Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

The global competitive landscape is undergoing drastic changes, and in recent years, China has become the world's largest consumer and producer of carbon fiber. From 2019 to 2023, it is the outbreak period of China's carbon fiber production capacity, with nearly five times the production capacity in five years, and China's carbon fiber production capacity will account for 45% of the global market in 2025, according to Lucintel, a professional market analysis agency in the United States, China will account for more than 65% of the global production capacity by 2030, further helping China's carbon fiber cost to gradually decline. Carbon fiber prices have been a major obstacle to the adoption of carbon fiber in industry and other sectors where prices are expected at $4-$6/lb per unit, and some Chinese suppliers plan to sell carbon fiber in this price range, allowing them to take advantage of low carbon fiber costs to expand their market share. In addition to price pressure, there are still certain challenges in the recycling and sustainability of carbon fiber, carbon fiber rollers with the performance advantages of raw materials and high manufacturing level, can show high strength, light weight, long life, low noise, corrosion resistance, frictionless, maintenance-free, low energy consumption, optimized system layout and other advantages, become the preferred choice of more precision equipment, carbon fiber will still be a key part of the future development of industry, transportation, aerospace and other fields.

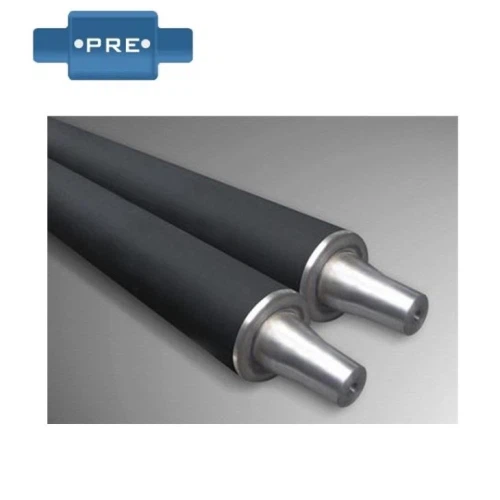

Carbon fiber rollers are a typical form of carbon fiber composite materials used in the industrial field. The carbon fiber roller is mainly made of carbon fiber composite prepreg as raw material and specific metal parts, and the whole process is as many as a dozen links from layup rolling to finished product testing. Carbon fiber is 30% lighter than aluminum, the fatigue life is more than 2 times that of aluminum alloy, the rigidity is increased by about 3 times, and its tensile strength can reach more than 3000MPa, which is more than 6 times that of steel. At present, in many industries such as printing, papermaking, non-woven fabrics, textiles, lithium battery manufacturing, etc., the related equipment of these industries needs to use a large number of rollers and roller parts.

In roller applications, carbon fiber composite rollers show significant lightweight advantages. Compared with traditional metal rollers, carbon fiber rollers have the following significant characteristics:

1) Light weight: The density of carbon fiber composite materials is much lower than that of metal materials, which can effectively reduce the weight of the whole equipment.

2) High stiffness: The high modulus of carbon fiber composite materials ensures the rigidity of the roller body during work and reduces the deflection deformation.

3) Good balance: Uniform material distribution and precise manufacturing process ensure the dynamic balance of the roller body and reduce the vibration.

4) Small inertia: low moment of inertia helps to improve the acceleration response speed and save energy consumption.

5) Long service life: Excellent wear resistance and corrosion resistance prolong the service life of the equipment.

6) Low noise: The sound absorption effect of carbon fiber material is good, which can reduce the noise generated during operation.

7) Wear resistance: The surface hardness is high, not easy to wear, and the stability of long-term use is maintained.

The production and processing technology of carbon fiber rollers is roughly divided into the following three steps:

1) The production of blanks

Carbon fiber rollers are usually made of carbon fiber pipes made by winding and forming process. The carbon fiber winding molding process is to wind the continuous fiber (or cloth tape and prepreg yarn) soaked in resin glue to the core mold according to a certain rule, and then cure and demould to obtain the product. According to the physical and chemical state of the resin matrix during filament winding, it can be divided into three types: dry winding, wet winding, and semi-dry winding.

2) Handling of outer circle and cross-section

The processing of the outer circle and section of the carbon fiber roller is extremely detailed in the program, including rough turning, semi-finishing turning, fine turning, rough grinding, fine grinding, grinding, superfinishing, fine turning, etc., and the indicators achieved by each program in economic accuracy and surface roughness are different. The following summarizes the machining of the outer circle and section of the carbon fiber roller into three stages: roughing stage, semi-finishing stage, and finishing stage.

3) Surface treatment

The most common surface treatment method of carbon fiber rollers is painting, and the painting link should be constantly interspersed in the above-mentioned rough and finishing procedures, which will generally be carried out in the order of painting (the first pass), coarse grinding, painting (the second pass), coarse grinding, fine turning, and fine grinding.

Contact factory in Guangdong, China