Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Web guiding system refers to the manufacturer of the coil in the process of spraying, printing, punching, lamination, slitting or other coil winding, always to keep the side of the coil neat and consistent and take the technical operation of its wide use to the industry has brought great benefits, correction control in corrugated, textile, printing, labeling, labeling, papermaking, plastic film and other processing industries are widely used and play a great role.

Principle of the correction system: The guiding sensor B emits infrared light/ultrasonic/laser/visible light to monitor the operation of the coil, and sends the signal to the controller A. After the controller finds that the coil has position drift, according to the instruction preset by the controller, the correction frame C swings by the driver D, and the coil position is corrected. The automatic deviation correction system of the coil uses a photoelectric sensor to detect the position of the edge of the coil, and sends the measured position error signal to the controller, and after the control unit judges and processes, the drive motor is controlled to correct the coil with the deviation position to the correct position. The FIFE guiding system offers several different inspection methods: edge detection, wire following or alignment. Its drive system is driven by low-speed synchronization, frequency conversion speed regulation, stepper and servo motors, and the drive stroke is strictly proportional to the coil offset. The system can also be used with different probes to meet the needs of detecting different coils, such as: infrared photoelectric, analog infrared photoelectric, etc. The microcomputer digital controller provides precise control of the various functions of the system.

In the process of purchasing a corrector for our customers, there are usually two problems:

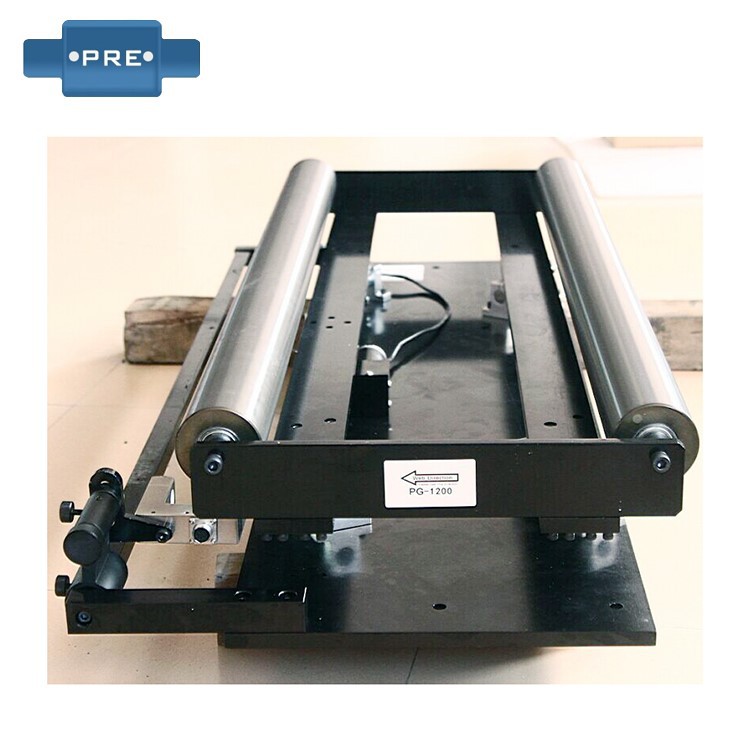

Question1: What width trainer to choose, such as 1000mm or 1200mm width?

Anwser: What width to choose is also based on the width of the material. Here's an example of a customer request email:

Customer: Furthermore, I initially messaged regarding the 1200mm web guide because it is the only size above 1000mm I saw on your website, I was actually looking for 1000mm web guide, is this something you also have?

PRE Factory(web guide system manufacturer in china):Surely 1000mm web guides is available,pls find attached sketch.

Question2: Is it better to have 1 or 2 sensors at the same time?

Anwser: If equipped with 1 sensor, it can switch between two working modes of "single side correction" and "contrast correction", and the order side correction: according to the left or right edge of the material; Contrast correction: Correction is carried out according to the comparison of a continuous or discontinuous line.

If it is 2 sensors, then the working mode will be "tracking center (CPC)", which is based on the center line of the material for correction, and can be divided into fixed centering correction and mobile centering correction.

On slitting machines, plastic printing machines, rewinding machines and other machines, strip deviation is a very common phenomenon. The so-called strip deviation refers to the fact that flexible strips such as paper and plastic may be affected by uncontrollable forces during operation, and cannot maintain straight line operation and make the center line of its width deviate from the center line of the datum. The strip generally goes through three links in the transmission, namely unwinding, passing through the intermediate transition roller, and winding. Due to the many links it goes through, there are many opportunities for the strip to deviate. There are many reasons for strip mistracking, such as the axis between the drive rollers is not parallel, the surface of the drive roller is not cylindrical, the surface processing defects and the strip tension is unstable. It is difficult to ensure that the strip deviation is within the required range through the machine itself, and it is usually used to automatically correct the deviation by adding an automatic deviation correction system.

Contact factory in Guangdong, China

(Over 20 years experience in paper web guide system production )