Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

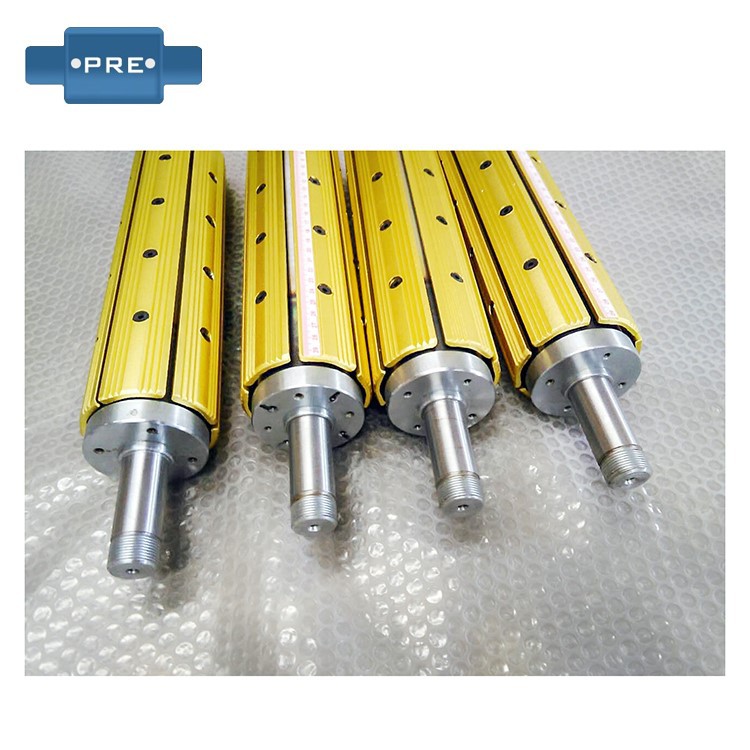

An pneumatic expanabe shaft is a shaft-shaped tool specially used for coil rewinding and unwinding, which expands the shaft body by inflating it, so as to firmly hold the paper roll or other roll material. Its working principle is to use the principle of air pressure expansion to expand the surface of the shaft by inflating, so as to clamp the drum firmly; The shaft diameter is reduced after deflation to facilitate the removal of the reel.

Printing label machines are widely used in packaging, food, medicine and other industries to make various labels. Because the labels produced have different textures and need to change the roll frequently, this puts forward high requirements for the fixation and replacement of the roll. It is in this context that the inflatable shaft is widely adopted, which is mainly reflected in the following points:

1) Efficient and convenient: The design of the inflatable shaft allows for quick loading and unloading of the drum material, which greatly improves the production efficiency. The drum can be fixed and released with a simple inflation and deflation operation without the need for complex mechanical adjustments.

2) Uniform clamping: The inflatable shaft is able to expand evenly after inflation, thus providing a uniform clamping force over the entire length of the shaft. This uniform clamping force ensures the stability and balance of the web material at high speeds, reducing material damage and waste.

3) Strong adaptability: the inflatable shaft is suitable for a variety of roll materials of different materials and thicknesses, including paper, plastic film, metal foil, etc. Its design can be adapted to different application needs to accommodate different diameters and widths of reels.

4) Reduced material damage: Since the inflatable shaft provides an even and adjustable clamping force, it is able to minimize damage to the web material, especially when handling sensitive or fragile materials.

5) Easy maintenance: The structure of the inflatable shaft is relatively simple, and the maintenance and cleaning work is easy to carry out. Regular inspection and maintenance can ensure its long-term stable operation.

6) Economical and practical: Although the initial investment of the inflatable shaft may be higher, its efficient production capacity and reduced material waste can save the enterprise costs in long-term use.

Safe and reliable: The operation of the inflatable shaft is safe, which reduces the labor intensity and safety risk of the operator when loading and unloading the reel. At the same time, its reliable performance guarantees the continuity and stability of the production process.

Key Factors for Customizing an Inflatable Shaft:

1) Material selection: The inflatable shaft is usually made of aluminum alloy, carbon steel, stainless steel and other materials. The difference in the performance of different materials will directly affect the durability and service life of the equipment. Depending on the material of the coil and the processing environment, choosing the right material is the first step in customizing the inflatable shaft. For example, for high-temperature or corrosive environments, special alloys or coatings may be required to improve the durability and corrosion resistance of the inflatable shaft.

2) Size and specification: The size and specification of the inflatable shaft need to be determined according to the width, thickness and maximum coil diameter of the coil, and the specifications of the inflatable shaft include length, diameter, bearing capacity, etc. The customized design ensures a perfect match between the inflatable shaft and the coil for improved clamping results.

3) Operation mode: The customized inflatable shaft can also be designed according to the convenience of the operator, such as automatic inflation/deflation system, remote control operation, etc., to improve operation efficiency and safety.

4) Performance requirements: Customized inflatable shafts need to meet specific performance requirements, such as clamping force, response speed, number of cycles, etc., to ensure reliability and stability in specific industrial applications.

Illustrate the application of core expanding shafts in the following three industries:

1) In the textile industry, customers need an inflatable shaft that can adapt to different fabric thickness and tension requirements. Through customized design, we provide an inflatable shaft with adjustable clamping force, which allows customers to adjust the clamping force according to their actual needs, thus improving production efficiency and fabric quality. The inflatable shaft can also be used to control the tension of the fabric to ensure the flatness and consistency of the fabric in dyeing, printing and other processes.

2) In the printing industry, the challenge for customers is to quickly change rolls of different sizes. We customized a quick-loading and unloading inflatable shaft that greatly shortens the time to change the coil and improves production efficiency through a simplified loading and unloading mechanism and an optimized clamping structure. As the core component of the support material, the inflatable shaft can also ensure that the tension of paper, film and other materials is uniform during the printing process, thereby improving the printing quality.

3) In the food packaging industry, customers need an inflatable shaft that can withstand high humidity environments. We have adopted special corrosion-resistant materials and designed structures with better sealing performance to ensure the stability and durability of the inflatable shaft in high humidity environments. Among them, the 3-inch inflatable shaft is often used to drive the sealing and wrapping actions of the packaging machine.

Contact factory in Guangdong, China

(Over 20 years experience in air shaft,roller production )

Previous: What Role Does The Air Expanded Shaft Play in The Packaging Industry?

Next: The Future Development Trend Of The Core Expanded Shaft