Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

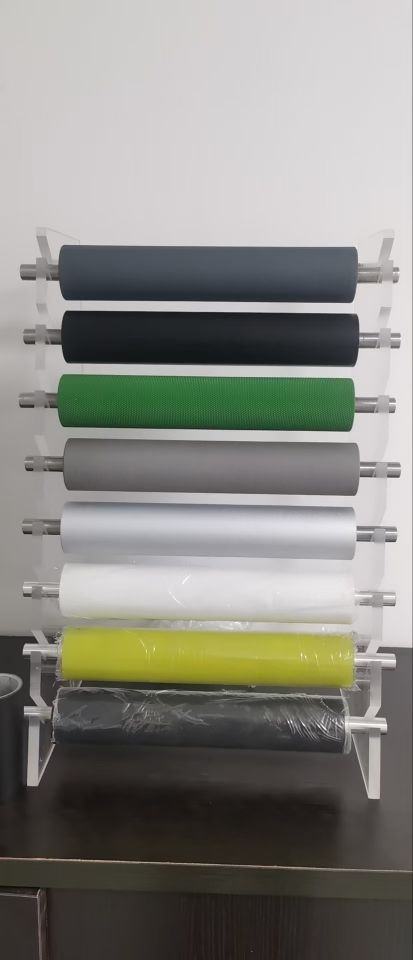

Banana bending roller is a commonly used part in industrial equipment, and it is widely used in many industrial and mechanical applications, especially in application scenarios such as pressure, tension, bending control, etc., such as printing, packaging, papermaking, textiles and other industrial fields. At present, the arc roller is divided into two kinds of fixed arc roller and variable arc roller, and is divided into rubber surface arc roller (rubber surface usually uses nitrile, silicone, EPDM rubber) and metal surface arc roller according to the roller surface material. The arc roller is mainly composed of an arc mandrel, a rolling bearing assembly, a rubber sleeve, an end sleeve, a bearing and an adjusting wheel.

Features of Banana Roller:

1) Adjust the tension. The curved shape of the banana roller helps to adjust the tension of the material during processing, ensuring a smooth movement of the material.

2) Transmission of materials. On some production lines, banana rollers are used to transfer materials such as film, paper, etc.

3) Evenly distribute the pressure. The bending design of the banana roller effectively distributes the pressure and avoids uneven pressure on the material. Therefore, the lamination process also uses banana bending rollers.

The specific applications of banana rollers in the fields of printing, papermaking and textiles are as follows:

1) Paper and film production. In the production of paper and film, banana rollers are often used to adjust the material tension to ensure a smooth transfer of material and prevent breakage or wrinkles.

2) Textile industry. In textile production lines, banana rollers are used to help guide the fabric smoothly.

3) Printing industry: During the printing process, banana rollers help to eliminate curls and wrinkles of the material and provide accurate guidance.

Compared with other shapes of rollers, banana bending rollers have the following two advantages:

1) Make the movement trajectory of the material more accurate, and achieve higher machining accuracy and production efficiency.

2) Through special surface treatment, the surface of the banana roller has good friction resistance, corrosion resistance, and longer service life.

The material and specifications of banana rollers can be customized according to specific needs, and the following elements are generally required for customized banana bending rollers:

1) Material: According to different requirements for friction resistance and high temperature resistance, the materials of banana rollers usually include rubber, silicone, polyurethane, etc.

2) Specifications: In terms of specifications, the length, diameter, curvature and other parameters of the banana roller should generally be considered.

3) Radian: According to the user's needs, see whether the arc of the banana bending roller needs to be flexibly adjusted. Some materials have extremely demanding requirements for arc height. Generally speaking, the arc height should not be too large, and the material will be expanded due to force after the bending part, and some deformations are irreversible. However, if the arc height is not high enough, the force generated is not enough to unfold the material, especially if the edge of the material is not flattened well. In general, we recommend an arc height of 0.6%-0.9% of the width of the roll surface, and the standard arc of a curved roll is 1% to 1.4% of the standard diameter.

Contact factory in Guangdong, China

(Over 20 years experience in all kinds of rollers production )

Previous: China's Carbon Fiber Production Capacity Helps The Application Of Carbon Fiber Rollers

Next: How Does A Banana Roller Work To Flatten Out (paper, Film, Metal Plates Etc)?