Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

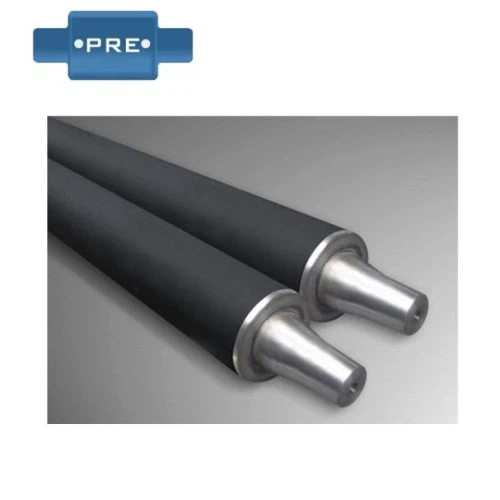

The carbon fiber roller is produced and processed from the carbon fiber tube, mainly carbon fiber material, the performance characteristics of carbon fiber material is light weight and high strength, which makes the quality of carbon fiber roller very light, and the load requirements for the parts of the equipment are also lower, which improves the service life of the equipment. In addition, the lighter carbon fiber rollers are easier to use, more convenient, and have a great improvement in productivity. Therefore, the combination will reduce the cost of carbon fiber rollers and reduce the production cost of products.

Advantages of carbon fiber shafts in industrial production processes:

1) High strength: Carbon fiber is a high-strength material with excellent strength, which makes the dynamic balance effect of carbon fiber roller better. This is suitable for carbon fiber rollers in the application, under high-intensity operation, can also have a good running effect, and the quality is also guaranteed.

2) High stiffness: the carbon fiber roller also has very strong bending performance, under the same product structure, the deformation of the carbon fiber roller with lower weight is also smaller, which can reduce the deflection and bounce in operation, and ensure the stability of the drum during high-speed operation. From the torsional strength analysis, the longitudinal tensile strength of carbon fiber composite materials is 20 times of the transverse tensile strength, and the longitudinal elastic modulus is 14 times of the transverse elastic modulus. Carbon fiber propeller shafts can withstand higher torque than ordinary propeller shafts,

3) Corrosion resistance: The surface of the carbon fiber roller has very good corrosion resistance, which can greatly improve the service life of the carbon fiber roller. Mainly from the analysis of material structure, the fatigue life of the shaft carbon fiber composite material is mainly composed of carbon fiber tow and resin material, the chemical properties of carbon are stable, no need for surface anti-corrosion treatment, its weather resistance and aging resistance are excellent, and the life is generally 2-3 times that of steel.

4) Wear resistance: Carbon fiber rollers are more resistant to friction than metal rollers, with less damage, which can reduce the frequency of maintenance.

5) Anti-fatigue: The carbon fiber drum has a smaller fatigue tendency, longer service life, and fewer replacements, which improves the overall reliability and stability of the equipment.

6) Flexible design: the production and processing performance of carbon fiber rollers is good, and the processing and production can be completed according to the corresponding size; A wide range of stiffness and strength can be manufactured to meet different application needs.

Problems and solutions in the use of carbon fiber shafts:

1) Brittleness and easy cracking:

Reason: Although carbon fiber reinforced composites have high strength, they are prone to crack formation under mechanical load.

Solution: Tougheners were added to the resin or interlaminated with nanofiber membranes to enhance impact resistance, fracture toughness, and delamination strength.

2) Not resistant to high temperature and wear:

Reason: Carbon fiber composites may degrade in high temperature and wear environments.

Solution: Thermoplastic resins or surface treatments to improve their resistance to high temperatures and abrasion.

3) Short service life:

Reason: The service life of carbon fiber drums may be shortened due to factors such as material quality, processing technology, usage scenarios, and maintenance conditions.

Solution: Select high-quality materials and precise processing technology, operate in strict accordance with the use specifications, and carry out regular maintenance.

4) Poor processing technology:

Reason: Failure to pass the processing process may lead to uneven distribution of roller performance and defects.

Solution: Improve the machining process to ensure uniform performance of the rollers and reduce defects.

5) Improper Maintenance:

Cause: Lack of regular maintenance can lead to degraded drum performance.

Solution: Develop and strictly follow a maintenance schedule, clean and lubricate the drum regularly, and prevent the accumulation of dust and foreign objects.

6) Man-made sabotage:

Cause: impact and damage caused by human factors during use.

Solution: Strengthen operator training, improve safety awareness, and avoid vandalism.

Application areas of carbon fiber rollers:

In the aviation field, the lightweight and high-strength characteristics of carbon fiber drive rollers help to improve the performance of aircraft; In the automotive industry, the application of carbon fiber drive rollers helps to improve the fuel economy and driving stability of automobiles; In the field of high-speed trains, the wear resistance and shock absorption effect of carbon fiber transmission rollers help to improve the operation efficiency and riding comfort of trains. In industrial production, the application of carbon fiber drive rollers helps to improve production efficiency, reduce energy consumption and reduce maintenance costs, and is widely used in various transmission and conveying systems and sorting and conveying equipment such as film production equipment, digital printers, mining conveying equipment, papermaking, printing, packaging machinery, lithium battery production equipment, etc.

Contact factory in Guangdong, China

(Over 20 years experience in all kinds of rollers production )

Previous: What Is The Function Of The Embossing Roller

Next: China's Carbon Fiber Production Capacity Helps The Application Of Carbon Fiber Rollers