Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

First of all, let's understand what machines are mainly included in printing equipment? Generally, there are offset printing machines, gravure printing machines, and flexo printing machines.

Offset printing machine: It is a kind of lithographic printing machine, which prints graphics and texts from the printing plate to the rubber cylinder, and then transfers from the rubber cylinder to the paper.

Gravure printing machine: It is a machine that uses gravure for printing, mainly used for flexible packaging printing. In the middle of the two-stage traction of the gravure printing machine is the printing unit, which has very high requirements for color registration accuracy and requires high stability tension adjustment. The main motor and two-stage traction require closed-loop control with tension feedback.

Flexographic printing machine: using fluid ink with strong fluidity, the ink is transmitted to the graphic part of the printing plate by the ink fountain rubber roller and the anilox ink transfer roller and inking, and then the printing pressure is applied by the pressure cylinder to transfer the ink on the printing plate to the substrate, and finally the printing process is completed by the drying surface. It is characterized by the simple structure of the machine, so it is easy to operate.

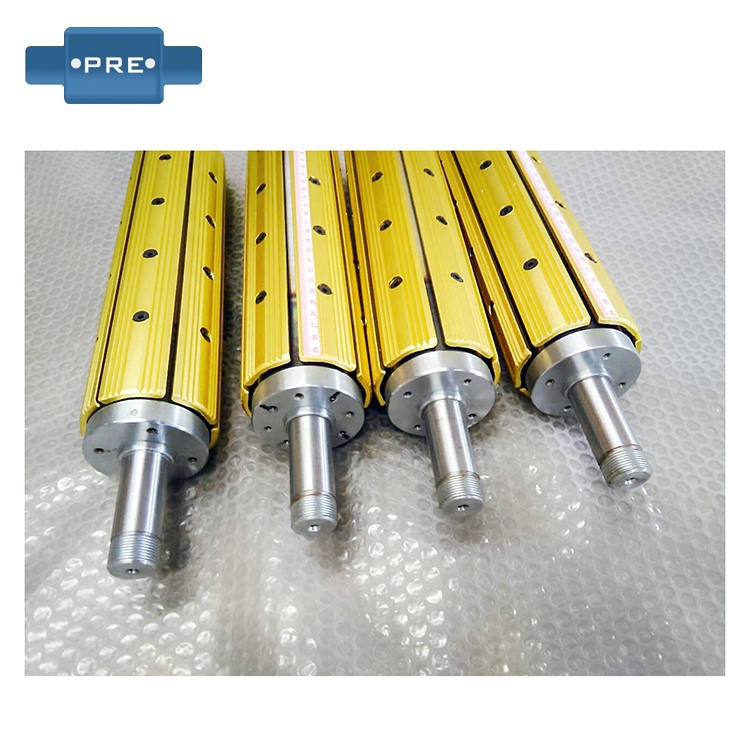

What is the role of an air expanded shaft in a printing device?

The inflatable shaft is an important component in the printing equipment, which is mainly used to support the printing cardboard and complete the actions of retracting, releasing and transmitting the paper. The working principle of the inflatable shaft is to compress the air into the shaft core, so that the rubber airbag of the shaft core expands, so as to be in close contact with the cardboard to achieve the purpose of supporting and transmitting the action. When the inflatable shaft is working, the compressed air enters the airbag in the shaft core through the airway, which inflates the airbag, thereby pushing the shaft core to expand outward and tightly bind with the cardboard. Since the expansion coefficient of the inflatable shaft is small, it is possible to achieve high-precision printing results.

How many pneumatic expanable shafts do I need for a printing machine?

Different types of printing equipment may use different numbers of inflatable shafts, and in general, a basic printing equipment may have one unwinding and one winding section, so two inflatable shafts are required. However, if it is a more complex equipment, such as a double unwinding or double winding design, more shafts may be required. For example, some equipment may process two materials at the same time, or there may be intermediate drying stages that require additional tension control, which may increase the number of inflatable shafts. In general, 2-4 inflatable shafts can meet the basic needs of most printing equipment, but the specific number needs to be determined according to the equipment design, process complexity and automation level.

1) General application scenarios:

Ordinary flexo printing machine: 2-3 (unwinding, printing, winding).

Gravure printing machine: 3-4 pcs (unwinding, multi-color group tension control, winding).

Slitting and rewinding machine: 2-4 pieces (more unwinding or more winding after slitting).

2) Distinguish according to the degree of automation:

Manual/semi-automatic equipment: the number of inflatable shafts is small (2-3), relying on manual roll changing.

Fully automatic equipment: more than 4 may be required (e.g. A/B unwinding system with automatic roll change or double winding unit).

3) According to the material and process requirements:

Special materials (e.g. films, aluminum foils): high requirements for tension control, which may increase the auxiliary adjustment of the inflatable axis.

High-speed printing or wide-format equipment: Multiple inflatable shafts may be required to spread the load and ensure stability.

Printing equipment manufacturers need to consider many aspects when purchasing air shafts, such as the use environment, working status, etc.If it is used for the unwinding end, the total weight of the coil is not very heavy, you can choose the plate air shaft, if it is heavier, the key air shaft or the through bar air shaft is more suitable; For the winding end, if it is generally not very heavy, choose a plate air shaft.

When using printing machines in printing factories, the following two points need to be noted:

1) It is necessary to pay attention to the selection of the appropriate air pressure, the air pressure is too high or too low will affect the use of the inflatable shaft, and the appropriate air pressure should be selected according to the actual situation of the equipment.

2) Choose the right material, you should choose the appropriate inflatable shaft according to the material and thickness of the printed cardboard, and ensure that the inflatable shaft can be in close contact with the cardboard. When installing the inflatable shaft, it should be operated in accordance with the instructions of the equipment to ensure that the inflatable shaft can operate normally.

Contact factory in Guangdong, China

(Over 20 years experience in air shafts production )

Previous: What Does The Core Shaft Do On The Coater

Next: How Many Air Shafts Do You Need For A Packaging Machine