Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

There are three main types of air expanded shaft structures:

Leaf-type air expansion shaft: It is composed of two parts: inflatable shaft and long expansion tile, and the expansion part of slat-type inflatable shaft is plate, which can be applied to machinery with high winding precision or lighter winding items.

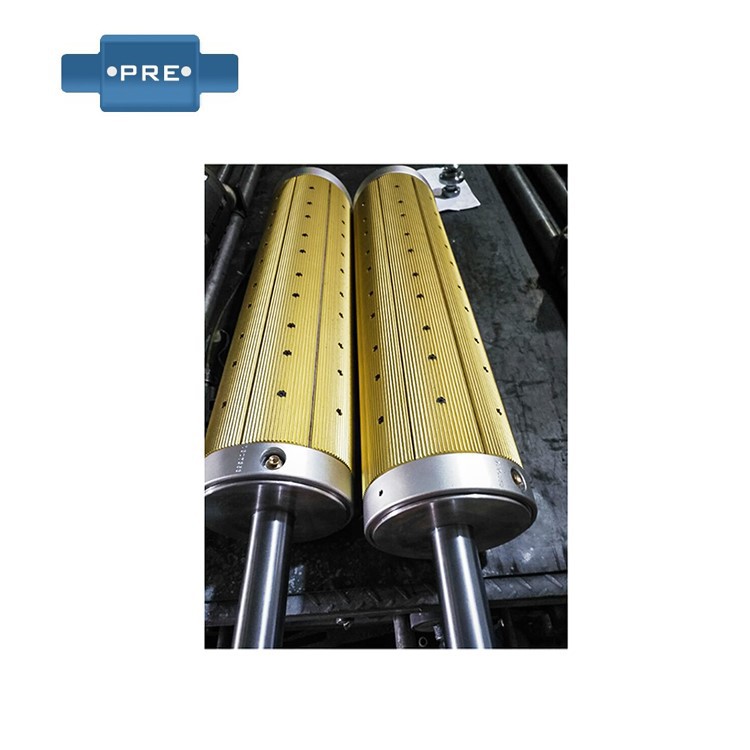

Keybar inflatable shaft: the shaft body is made of high-quality steel pipe, the key bar is cast in aluminum alloy, the shaft body is plated with rub, and imported airbags are used for precise assembly. The expansion part of the key bar type inflatable shaft is a key bar, which can be applied to items with heavy mechanical winding capacity.

Multi-bladder air expanding shaft: through-length key-bar inflatable shaft, rewinding and unwinding can be applied, multi-balloon design, the length of the airbag is similar to the main body of the inflatable shaft. The main body can be made of steel or aluminum, and the key bar can be made of rubber, aluminum or polyurethane. According to the special requirements of the user, other materials are optional. The expansion part of the through-bar inflatable shaft is a through-length key bar, which has the characteristics of high precision, high load-bearing and light weight.

Textile machines mainly include the following types of machines:

(1) Cloth rolling machine: It is used in all kinds of fabrics, non-woven fabrics, foam, leather, paper, reflective materials, acetate cloth, reinforcing tape, conductive cloth and other materials before rolling round packaging and various fabrics before cutting and bundling strips, can be rolled into straight or 45 degree twill fabrics, photoelectric to the edge, thick and thin materials can be effectively aligned automatic control code, can be set:

The pneumatic expanable shaft is used to fix the cloth reel, and the core is evenly clamped by the expansion force of the inflatable shaft to prevent the cloth from slipping or deflecting in high-speed operation. When unwinding, the inflatable shaft can be quickly deflated and contracted, which is convenient for changing the cloth roll and improving production efficiency.

(2) Slitting machine: It is mainly to cut the large drum mother roll into products of different widths, and can have the role of checking the quality of the product.

The inflatable shaft is used to hold the parent reel and the rewinding spool, ensuring that the slitted narrow fabric is wound neatly and avoiding wrinkling or loosening of the edges.

(3) The working principle of the composite machine includes the following four steps:

Coating system: The laminating machine usually consists of two rollers, the upper roller is responsible for applying the paint to the substrate, and the lower roller presses the coating on the substrate.

Drying system: Hot air is blown onto the composite material through a hot blast stove and fan to dry it quickly.

Tension control system: In the lamination process, the tension of the material is adjusted through the tension control system to ensure the stability of the composite material.

Lamination process: After the substrate is coated, it is combined with the adhesive to complete the laminating process. These steps ensure that the laminator can produce high-quality composites efficiently and consistently.

The special properties of the material of the inflatable shaft itself ensure that the coil can still maintain stable transmission in high temperature and high pressure environments.

(4) Coating machine: The working principle includes the following four steps:

Paint supply: The coater conveys the paint (such as ink, adhesive, etc.) to the coating part through the feeding system to ensure the continuity and stability of the coating.

Coating process: The coating machine uses a coating roller or nozzle to evenly coat the paint on the surface of the substrate to ensure the uniformity and quality of the coating. Substrate movement: The substrate is unfolded by the unwinding device and moved forward at a steady speed under the action of guide rollers and tension control.

Coating head design: The design and working method of the coating head determines how the coating is applied, affecting the quality of the final coating.

The role of the inflatable shaft in the coating machine is also to enable the coil to maintain stable transmission in high temperature and high pressure environments.

(5) Loom: The working principle is to form a cloth by interweaving the warp and weft yarns. When the loom is started, the yarn is drawn out of the bobbin and passed through the loom's threading, drawing-in, and the movement of the upper and lower shuttles to form an interwoven cloth. In this process, the various components of the loom work together to ensure the smooth transfer of the yarn and the fineness of the weaving. The working principle of the loom involves a high degree of automation and precision to meet different weaving needs.

The inflatable shaft is used to fix the warp beam or rewind the finished fabric, which is suitable for high-speed operation and frequent roll changes.

(6) Cloth inspection machine: through sensors and computer technology to automatically detect the quality of the fabric, it can quickly and accurately identify the defects on the fabric and improve production efficiency. The working principle of the cloth inspection machine mainly relies on the synergy of photoelectric sensors and computer systems, which mainly includes the following four steps:

Fabric detection: When the fabric to be inspected passes through the cloth inspection machine, the sensor continuously senses and reflects the fabric. The sensor emits light, and the light reflected back from the fabric surface is received by the sensor and converted into an electrical signal.

Signal processing: The electrical signal received by the sensor is converted into a digital signal that can be processed by a computer through a signal converter. The computer analyzes and processes these data according to the preset detection parameters to judge the quality index of the fabric.

Defect identification: The cloth inspection machine can identify various defects on the fabric, such as holes, stains, thread ends, etc. Modern AI fabric inspection machines use deep learning algorithms and image processing technology to identify and classify defects more accurately.

Result output: The test results will be displayed on the screen in real time, or the test report will be generated, which is convenient for enterprises to carry out quality management and decision-making analysis.

The inflatable shaft provides uniform tension in the fabric inspection machine, making it easy to detect fabric defects while reducing manual intervention.

In general: inflatable shafts can be used in the processing of yarn, cloth, etc. on textile machinery. They can provide stable tension control to maintain the uniformity and quality of textiles.

Contact factory in Guangdong, China

(Over 20 years experience in air shafts production )

Previous: How To Adjust The Core Shaft To A Usable State After Repair

Next: What Is The Role Of The Core Shaft in The Production Process Of Lithium Batteries