Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

In modern industrial production lines, coils of metal strip, film, paper and other materials flow through the production machinery at a very fast speed. These materials are highly susceptible to mistracking during high-speed movements, leading to production interruptions, wasted material, and even equipment damage. The web guiding system is a precision device born to solve this problem, and the precise control of the material is completed in milliseconds. The components of the guiding system: controllers, electric drives, sensors, guiding components. Detection methods: edge inspection, line inspection, centering.

How the web guiding system works:

At the heart of the guiding system lies in its unique closed-loop control system. When the edge of the material is shifted, a high-precision photoelectric sensor can capture a deviation of 0.1 mm in 0.1 seconds and transmit the signal to the central processing unit. The processor uses an adaptive algorithm to calculate the optimal deviation correction scheme according to the material characteristics, running speed, offset degree and other parameters.

The correction system can be divided into a correction integrated machine and a deviation correction split machine:

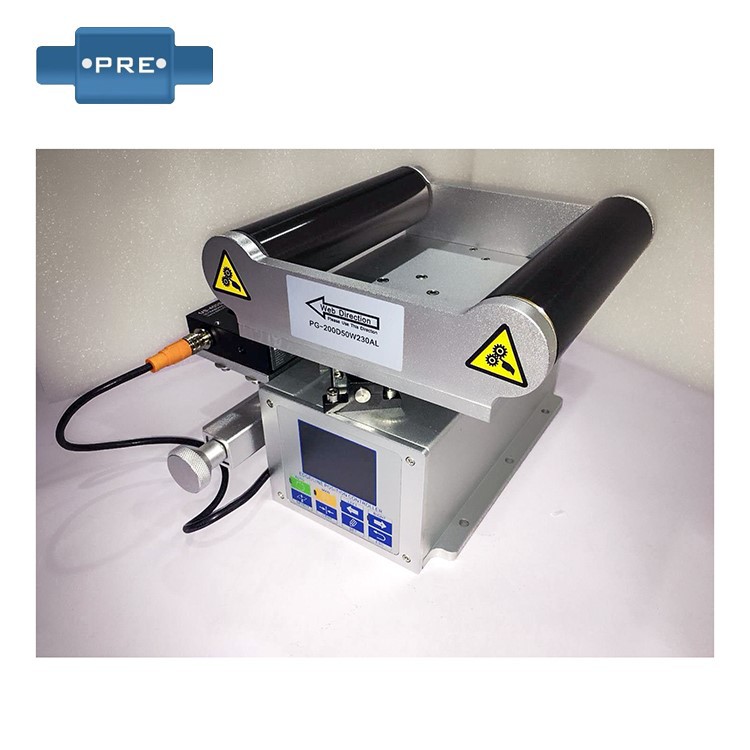

Deviation correction all-in-one machine: the installation method can be installed up and down, left and right. The correction position of the correction all-in-one machine is in the middle of the stroke correction. The all-in-one machine adopts a revolutionary dual-axis linkage system. While the conventional single-axis guiding system can only be adjusted in one direction, the two-axis system enables precise control of the X-Y axis in both directions. This design makes the guiding action smoother and more natural, and avoids the stress concentration or deformation of the material during the correction process. This precise control is particularly important when working with ultra-thin materials. The intelligence of the correction machine is amazing. It is equipped with a teach-in function that memorizes the characteristic parameters of different materials and automatically recalls the optimal parameters the next time the same material is processed. At the same time, it can also realize remote monitoring and fault diagnosis through Internet of Things technology, which greatly improves the reliability and maintenance efficiency of equipment.

Deviation correction split machine: the installation method is commonly used is horizontal installation. The correction position of the deviation correction split machine is at the winding end or the unwinding end. The deviation correction split machine is an automatic closed-loop system that automatically corrects the lateral deviation of the coil. Its working principle is as follows: the guiding sensor detects the relative position of the edge, line or color block of the coil, compares the deviation between the detected value and the set value, and converts it into a proportional signal for the electric drive to correct after being calculated by the controller program. The deviation correction control system is composed of a controller, a side/line sensor, an electric drive, a deviation correction mechanism and other components.

The most basic criterion for choosing a correction machine or a correction split machine: if the material width is within 800MM, the correction machine is selected, and if the width is greater than 800MM, the deviation correction split machine is selected.

Different guide rollers are selected according to the characteristics of the guiding coil:

(1) The coil material is afraid of scratches, so choose an aluminum guide roller with a smooth surface, which will not damage the material;

(2) If the coil requires a certain friction, you can choose to wrap the veneer guide roller, so that the coil will not slip when passing through, which will affect the correction effect;

(3) The coil is sticky, for example, the high-temperature tape needs to be laminated to another material, then you can choose a guide roller with Teflon surface treatment, and the adhesive tape will not stick when it passes through.

In the current situation of industrial production in the increasingly pursuit of high precision and high efficiency, the web correction system plays an indispensable role. It is not only an insurance on the production line, but also a key equipment to improve product quality and production efficiency. With the continuous advancement of technology, the web correction system will surely show its unique value in more and more fields.

Contact factory in Guangdong, China

(Over 20 years experience in web guiding system production )

Previous: What Is A Web Guide Sensor?

Next: What Factors Need To Be Considered When Choosing The Right Correction All-in-one Machine