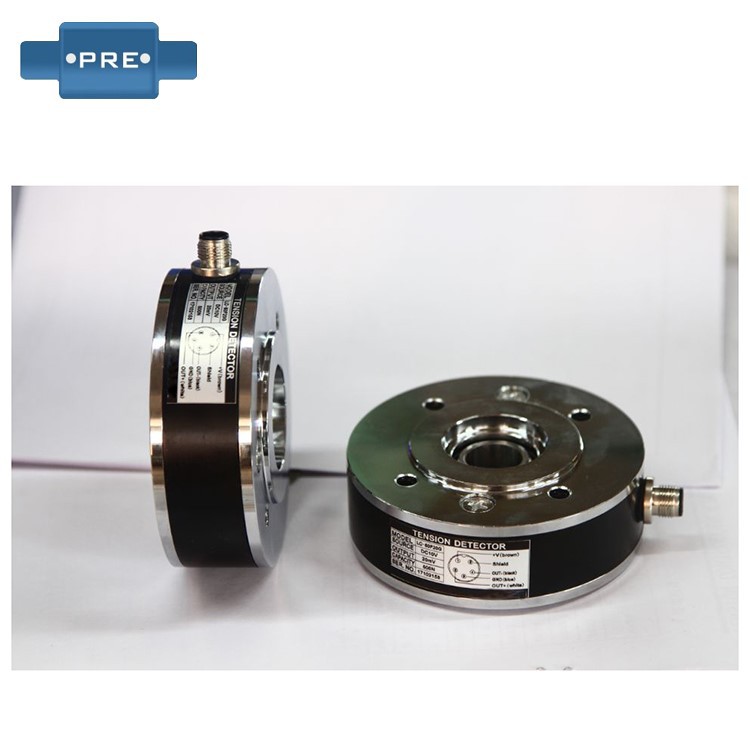

In the manufacturing industry, tension sensors are often used to detect the tension of conveyor belts on the production line to ensure the stability and safety of the production process. By monitoring the tension in real time, it is possible to prevent equipment overload, avoid product quality problems, and improve production efficiency. The tension sensor is an instrument used to measure the tension value of the coil in the tension control process. Working principle: Mainly based on the combination of mechanical deformation principle and electrical principle, the tension change is usually converted into electrical signal output through the response of internal sensing elements (such as strain gauges, piezoelectric elements, etc.) to external forces.

Depending on the application needs, the design and operation of the tension sensor can be different. Here are a few common types of tension transducers:

(1) Strain gauge tension sensor: This kind of sensor senses the change of tension through the strain gauge. Its working principle is based on the coupling of mechanics and electricity, which is to connect the tensile strain gauge and the compressive strain gauge together according to the bridge mode, when subjected to external pressure, the resistance value of the strain gauge will also change, and the amount of change will be proportional to the size of the tension. Due to its simple structure and low cost, strain gauge tension sensors are widely used in industrial automation, mechanical engineering and other fields.

(2) Piezoelectric tension sensor: Piezoelectric materials generate electric charges when they are subjected to force, so they can directly convert tension into electrical signals. Piezoelectric tension transducers have a high sensitivity and are suitable for dynamic load measurements. However, it is sensitive to temperature changes and requires proper temperature compensation.

(3) Optical fiber tension sensor: Optical fiber tension sensor uses optical fiber sensing technology to detect tension by measuring the change of light propagation characteristics (such as light intensity, wavelength, etc.) in the optical fiber. These sensors offer great advantages in precision measurements and high-pressure environments. They can also be measured remotely without the need for traditional wire transmission, making them ideal for complex industrial environments and high-temperature applications.

(4) Capacitive tension sensor: Capacitive sensor reflects the change of tension by measuring the change of capacitance value. It has the advantage of high accuracy and stability, and is suitable for tension monitoring of static or low-frequency vibrations.

Workflow of a strain gauge tension transducer:

(1) The action of tension causes the deformation of the strain gauge: when the tension is applied by an external object, the measuring element in the tension sensor will be physically deformed. This deformation can be bending, tensile or compression, depending on the structure of the sensor and the needs of the application.

(2) The deformation of the strain gauge leads to the change of the resistance value: taking the strain gauge as an example, the common tension sensor contains a group of resistive strain gauges. When tension is applied to the sensor structure, the strain gauge deforms, causing its resistance value to change. Changes in resistance are measured by means of bridge circuits or other signal processing circuits.

(3) The change of the resistance value is converted into an electrical signal output: The change in the resistance of the strain gauge is converted into a voltage signal, which is amplified and filtered through the signal processing unit, and finally outputs an electrical signal that can be read. The magnitude of this signal is proportional to the applied tension, allowing for an accurate measurement of the tension.

(4) Signal processing: In order to improve measurement accuracy and reliability, tension sensors are usually equipped with hardware such as microcontrollers or digital signal processors (DSPs) for real-time data acquisition, processing and calibration. Some advanced tension sensors are also capable of wireless data transmission, facilitating remote monitoring.

Application scenarios and selection points of tension sensors:

(1) Belt tension sensor:

Application scenarios: conveyor belts, transmission belts, etc.

Selection points: Select a sensor with moderate range, high accuracy, and fast response speed, and consider the influence of belt material and operating environment (such as temperature and humidity) on the sensor.

(2) Paper Tension Sensor:

Application scenarios: printing machines, paper machines, slitting machines, etc.

Selection points: Select a sensor with high sensitivity and low noise, and consider the influence of paper thickness, width, and running speed on measurement accuracy.

(3) Weighbridge tension sensor:

Application scenarios: electronic weighbridges, truck scales, etc.

Selection points: Choose a sensor with a large range, high precision and good stability, and consider the size and weighing range of the weighbridge.

(4) Motor tension sensor:

Application scenarios: motor shaft torque measurement, belt tension control, etc.

Selection Points: Choose a sensor that is small, lightweight, and easy to install, and considers the motor speed and torque range.

(5) Strip tension sensor:

Application scenarios: metal strips, plastic films, etc.

Selection points: Choose a sensor with high temperature resistance, corrosion resistance, and anti-interference ability, and consider the strip material, thickness, and running speed.

Contact factory in Guangdong, China

(Over 20 years experience in tension sensor & tension controller system production )

Previous: No Information