Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

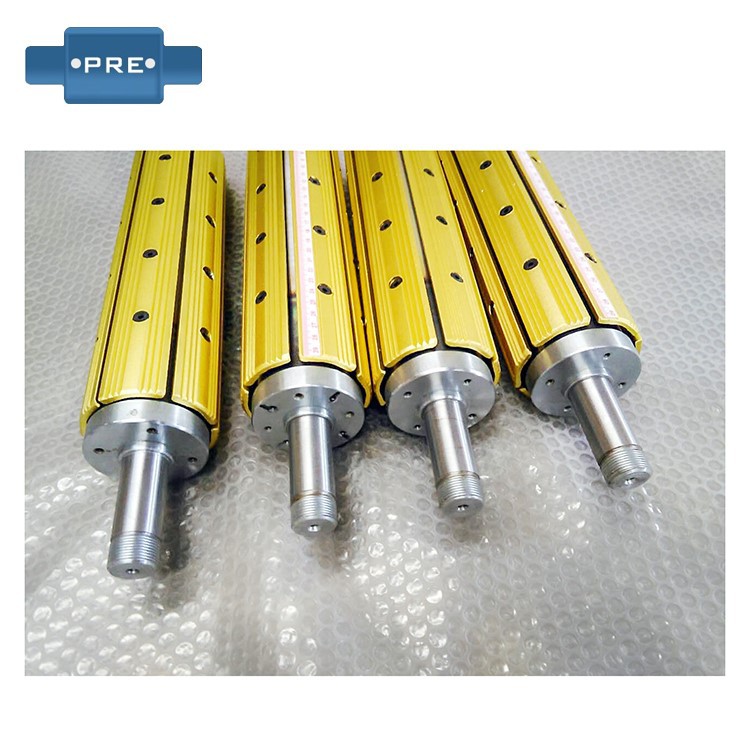

First of all, let's understand the working principle and basic characteristics of the following core expanding shafts:

The working principle of the inflatable shaft: it is to achieve its function by inflating and deflating and contracting. Usually made of steel, aluminum alloy and other materials of the inflatable shaft with a built-in airbag, when the air enters the airbag through the air valve, the outer diameter of the airshaft will expand; When deflated, the outer diameter shrinks back to its original shape.

The above simple and effective principles give the inflatable shaft a number of excellent properties: the details are as follows.

1) Efficient clamping:

The inflatable shaft can realize the rapid expansion and contraction of the shaft in a short time, and complete the tightening and loosening of the core. Its efficient clamping method not only improves the speed of roll change, but also reduces manual operation time, which greatly improves the efficiency of the production line.

2) Uniform force:

Because the inflatable shaft can form a uniform circumferential force when expanding, it can avoid problems such as uneven winding and edge wrinkles caused by uneven force, so as to ensure the quality of the product.

3) Adaptable:

The inflatable shaft is suitable for cores with different inner diameters, and manufacturers only need to replace the airbags of different specifications to adapt to the changes. Moreover, the size and specification of the inflatable shaft can be customized according to the needs of customers to meet the needs of different production processes.

4) Durability and easy maintenance:

Since the material selected for the inflatable shaft usually has a high resistance to wear, and the airbag can be replaced separately, there is no need to replace the entire shaft body when the airbag is damaged, which greatly reduces maintenance costs and time.

In the packaging industry, inflatable shafts are used in a wide range of applications and mainly play the following roles:

1) Coiled packaging material:

Inflatable shafts are commonly used to wind various packaging materials, such as film, paper, aluminum foil, etc. In these applications, the inflatable shaft can effectively maintain the uniform tension of the material, prevent the longitudinal shrinkage and lateral expansion of the material during the winding process, avoid the tensile deformation, uneven thickness or wrinkles of the material, and ensure the flatness and aesthetics of the wound product.

Application scenario: The inflatable shaft is linked with the control system through the tension sensor to achieve real-time dynamic adjustment to meet the needs of high-speed production.

2) Unwinding and centering system:

In the automatic packaging production line, the inflatable shaft is used to drive the unwinding of the coil, and by accurately controlling the unwinding tension and speed, it can avoid the circumferential slippage caused by excessive tension, prevent the material from misaligning, and improve the production accuracy. The fast roll change capability of the inflatable shaft and its adaptability to different roll diameters make it an important part of an automated packaging line.

3) Slitting Machinery:

In the slitting machine, the inflatable shaft is used to support and clamp the mother coil material, and quickly remove the slitted small rolls after the slitting is completed. It not only improves the slitting efficiency, but also ensures the stability of the material tension during the slitting process, and avoids the unevenness of slitting and material waste.

4) Rewinding Equipment:

In rewinding equipment, the inflatable shaft is often used to rewind the whole roll of different sizes, and its excellent adaptability and fast rewinding characteristics make the rewinding process easy and efficient.

Taking the application of the inflatable shaft in the stretch film packaging machine as an example, the matters that need to be paid attention to in the maintenance of the inflatable shaft are understood:

Regular inspection: Regularly check whether the airbags, air valves, key bars and other parts of the inflatable shaft are damaged or worn, and replace them in time if there is a problem. Inspect the surface of the shaft for scratches or deformations, and repair or replace if necessary.

Cleaning and maintenance: Regularly clean the surface of the inflatable shaft to remove dust and dirt and keep the shaft clean. Avoid the use of aggressive cleaning agents to avoid damage to the shaft surface.

Installation and use: When installing and removing the film roll, it is necessary to follow the correct operation method to avoid damage to the inflatable shaft due to improper operation. During use, avoid overstretching or twisting the stretch film to avoid excessive pressure on the inflatable shaft.

In the packaging industry, the pneumatic expanable shaft is not only the core component of coil transport, but also the cornerstone of efficient, accurate and safe production. Its technological innovation (such as intelligence and modularization) continues to promote the upgrading of the packaging industry in the direction of automation and greening, and has become an indispensable "intelligent hub" for modern packaging equipment.

Contact factory in Guangdong, China

(Over 20 years experience in air shafts production )