Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

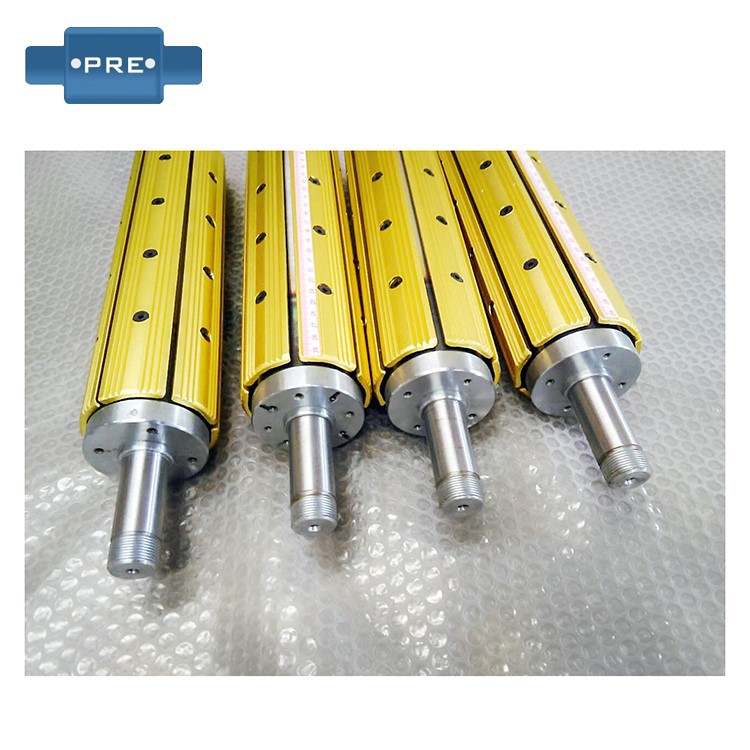

An air expanable shaft is a key component used in coil processing equipment to achieve the tensioning and release of the coil through a change in the internal gas pressure. In recent years, with the development of automation and precision machining technology, the design and performance of inflatable shafts have been significantly improved. In the current market, inflatable shafts not only excel in terms of durability and stability, but are also able to accommodate the needs of high-speed operation and frequent web changeovers. In addition, with the application of IoT technology, remote monitoring and maintenance of inflatable shafts has become easier.

The working principle of the inflatable shaft can be divided into three main steps: gas supply, gas expansion, and gas contraction.

Gas supply: The air supply for the inflatable shaft is usually supplied by a compressed air system. The compressed air enters the cylinder through the pipe, and the entry and stop of the gas is controlled by the air valve.

Gas expansion: When the air source enters the cylinder, it will drive the piston in the cylinder to move outward. The movement of the piston will drive the rotation of the drive shaft, so as to realize the transmission function. The piston in the cylinder is usually connected to the drive shaft and transmits the force through a connecting rod.

Gas shrinkage: When the gas supply stops, the gas in the cylinder will be released, and the piston will return to its initial position due to the action of a spring or other device. This process is the contraction of the gas. When the piston returns to its initial position, the drive shaft also stops rotating.

The future development direction of the pneumatic axis:

In the future, the development of inflatable shafts will pay more attention to intelligence and efficiency improvement.

1) With the advancement of sensor technology, the inflatable shaft will integrate more sensors to monitor the status of the shaft in real time, realize predictive maintenance, and reduce downtime.

2) As the requirements of automated production lines become higher and higher, the inflatable shaft will need to further improve its response speed and accuracy to adapt to the more demanding coil processing process.

3) With the progress of material science and the development of precision machining technology, inflatable shaft products are evolving in the direction of lightweight and high strength to reduce the overall weight and improve their load capacity. For example, a new generation of inflatable shafts made of carbon fiber composite materials is 40% lighter than traditional metal materials, but 50% stronger, which greatly meets the needs of modern manufacturing for lightweight equipment.

Future market size and demand changes for inflatable shafts:

With the continuous improvement of the global industrial automation level, the market demand for inflatable shafts, as one of the key components in automated production lines, continues to grow. The global inflatable shaft size is expected to increase to $2 billion by 2027, growing at a CAGR of about 6%.

The main areas of application of inflatable shafts:

1) Printing industry: occupy 30% of the market share, and the demand is increasing year by year. The inflatable shaft can quickly change paper or film rolls of different sizes, significantly reducing the changeover time and increasing production efficiency.

2) Packaging industry: accounting for 25%, in recent years, with the rapid development of e-commerce logistics, the demand for efficient packaging equipment has surged, which has promoted the wide application of inflatable shafts in this field.

3) Textile industry: accounting for about 20% of the total market, especially in high-speed looms, the application of inflatable shafts effectively solves the problem of easy sliding of traditional shafts and ensures the consistency of fabric quality.

Take the 6-inch inflatable shaft specification as an example to introduce its specific parameters:

The 6-inch inflatable shaft is a standard size commonly found in industrial equipment and is used to hold and control the position and movement of the shaft. The following will introduce the specifications, standard dimensions and applications of 6-inch inflatable shafts.

1) Dimensional parameters

The standard size of a 6-inch inflatable shaft usually includes parameters such as diameter, length, load capacity, etc. The diameter is generally 6 inches (about 152.4 mm), and the length can be determined according to specific needs, generally ranging from tens of centimeters to several meters. The load-bearing capacity depends on the material and structural design, and can generally withstand large axial and radial loads.

2) Material selection

The main material of the 6-inch inflatable shaft is usually high-strength alloy steel or stainless steel, which has excellent mechanical properties and corrosion resistance. The selection of materials is determined according to the actual application environment and use requirements to ensure the stability and reliability of the shaft.

3) Structure and process

The structure of the 6-inch inflatable shaft generally includes shafts, shaft sleeves, balls, sealing rings and other parts. The shaft is the main part of the whole shaft, usually a cylindrical rod, with certain precision requirements. A bushing is a part that is sleeved on the shaft to reduce the friction between the shaft and the ball. Balls are components that are subjected to axial and radial loads, usually made of high-quality steel and heat-treated to improve hardness and wear resistance. The sealing ring is used to prevent dust, liquid and other impurities from entering the shaft and protect the normal operation of the shaft.

Contact factory in Guangdong, China

(Over 20 years experience in air shaft production )

Previous: Application Of Air Shaft On Printing Label Machine

Next: An In-depth Analysis Of The Structural Drawings Of The Air Shaft