Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Significance of the emergence of the guiding system:

In the production process, roll materials such as paper, film, non-woven fabrics, sheets and other long-size continuous materials, in the process of their processing, need to go through unwinding, process treatment, winding and other work, due to the coil itself or equipment and other reasons lead to material deviation, resulting in material waste, production quality and efficiency decline, need to be corrected in real time. In order to reduce this phenomenon, the deviation correction system is a device that automatically corrects deviations without human assistance.

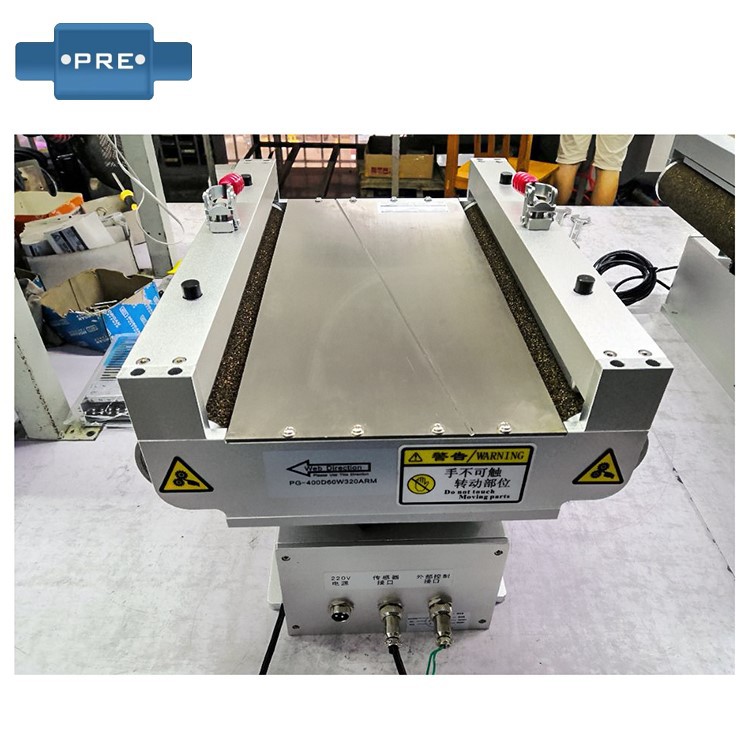

Advantages of servo correction all-in-one machine:

The servo guiding machine is used for precise guiding of narrow web materials, especially in the label printing, packaging and nonwovens industries. The all-in-one machine has a compact design, easy installation, saves equipment space, and integrates the controller, driver and detector, making installation and debugging more efficient.

The function of the paper splice table of the unwind guiding machine:

The splicing table of the correction machine will be installed in the correction machine, which is used for the coil to play the role of automatic splicing when the work stops, and it will be more convenient when the machine is stopped to change the material, and the material can be fixed, without re-wearing the material, which is convenient for changing the roll and splicing.

The difference between pneumatic and manual splicing table of servo guiding machine;

The main difference between manual and pneumatic with splicing station is the mode of operation. Manual splice splice stations are manually operated, while pneumatic splice splice splice stations are operated by pneumatics, which are often used in production environments where speed is required or where greater efficiency and precision are required.

The splice table is divided into manual splice table and automatic splice table:

1) The manual splicing machine is a relatively primitive splicing equipment, using a crane to install the web, the paper tape can be pulled out on the web, the paper tape can be threaded manually by hand, the printing equipment should stop working when changing the paper, remove the original web paper and replace it with a new web, manually connect the new paper tape to the old paper tape, and then reopen the machine, the process of replacing the web paper is inefficient, and it can no longer meet the current equipment production.

2) The double paper holder used by the automatic splicing machine can be equipped with two rotating arms, can directly load the paper from the ground, has its own lifting and correction mechanism, and has a paper storage rack, when the web is about to run out, the working machine can maintain the original speed without stopping the operation, but at this time the paper in the paper holder of the splicer is used, and the paper splicer can complete the automatic cutting and pasting during this time, so as to realize non-stop paper splicing.

There are two main functions of the automatic paper splicer:

a. In the normal working process, as an ordinary paper feeder to the working machine for paper supply;

b. When the original web in the working area is about to run out, the new web at zero speed (relatively stationary) in the splicing area is docked with the web in use, so that it can replace the original web to the working machine for uninterrupted paper supply, and the automatic splicing mechanism realizes the automatic exchange and continuous supply of the web, ensuring the efficiency and stability of carton production.

Functions and characteristics of the all-in-one edge guiding system:

1) Support photoelectric sensor, ultrasonic sensor, CCD sensor, support centering, edge chasing and line tracing working mode;

2) Automatic stroke detection, no need for mechanical limit switches, and can intelligently detect sensor parameters, in general, no need to calibrate the sensor;

3) Adopt variable PI adjustment algorithm without overshoot integral, which has a sensitive response and ultra-fast response speed (more than 0.5 milliseconds), high accuracy and small error;

4) Using differential filter, FIR digital filter, the signal is more stable and the anti-interference performance is better;

5) Analog sensor signal: 12-bit AD sampling up to 700,000 times per second, sampling speed;

6) User-friendly operation is fast and simple, with Chinese Simplified, Chinese Traditional and English 3 language menu operation;

7) Store 10 sets of different material parameters, switch materials conveniently and quickly, and support all system status parameters power-off memory;

8) DC servo motor pushes the ball screw and supports Modbus bus and PLC/HMI network control.

Contact factory in Guangdong, China

(Over 20 years experience in web guide system production )

Previous: What Factors Need To Be Considered When Choosing The Right Correction All-in-one Machine

Next: Choose 1000mm Or 1200mm Width Web Guide System,one Sensor Or Two Sensor