Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

The pneumatic expanded shaft is a shaft that can be protruded after high-pressure inflation, and the part of the surface expansion body can be quickly retracted after deflating, which is widely used in the field of rewinding and unwinding industry, especially in the printing, textile, and film industries. The size of the inflatable shaft is generally customized according to the size of the commonly used reel, so the size of the air expanable shaft is relatively fixed.

When the size of the drum increases, the size of the inflatable shaft also needs to change the corresponding size, so what is the best solution?

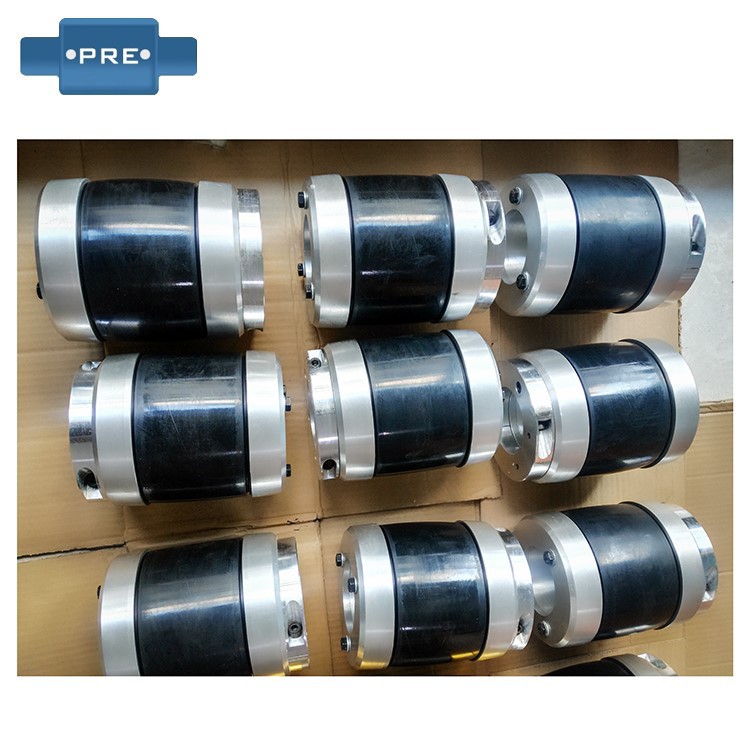

The advent of the air expanding shaft convertors solves this problem very well, because the inflatable shaft adapter is customized according to the existing inflatable shaft size and mounted on the inflatable shaft. The combination of an inflatable shaft adapter and an inflatable shaft is equivalent to a new large-sized inflatable shaft.

At this time, another important question that comes to mind is: which is more cost-effective to re-customize a new size inflatable shaft or to add an adapter of the same size? We need to consider multiple factors from a realistic perspective.

From the input cost factors:

Usually the cost of a custom adapter is lower than that of an inflatable shaft of the same size, because if a new inflatable shaft needs to be designed and manufactured, the sum of materials, machining, air bags, air valves, etc., is much higher than that of a single adapter. Of course, if the existing inflatable shaft has aged or its own performance is not good, from a long-term perspective, it is recommended to directly customize the new inflatable shaft, because the inflatable shaft adapter is attached to the old inflatable shaft and work, and the service life of the original inflatable shaft will directly affect the working time of the adapter.

From technical considerations:

When properly designed and precisely machined, an inflatable shaft adapter can solve basic connection problems and dimensional variations and achieve functionality. However, it is also necessary to consider whether the following potential risks are real, and it is necessary to communicate with the manufacturer of the inflatable shaft and inflatable sleeve. If there are production requirements with high speed requirements, heavy loads, high accuracy requirements, and high concentricity requirements, it is highly recommended to re-customize the new shaft.

1) Increasing the weight of the additional adapter will increase the weight and moment of inertia of the rotating parts, which may affect the start, stop performance and energy consumption of the equipment (especially high-speed equipment), and even cause additional burden on the drive motor and bearings;

2) It may also affect concentricity and dynamic balance: The machining accuracy, installation tolerance and fit of the adapter with the original shaft are very easy to introduce eccentricity or dynamic balance problems. This can lead to increased vibrations during operation, affecting product quality (e.g. print registration, film/paper tension fluctuations), accelerated bearing wear, and noise.

From the time factor:

Custom adapter design and manufacturing is usually faster because the inflatable shaft adapter drawings are simpler and have shorter cycle times than inflatable shafts. Customizing an inflatable shaft involves multiple steps such as design communication, selection, machining, assembly, and testing, and the whole cycle is slightly longer. If you are on a tight budget, opting for a custom inflatable shaft will be more suitable.

If you don't know too much about the production needs of your factory, or are struggling with which solution to choose, you can contact PRE China Factory - air Shaft and core shaft adapter Manufacturer, have professional technicians and sales staff to patiently solve your problem.

Detailed information on the interface size (shaft diameter, keyway, flange size, positioning requirements), equipment operating parameters (maximum speed, maximum tension/torque), and application scenarios of new and old tooling can be provided to professional inflatable shaft manufacturers. Based on experience, manufacturers can give specific advice and quotations on the feasibility of adapters, the risks, and the option to customize new shafts.

Contact factory in Guangdong, China

(Over 20 years experience in air shafts & core adapters production )