Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

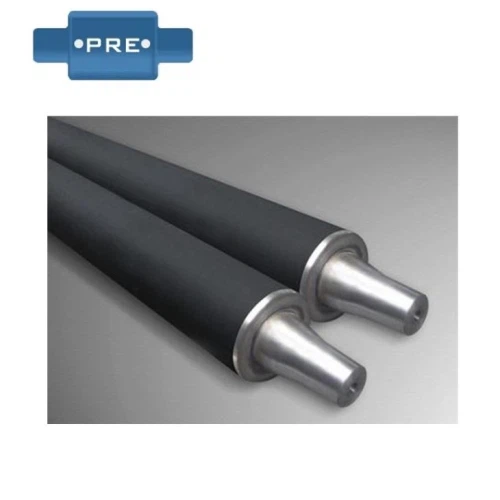

With the further penetration of carbon fiber composite materials in the industrial field, the advantages of carbon fiber rollers have gradually become prominent. Carbon fiber roller refers to the roller made of carbon fiber composite material, and its advantage is to use the lightweight of the material to effectively improve the product performance. Carbon fiber has a small density and light weight, and its specific gravity is 60% of that of aluminum alloy, but its tensile strength can reach more than 3000MPa, and its tensile strength is more than 6 times that of steel. Compared with aluminum alloy rollers, lighter carbon fiber rollers can make the machine start and stop faster, reduce inertia, and increase the speed of the rollers, thereby effectively reducing energy consumption and improving production efficiency.

Advantages of carbon fiber rollers:

(1) Light weight: The density of carbon fiber rollers is low and lightweight, which can significantly reduce the overall weight of the equipment and improve the operation efficiency.

(2) High temperature resistance: The working temperature of the carbon fiber roller is high to ensure the safety during use, its thermal expansion coefficient is small, basically it will not be deformed with the change of working temperature, and the size is stable.

(3) Corrosion resistance: Compared with metal materials, carbon fiber is a non-metallic material with low electrochemical activity, so it has excellent corrosion resistance and aging resistance, is insoluble and swells in acid, alkali, salt and other chemical media corrosion, and can adapt to a variety of working environments.

(4) Low vibration: The characteristics of carbon fiber material make the vibration generated by the roller less during operation, thereby improving the stability of the equipment.

Analyze the strength of carbon fiber drum from three perspectives of carbon fiber material: K, T, and M.

K: tow size

K refers to how many carbon fiber monofilaments are in a bundle of carbon fibers in the carbon cloth where carbon fiber rollers are made. 1K refers to 1000 monofilaments in a bundle of carbon fiber, and similarly, 3K refers to 3000 monofilaments in a bundle of carbon fiber. Carbon fiber roller materials are commonly used in 1K, 3K, 6K, and 12K. In general, the smaller the K number, the lower the intensity. Among them, 3K and 12K are often used in the production of carbon fiber rollers, which are widely used in various industrial fields.

T: Intensity

T stands for the strength of the carbon fiber material. The higher the T-value, the stronger the carbon fiber roller. Common carbon fiber roll materials are T300, T600, T700, T800 and T1000. Among them, the T300 series carbon fiber has low strength and is relatively cheap, which is suitable for fields with low strength requirements.

M: modulus

M stands for modulus, which refers to the stress magnitude corresponding to the unit strain of the carbon fiber roller when stressed, the larger the modulus, the better the elastic modulus, but the lower the strength. The modulus of carbon fiber rollers includes M35J, M50J, and M60J, among which, the modulus of M60J is the largest.

Application areas of carbon fiber rollers:

(1) Application of carbon fiber roller in textile machinery: In the textile process, the roller shaft needs to withstand large radial pressure and friction. Due to the large weight, traditional metal rollers are prone to machine vibration and increased energy consumption. The lightweight nature of carbon fiber rollers can effectively reduce the burden on the machine, reduce energy consumption and improve production efficiency. Good rigidity, allowing the expansion of the width, so that the textile machinery can adapt to the needs of modern production. At the same time, the high wear resistance of the carbon fiber rollers also helps to extend the service life of the rollers and reduce maintenance costs.

(2) The application of carbon fiber roller in printing machinery: In printing machinery, vibration has a direct impact on the printing quality (the greater the vibration, the worse the final printing quality) The low vibration characteristics of carbon fiber materials effectively solve this problem. During the printing process, the rollers need to withstand high-speed rotation and frequent reciprocating motion. This places high demands on the strength and wear resistance of the rollers. The high strength and stiffness of the carbon fiber roller can effectively withstand this high-frequency movement and ensure the stability of the printing quality. At the same time, the low-density nature of the carbon fiber rollers also helps to reduce the overall weight of the machine and increase the operating speed.

(3) In addition, carbon fiber rollers also have a wide range of application prospects in papermaking machinery, plastic machinery and other fields. In these fields, the roller shaft needs to withstand high pressure and friction, and the strength and wear resistance of the material are required.

Contact factory in Guangdong, China

(Over 20 years experience in carbon fiber rollers production )

Previous: What Does An Anilox Roller Do?

Next: What Role Do Rollers Play in The Plastic Film Industry?