Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

A complete set of tension control system is mainly composed of tension detector, tension readout, tension controller, actuator (brake/clutch, servo motor/variable frequency motor, pneumatic/hydraulic device).

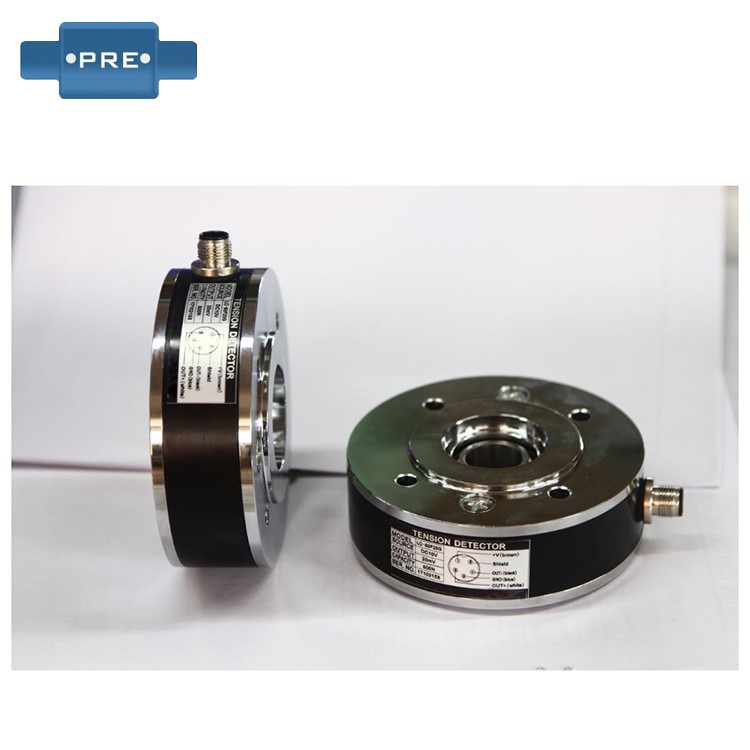

1) Tension sensor

It is used to detect the actual tension value of materials (such as films, paper, metal strips, etc.) in real time and convert them into electrical signals for feedback to the controller. Common types of sensors include pressure sensors, strain gauge sensors, ultrasonic sensors, and more.

2) Tension reader

Used to display real-time tension values.

3) As the "brain" of the system, the tension controller receives the sensor signal and compares it with the preset tension value, calculates the error through the PID algorithm, and outputs the control instruction. Controller types include: manual controller, semi-automatic controller, fully automatic controller.

Manual controller: Depends on manual adjustment, suitable for low-speed or low-precision scenarios.

Semi-automatic controller: (e.g. ultrasonic coil diameter detection): automatic torque adjustment by non-contact method, suitable for mid-range equipment.

Fully automatic controller: combined with tension sensor to achieve closed-loop control, the highest precision, used in high-speed slitting machine, finishing mill and other high-end equipment.

4) Actuators

Magnetic Particle Brake/Clutch**: Controls the output torque by adjusting the current and responds quickly, but the magnetic particle needs to be replaced regularly.

Servo Motor/Inverter Motor**: Dynamically adjusts web tension via speed or torque mode, suitable for high-speed center rewinding and unwinding.

Pneumatic/Hydraulic**: Suitable for heavy, low-speed scenarios, but with low control accuracy.

A complete set of tension control system collaboration processes are as follows:

1) Detection stage

The tension sensor monitors the material tension in real time (the tension readout displays the tension value in real time) and feeds the data back to the controller.

2) Calculation and decision-making

The controller compares the preset value with the actual value, and uses the PID algorithm to generate adjustment instructions. For example, if the tension is insufficient, increase the brake current or increase the motor speed; If the tension is too high, the output torque is reduced.

3) Perform adjustments

Unwinding control: Deceleration by magnetic particle brake or servo motor to prevent the material from being too loose or breaking.

Rewinding control: Dynamically adjust the motor torque according to the change of the reel diameter to ensure constant tension (such as using taper tension control to prevent the inner layer from being extruded and deformed).

Tension control systems play different roles in different application scenarios:

1) Printing & Packaging

Ensure that the paper and film are free of wrinkles or stretch deformation in high-speed printing.

2) Lithium battery manufacturing

Control the tension of the electrode sheet during winding to prevent film wrinkles or dimensional deformation, and improve cell safety.

3) Textile & Non-Woven Fabrics

Maintain the uniform tension of the fabric during the dyeing, finishing and weaving process to avoid breakage or loose rolling.

4) Metal processing

It is used in steel rolling, wire rod drawing and other scenarios to prevent excessive stretching or fracture of materials.

5) Paper and film production

Keep the tension constant during slitting and rewinding to ensure the flatness of the finished product.

6) Special industrial scenes

For example, in the narrow pitch submerged arc welding of aircraft carrier deck welding, the weld is smoothed through tension control.

According to the characteristics of the production materials, the production process, the required production speed and the production

accuracy of the different selection of the appropriate tension control system:

1) Material characteristics: The tension sensitivity of different materials (such as paper, film, metal foil, non-woven fabric) varies greatly. For example, copper foil has a reference tension of 15-25N, while nonwovens only require 5-10N. The target tension range needs to be determined based on the strength, thickness, and ductility of the material.

2) Process scenario: Slitting, printing, winding and other processes have different requirements for tension stability. For example, lithium battery electrode winding requires high-precision closed-loop control, while low-speed packaging equipment may be suitable for open-loop control.

3) Production speed requirements: For high-speed scenarios (such as slitters above 500 m/min), controllers with short response time (such as Delta's ASD-A3-ET servo system, response time of 62.5 microseconds) and high-frequency sensors are required.

4) High-precision requirements: (such as film coating) priority closed-loop system, with full-bridge strain gauge sensor (such as Senming HS-808 controller), the error can be controlled at ±0.05%.

Contact factory in Guangdong, China

(Over 20 years experience in tension control system production )

Previous: What Is A Tension Sensor?

Next: Tension Signal Amplifier