Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Both mechanical chucks and core expanded shafts are devices used to fix workpieces such as reels, gears, and hubs at the end of the shaft.

There are two main types of mechanical chucks: Pushing mechanical chucks and rotary mechanical chucks.

The working principle of the side-thrust mechanical chuck: when the chuck is subjected to lateral thrust, the key strip expands outward and compresses the coil, and when the thrust is released, the key strip automatically returns.

The working principle of the rotary mechanical chuck: when the front face of the chuck is rotated at a certain angle by the action of the rotating torque, the key bar expands outward and compresses the coiled tube, and when the rotating torque is released, the key bar automatically returns.

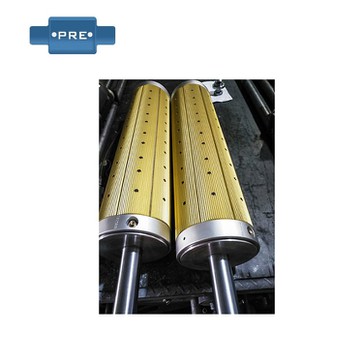

air expanable shaft is a special winding and unwinding shaft, that is, the shaft that can be protruded on the surface after high-pressure inflation, and the shaft that is quickly retracted on the surface after deflation is called an air expansion shaft, and the specifications and dimensions of the inflatable shaft are: 1 inch, 1.5 inch, 2 inch, 2.5 inch, 3 inch, 6 inch, 8 inch, 10 inch, 12 inch, etc. There are three main types commonly used: slat-type inflatable shaft, key-bar inflatable shaft, and through-length key-type inflatable shaft.

The working principle of the leaf type inflatable shaft: when the air nozzle of the inflatable shaft is inflated, the whole plate of the inflatable shaft expands, and the inflatable shaft and the barrel are tightly fixed at this time to achieve a good winding effect; Similarly, it only takes 2 seconds to deflate, at which point the inflatable shaft is separated from the barrel, making it easy to remove the inflatable shaft from the barrel.

The working principle of the lug type inflatable shaft: when the air nozzle of the inflatable shaft is inflated, the key bar of the inflatable shaft expands, and the inflatable shaft and the barrel are tightly fixed to achieve a good winding effect; When deflated, the air bag shrinks, and the key strip retracts back into place under the action of its own elasticity (or auxiliary spring), and the inflatable shaft is separated from the barrel at this time, and it is convenient to take out the inflatable shaft from the barrel.

The working principle of the multi bladder type air expanding shaft: when the air pressure of 4-8kg/cm² is pressurized to the air nozzle of the inflatable shaft for about 3 seconds with its own air source, the airbag expands, and the long expansion block of the inflatable shaft is radially ejected (the long expansion block is usually made of metal or high-strength rubber), and the inflatable shaft is tightly fixed with the material tube to achieve a good winding effect; When the rewinding and unwinding operation is completed, the air core of the air nozzle can be deflated by hand, and the key bar shrinks back to its original position, and the air shaft is separated from the material tube to facilitate unloading.

When the factory machine needs a working device for retracting and unwinding the core, is it more practical to choose a mechanical chuck or an inflatable shaft? We analyze from the following aspects:

(1) Analyze the uniformity and strength of the clamping force

Uniformity of clamping force:

The clamping force distribution of the mechanical chuck is relatively uniform, but due to the influence of the machining accuracy and installation of the taper sleeve, the higher the machining accuracy of the inner hole of the workpiece (such as roundness, taper, dimensional tolerance), the better the clamping effect and the higher the concentricity.

The clamping force of the inflatable shaft is very evenly distributed, the clamping force can be adjusted by air pressure, and the expansion of the airbag can well adapt to the irregularity of the inner hole of the workpiece, so as to avoid stress concentration and damage to the workpiece, so the inflatable shaft is suitable for clamping thin-walled, easily deformed or surface-sensitive workpieces (such as paper tube core, plastic film roll, foil roll)

The strength of the clamping force:

The clamping force of the mechanical chuck is large, the rigidity is very good, and it can transmit very large torque and bear heavy loads, so the mechanical chuck is suitable for ultra-high rigidity occasions, such as machine tool spindles, heavy rolling mills, etc.

The clamping force of the inflatable shaft is usually less than that of a mechanical chuck of the same size, and the rigidity is relatively weak (because the airbag is elastic).

(2) Analyze from the speed of changing rolls and the convenience of operation

The mechanical chuck loading and unloading speed is slow, and multiple bolts need to be tightened or loosened every time the barrel is replaced, which is cumbersome and time-consuming.

The loading and unloading speed of the inflatable shaft is extremely fast: just press a button to inflate/deflate, and the loading and unloading can be completed in a few seconds, which greatly improves production efficiency. Therefore, the inflatable shaft is especially suitable for production lines with frequent replacement of barrels, such as printing machines and slitting machines. For example, it takes 20 minutes for the mechanical chuck to change the roll, and the inflatable shaft for the main time to change the roll is 1 minute, which shows that the difference in the speed of the roll change has a huge impact on the efficiency of the production line.

(3) From the analysis of later maintenance and service life

Mechanical chucks: easy maintenance and long life (virtually unlimited, unless worn or damaged). Generally, it is only necessary to check whether the bolts are loose regularly. And the internal parts of the chuck are very durable.

Inflatable shaft: Relatively complex to maintain. Airbags are consumable parts that can age, wear out, or be accidentally damaged and need to be inspected and replaced regularly. Air circuits and seals also need to be maintained to prevent air leaks. The overall life is limited by the life of the airbag.

(4) From the cost analysis

Mechanical chucks typically have a lower initial purchase cost.

Due to its complex structure, the purchase cost of the inflatable shaft is relatively high. There are ongoing usage costs (compressed air) and potential maintenance replacement costs (airbags).

From the above aspects, it can be summarized:

Mechanical chuck (expansion sleeve): When you need extremely high rigidity, huge load capacity and torque transmission, but do not require high loading and unloading speed, the workpiece itself is strong and the bore accuracy is high.

Selection of inflatable shafts: when you need extremely fast loading and unloading speeds, frequent workpiece changes, clamping thin-walled or vulnerable workpieces (paper rolls, film rolls), high requirements for uniformity of clamping force, but do not require large ultimate loads, and there is a certain maintenance cost.

Contact factory in Guangdong, China

(Over 20 years experience in Mechanical chucks & air shafts production )