Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Have you ever observed a tissue in your hand? Some toilet paper has two shallow indentations on both sides, handkerchief paper has delicate lines or brand logos on the four sides, and some toilet paper is fully embossed with uneven surface.

The effect of embossing on paper towels

1) Enhance cleaning power

The main function of paper towels is cleaning, which requires paper towels to have a certain degree of water absorption and friction, especially kitchen paper. Therefore, compared with pumping paper and rolling paper, embossing is more common in kitchen paper.

Paper towels are often made up of two or three layers of paper pressed together, and when embossed, the previously flat surface becomes uneven, creating multiple small grooves that better absorb and store moisture. The embossed tissue has a rougher surface, which can increase friction and adhesion. The embossed paper towel also has a larger surface contact area, which is better able to absorb dust and grease.

2) Make the paper firmer

Paper towels without embossing are easy to delaminate and easy to produce more paper scraps when used, and the embossing design solves this problem well. By vigorously squeezing the surface of the paper towel, it forms a structure similar to a mortise and tenon joint, and the concave and convex surfaces are nested with each other, which can make the paper towel more compact and not easy to loosen, and it is not easy to break when exposed to water.

3) Increase the fluffiness of the paper

Embossing can also allow air to collect in places that are not pressed, forming small bubbles, increasing the fluffiness of the paper and making the paper softer and more comfortable to the touch. When the paper absorbs water, embossing also locks in moisture and is more comfortable to use.

How do you emboss a paper towel?

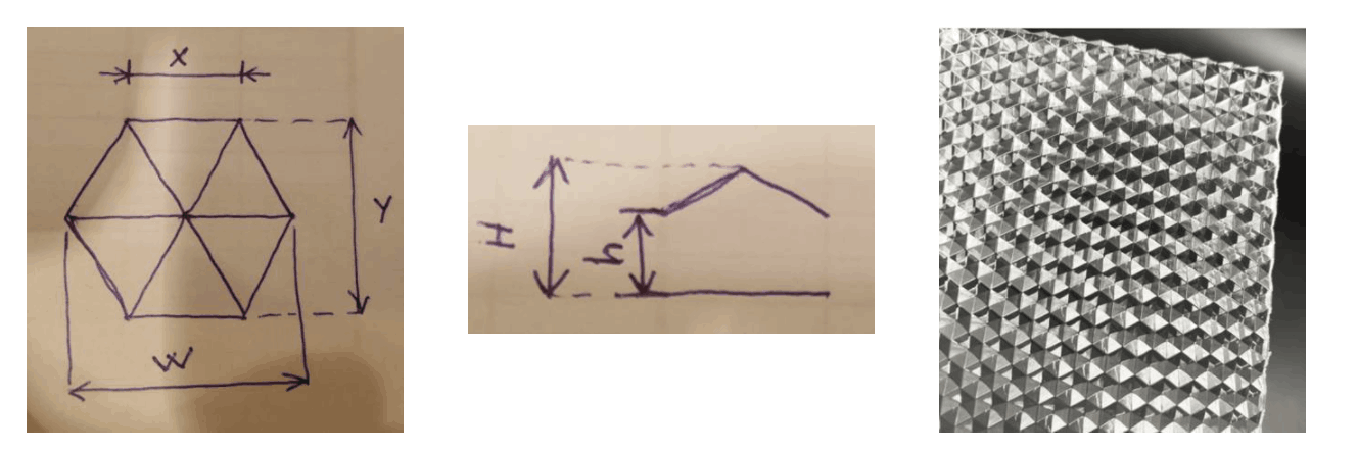

Paper towel embossing uses embossing rollers. Put the flat paper on the embossing roller, and squeeze the surface of the paper vigorously, and the pattern on the embossing roller is pressed on the paper. Nowadays, the common paper towels are made up of multiple layers of paper stacked together. When embossing, a small amount of glue is brushed to make the multi-layer paper more adhesive.

The embossing process of paper towels is similar to the embossing process of metal engraving. This process is very common in industrial manufacturing, for example, the round badge on the student ID card is vigorously pressed out with a steel stamp; In order to enhance the visual effect of the print, some prints will also use the embossing process on the cover; There are also packaging cartons, trademark labels, invitations, greeting cards, etc.

In a toilet paper rewinder, the rollers play different roles in the following different positions.

1) Pressing roller. The paper rollers in a tissue rewinder are primarily used to pressurize toilet paper, which is usually in the initial stages when the rewinder starts running. As the diameter of the toilet paper rewinding increases, the position of the press roller increases, and the load it provides gradually decreases. The pressure control of the paper roller needs to be selected according to the toilet paper material and the diameter of the toilet paper roll.

2) Support rollers. The function of the support roller is mainly to support the toilet paper and ensure the smoothness of the rewinding process. The speed at which the support rollers of the toilet paper rewinder rotate in conjunction with other rollers to form power. The size of this power determines the tightness of the toilet paper roll, the greater the power, the higher the tightness of the toilet paper roll, and vice versa.

As shown in the picture, the roller for the rewinder made of Shaoxing Futian roller

3) Conveyor rollers. The conveyor roller in the rewinder conveys the toilet paper to the rewinding roller, and the conveyor roller can also adjust the conveying situation of the toilet paper by controlling the rotation speed, so as to avoid the toilet paper conveying too fast or too slow to affect the rewinding effect.

4) Paper roll roll. As the core component in the rewinder, the paper roll is mainly used to rewind toilet paper rolls into finished paper rolls. Since the rolls usually need to rotate at high speeds, the rolls are dynamically balanced to ensure reliability.

To sum up, the application of rollers in the toilet paper rewinder is very wide, with the characteristics of automation and high efficiency. In addition, rollers can also be used in logistics conveyor lines, textile printing and dyeing equipment, printers and other fields.

In addition to the paper industry, rollers are also used in the following other fields:

1) Plastic industry: artificial leather, PU leather, all kinds of plastics (film, plate, sheet), plastic carpet, car interior carpet, placemat, bronzing hollow tablecloth, advertising light box cloth, Oxford cloth composite and all kinds of conveyor belts, etc.

2) Rubber industry: rubber carpets, shoe sole patterns and various industrial transmissions, etc.

3) Non-woven fabric industry: all kinds of flower-shaped hot-rolled non-woven fabrics

4) Textile industry: embossing on various textile materials, interlining sizing, interlining composite

5) Building hardware industry: building decorative panels, anti-skid aluminum panels, stained glass, wood-plastic panels, door sleeves and embossing on stainless steel decorative pattern boards, etc.

Contact factory in Guangdong, China

(Over 20 years experience in rollers production )