Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

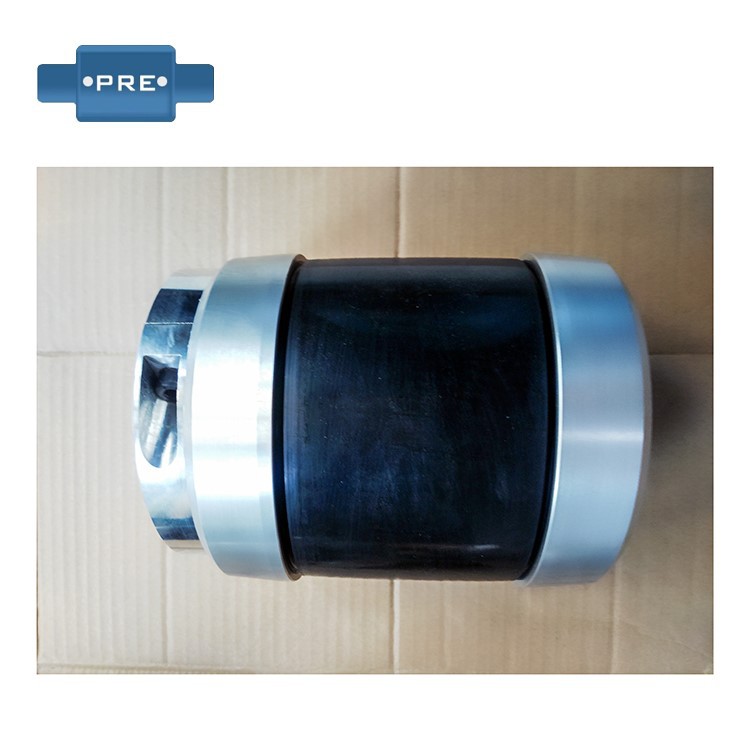

In the coil processing machinery industry, we often use the air shaft, the air shaft adapter is the part that connects the air shaft and other equipment, so that the size of the air shaft can be expanded to fit the size of the core, so what do you need to pay attention to when buying the air shaft matcher?

1) Interface matching and size specifications

Different brands or models of inflatable shafts may have different interface designs, such as threaded specifications or flange connections, if the interfaces do not match, it may cause the inflatable shaft adapter to fail to be installed on the inflatable shaft, or there may be air leakage after installation.

Therefore, it is necessary to determine the outer diameter of the inflatable shaft used in your own factory, the inner diameter of the adapter, the thread type and the flange size.

a. Interface type: Confirm that the interface design of the adapter (thread, flange, quick plug-in, etc.) is fully matched with the interface of the inflatable shaft to avoid installation failure due to metric/imperial and pitch differences.

b. The outer diameter of the inflatable shaft and the inner diameter of the adapter: The inner diameter of the adapter can be determined by measuring the outer diameter of the inflatable shaft to ensure that the adapter can be tightly socketed with the inflatable shaft to avoid being too loose or too tight.

c. The total length and installation space of the adapter: The adapter not only needs to be closely connected to the inflatable shaft, but also needs to be adapted to the structure of the equipment.

2) Working pressure and air source requirements

The inflatable shaft adapter needs to withstand a certain air pressure to maintain the expansion state, so the maximum working pressure of the adapter must meet the working pressure requirements of the inflatable shaft, if the withstand pressure of the adapter is not enough, it may be damaged under high pressure, thus affecting the safety of the equipment; At the same time, the pressure of the air supply also needs to match the air pressure supply of the factory, and if the air pressure supply of the factory is unstable, additional pressure regulating equipment is required.

Withstand pressure range: The adapter needs to be able to withstand the working pressure of the inflatable shaft (usually 0.4-0.8MPa) to avoid rupture under high pressure.

Air Compatibility: Check that the factory air supply pressure is stable and that the adapter requires a regulator or filter.

3) Material and durability

The adapter usually needs to withstand high pressure and frequent inflation and deflation operations, so the choice of material is very important, the common materials are aluminum alloy and stainless steel, engineering plastics, etc. Aluminum alloy is lighter than stainless steel materials, but it is not as durable as stainless steel. Especially in highly corrosive environments, it is necessary to select corrosion-resistant and wear-resistant materials according to the use environment to ensure that there will be no problems in long-term use.

a. Corrosion resistance: stainless steel is preferred in humid or corrosive environments, and aluminum alloy is available for lightweight requirements.

b. Abrasion resistance: In the case of frequent inflation and deflation, the adapter material needs to be anti-wear and prolong the service life.

4) Sealing performance

The tightness of the adapter is directly related to the working efficiency of the inflatable shaft, if the seal is not good, it will lead to air leakage, and the inflatable shaft will not be able to maintain sufficient expansion force, which will affect the fixing effect of the coil. Therefore, when buying adapters, you also need to pay attention to the sealing ring material, such as whether rubber or polyurethane is oil resistant and high temperature resistant; In addition, the design of the sealing structure will also affect the tightness of the adapter.

a. Sealing structure: double sealing (such as O-ring cone seal) is preferred to ensure no air leakage under high pressure.

b. Sealing ring material: high temperature, oil resistant fluoroelastomer or polyurethane material is more suitable for severe working conditions.

5) Ease of installation and maintenance

Whether the adapter is designed to be easy to install and remove, and whether special tools are required for installation and removal, are all factors that will affect the maintenance in the future. Another important factor is whether there are wearing parts that need to be replaced regularly, so you need to consider whether to buy a little more wearing parts when buying an adapter for regular replacement. As technology evolves, some adapters are designed to be modular and allow for quick component replacement and reduced downtime.

a. Quick release design: choose a quick installation structure without special tools to reduce downtime.

b. Replacement of wearing parts: confirm whether the sealing ring and other components can be replaced separately to reduce maintenance costs.

6) Compatibility and Extensibility

If the customer has more than one model of inflatable shaft, then it is necessary to choose a versatile adapter, or see if the manufacturer can provide an adapter.

a. Strong versatility: If you need to adapt to multiple types of inflatable shafts, choose adjustable or modular adapters, or equip with adapters.

b. Shaft diameter adjustment range: Confirm whether the shaft diameter range supported by the adapter covers future needs.

7) Special environmental needs

a. High Temperature/Low Temperature Environment: Temperature-resistant materials (such as high-temperature resistant silicone seals) should be selected at extreme temperatures.

b. Dusty environment

c. Whether anti-static treatment is required

d. In the food packaging industry: food-grade certification requirements are generally required.

8) Cost-effective evaluation

a. Comprehensive cost: Compare the initial procurement cost with the long-term maintenance cost to avoid the hidden cost of low-cost and low-quality products.

b. Bulk purchase discount: long-term demand can negotiate bulk discounts, or choose standardized models to reduce costs.

Contact factory in Guangdong, China

(Over 20 years experience in air expanded shaft adapter production )