Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

In the production of lithium batteries, the air expanded shaft is mainly used as the core component of the winder, which is responsible for clamping and releasing the pole pieces and separators of the lithium battery. The pole piece and separator of lithium battery are usually supplied in the form of coil material, and the thickness of lithium battery pole piece (copper foil, aluminum foil) is only micron pole piece, the material of the pole piece is lithium metal, which is easy to react with air, high temperature or explosion occurs, and the price of lithium metal is high, if it causes a little unnecessary consumption in production slitting, it is a great economic loss, and the inflatable shaft ensures that the coil will not slide or offset during high-speed operation through its unique clamping method, so as to ensure the consistency and stability of the battery.

Because the inflatable shaft is made of specially processed pipes, the stability of the material makes the inflatable shaft (inflatable sleeve) overcome common defects such as deformation and bending in use, and ensures that the production line unit can run stably in the high-speed production state; The inflatable shaft of the future will be more than just a simple clamping device, but may also integrate multiple functions such as web tension control, web web guidance, etc. Through multifunctional integration, the inflatable shaft will be able to better meet the diverse needs of lithium battery production.

How the pneumatic expanable shaft works:

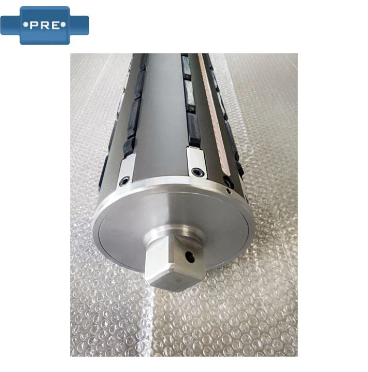

An inflatable shaft is a device that expands or shrinks the shaft diameter by means of gas pressure. It is mainly composed of shaft body, expansion sleeve, sealing ring and gas control system. Under the action of gas pressure, the expansion sleeve expands along the axial direction, so that the shaft diameter can be adjusted.

Advantages of the inflatable shaft itself:

1) Convenient shaft diameter adjustment: The shaft diameter can be quickly adjusted by gas pressure, which can adapt to the production needs of lithium batteries of different specifications, greatly improve production efficiency, and save procurement costs.

2) High precision: The inflatable shaft has high concentricity, which can ensure the accuracy requirements in the production process and improve the quality of the products.

3) Long service life: The inflatable shaft is made of high-strength materials, which has good wear resistance and impact resistance, and has a long service life.

4) Energy saving and environmental protection: The inflatable shaft is driven by gas pressure, without external power, which is energy-saving and environmentally friendly, and is in line with the concept of green production in the new energy industry.

What is the role of an air expansion shaft in a lithium battery production line? We understand the role of the inflatable shaft through the different stages of producing lithium batteries:

1) Battery pole piece production

In the production of lithium batteries, the inflatable shaft is mainly used to adjust the width of the pole piece. By adjusting the shaft diameter of the inflatable shaft, precise control of the width of the pole piece can be achieved, ensuring the dimensional consistency and performance of the battery.

2) Winding of the battery pole piece

In the winding process of the battery pole piece, the inflatable shaft is mainly used to fix the pole piece, and the high concentricity and stability of the inflatable shaft can prevent the displacement of the battery pole piece during the winding process. In addition, the inflatable shaft can also adjust the winding diameter according to the specification requirements of the battery to improve production efficiency.

3) Battery assembly and sealing:

In the battery assembly process, the inflatable shaft is mainly used to connect the battery housing and the cover. By adjusting the shaft diameter of the inflatable shaft, the close fit between the battery shell and the cover plate can be realized, and the sealing performance of the battery can be ensured, so as to prevent electrolyte leakage and improve the safety and service life of the battery.

Common problems and solutions in the use of inflatable shafts:

1) Air leakage problem

a. Reason: The sealing ring is aging, worn or damaged, and the tightness of the inflatable shaft directly affects its clamping effect. If the seal is poor, it may cause the airbag to not expand sufficiently or leak, which will affect the clamping stability of the coil.

a. Solution: Regularly check the sealing ring, find problems and replace them in time, and select high-quality sealing rings to improve the service life.

b. Cause: Airbag leakage.

b. Solution: Replace the key strip, spring sheet, screw, and airbag after the key bar of the inflatable shaft is broken, the spring sheet or screw falls off, and the airbag is replaced; If the air bag and valve are aging because the inflatable shaft has been used for too long, resulting in air leakage, only the air bag and valve need to be replaced.

2) Causes of damage to the expansion sleeve: improper selection of expansion sleeve materials, excessive impact force during use, etc.

Solution: Select the appropriate expansion sleeve material; Optimize the production process and reduce the impact force.

3) Cause of shaft wear problem: the gap between the shaft body and the expansion sleeve is too large, resulting in wear.

Solution: Adjust the gap between the shaft body and the expansion sleeve to ensure concentricity; Regularly check the wear of the shaft body and replace it in time.

Contact factory in Guangdong, China

(Over 20 years experience in air shafts production )