Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

First of all: Plastic film is usually produced by extruding molten plastic into film through an extruder, where rollers may be used to guide the direction of the film, such as guide rollers.

1) Extrusion guide rollers: guide the molten plastic at the exit of the extruder to form the initial film, ensuring uniformity into subsequent processes.

Next there may be calender rolls, which are used to control the thickness and uniformity of the film. Then the cooling rolls, which are used for rapid cooling and shaping. These are the basic steps, and a different type of roller may be required for each step.

1) Calendering rollers: Regulate the thickness and flatness of the film through precise pressure and temperature control (as in cast film production).

2) Cooling rollers: rapidly cool the molten film to set the shape and avoid distortion (e.g. chilled water rollers or chrome-plated rollers assisted by cold air systems).

Then comes stretching and orientation, e.g. in a bi-directional stretching process, rollers may be used for longitudinal and transverse stretching to improve the mechanical properties of the film.

1) Longitudinal stretching rollers: Unidirectional stretching of the film is realized by the speed difference of multiple sets of rollers to enhance the longitudinal strength.

2) Transverse stretching rollers: The film is stretched transversely in the oven by chain clamps and spreading rollers to realize bi-directional orientation (BOPP, BOPET, etc.).

3) Shaping rollers: Stabilize the molecular structure of the film after stretching to prevent retraction.

Next is surface treatment, such as corona treatment rollers, which are used to increase the surface tension of the film for subsequent printing or laminating. This treatment is important for the subsequent processing of the film, so the roller's role here is also critical. In coating and laminating processes, rollers may be used to apply adhesive or to laminate different materials together, such as laminating rollers. This is where the roller may need to have precise temperature and pressure control to ensure an even coating. Also, embossing and texturing is possible, where the surface of the roller is decoratively or functionally textured with an intaglio pattern.

1) Corona treatment rollers: Generate polar groups on the film surface by high frequency discharge to enhance printing/laminating adhesion (e.g. pre-treatment of PE films).

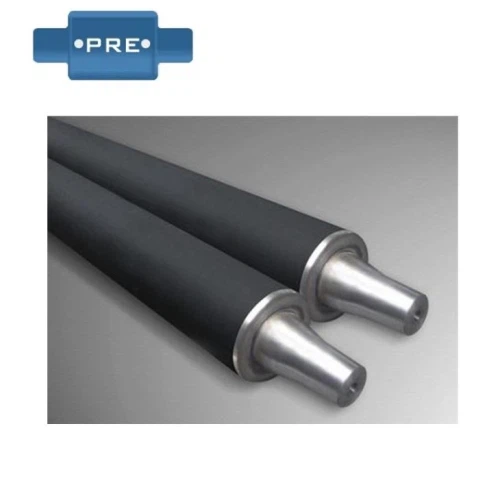

2) Coating Roller: The coating roller is a roller used in the coating process for a wide range of substrates to coat the film. Coating rollers play an important role in printing, coating and other industries to help control the coating thickness and quality. Material: The coating roller is made of high quality 45# steel pipe or alloy steel. Process: tempered by heat treatment, turning, grinding, hard chrome plating, and then fine grinding and high precision grinding and become, or polished to a mirror surface.

3) Embossing rollers: the surface engraved with a specific pattern, giving the film texture (such as leather grain, non-slip texture) or optical effects (such as matte, high gloss).

4) composite roller: in the high temperature or pressure will be multi-layer film (such as aluminum foil, paper) bonding, the formation of composite packaging materials.

5) Hot press roll: Hot press roll technology uses pre-heating of the processed material and roll pressing of the processed material with high-precision temperature-controlled heating rolls. Through precise temperature control, hot roll technology has the advantages of reducing processing pressure, reducing pole piece rebound, enhancing the combination of coating material and fluid collector, and absorbing the heat in the process of roll pressing, etc. (such as dry laminating process). (e.g. dry laminating process).

There are also take-up and unwind rollers, which are the two ends of the production line. The take-up rollers are responsible for rolling up the finished film, while the unwind rollers unroll the raw material. These rollers need to have tension control to prevent the film from

deformation or wrinkling.

1) Tension control rollers: Dynamically regulate the tension of the film in the line to prevent overstretching or wrinkling (e.g., floating roller sensors).

2) Deskew rollers: automatically adjust the lateral position of the film to ensure alignment accuracy (used with photoelectric sensors).

For quality control, there may be measuring rollers that are used to detect film thickness, flatness and other parameters to ensure stable product quality. This part may involve sensors or detection equipment integrated on the rollers.

1) Measuring rolls: integrated thickness sensors (e.g. beta ray or infrared thickness gauges) to monitor film uniformity in real time.

2) Defect detection rollers: with cameras or laser scanners to identify surface defects (e.g. crystal dots, bubbles).

Finally, rollers for special functions, such as anti-sticking rollers to prevent film adhesion, or heating rollers for specific processes. These can be customized for different production needs.

1) Anti-adhesive rollers (silicone rollers): used for the separation of adhesive films (e.g. EVA), non-adhesive, high-strength alloys are prepared on the surface of the roll body by hot-melt coating technology, and this treatment gives the roll body good abrasion resistance to hot-melt adhesives and long service life, as well as excellent anti-adhesive properties.

2) Heating/cooling integrated rollers: achieve zoned temperature control in the casting process to optimize the crystallization process.

Contact factory in Guangdong, China

(Over 20 years experience in rollers production )