Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

The web guiding system is usually used for material guiding on the production line, such as printing, packaging, textile and other industries, to ensure that the material is maintained in the correct position during the transfer process.

Working principle: The guiding sensor detects the relative position of the edge, line or color block of the coil, compares the deviation between the detected value and the set value, and converts it into a proportional signal for correction by the electric drive after the controller program calculation.

The following factors need to be considered when choosing the right web correction machine:

1) Material Type:

Different materials (e.g. paper, film, metal foil, textiles, etc.) have different requirements for the guiding system. For example, ultrasonic waves are better for transparent materials, while reflective materials may require suitable photoelectric sensors.

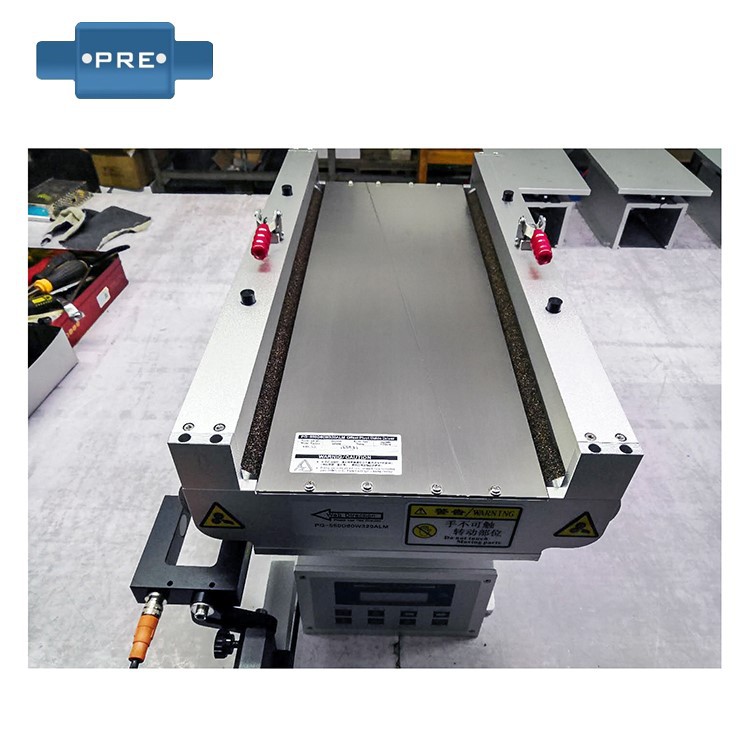

the maximum processing width and thickness of the correction machine need to match the material specifications to avoid the failure of the correction due to the size inconsistency, the manufacturer's suggestion is that the material width is less than 500mm to choose the correction machine, and more than 500mm to choose the correction split machine.

If you choose the correction machine, you also need to determine the direction of the material in and out, and whether the guide roller material should be aluminum or veneer.

2) Production line speed:

The equipment needs to support current and possible future increases in production speeds and avoid becoming bottlenecks.

3) Guiding accuracy:

Select the accuracy level (e.g., ±0.1mm, ±0.5mm) according to the process requirements, and high-precision scenarios (e.g., precision printing) require higher performance equipment.

4) Response speed:

The ability to respond quickly, such as millisecond adjustments, is critical for high-speed production lines to avoid the accumulation of material excursions.

5) Stability:

The equipment needs to be stable over long periods of time to avoid frequent failures or accuracy drift.

6) Sensor Type:

Photoelectric sensors: suitable for opaque materials and low cost.

Ultrasonic sensors: suitable for transparent, reflective or uneven materials.

CCD vision system: used in high-precision scenes, it can identify complex patterns or edges.

7) Type of Actuator:

Pneumatic guidance: low cost, simple maintenance, but average accuracy and response speed.

Motorized web guidance: high precision, fast response, suitable for highly dynamic scenes.

Hydraulic Guiding Equipment: Suitable for heavy materials (e.g. metal coils), but complex to maintain.

8) Installation space:

The size of the equipment needs to be adapted to the layout of the production line, and the horizontal or longitudinal installation method should be considered. The all-in-one machine can be installed up and down, left and right, and the split correction is generally commonly installed horizontally.

9) Load capacity:

The load bearing of the guiding machine needs to match the weight of the material reel (e.g., large metal coils require heavy construction).

10) Environmental Adaptability:

Environments such as high temperature, humidity, and dust need to choose anti-corrosion, dust-proof or high-temperature resistant models.

11) Product cost performance:

In addition to the purchase cost, the maintenance cost and service life should also be considered, and the total cost will be better if the long-term maintenance cost is low.

The all-in-one correction machine is suitable for the following equipment:

Printing and packaging: flexo printing machine, gravure printing machine, rotary printing machine, label printing machine, slitting machine, coating machine, laminating machine, inspection machine, die-cutting machine, film blowing machine, bag making machine, etc.

Non-woven fabrics: sanitary cloth equipment, sanitary pad production line, baby diaper production line, medical accessories production line, etc.

Lithium battery: electrode piece coating machine, pole piece rolling mill, slitting machine, winding machine, etc.

Rubber tires: extruders, cord production lines, presses, cutting machines, molding machines, etc.

Contact factory in Guangdong, China

(Over 20 years experience in web guide system production )

Previous: What Is The Use Of Web Guiding System?