Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

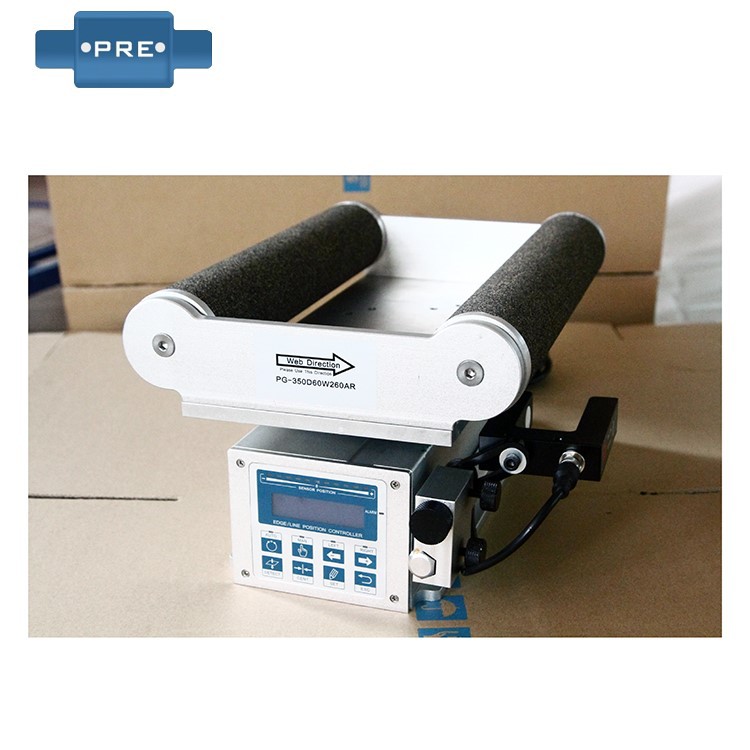

The correction device is a kind of tracking the edge or printed line of the working material for high-precision differential and oscillation, and the correction controller can be selected; It is composed of large-scale industrial integrated circuits, which has the advantages of strong anti-interference ability, high reliability and long service life in harsh working environment. To meet the needs of continuous non-stop production in the printing and packaging industry, it has been widely used in non-woven fabrics, plastic film slitting machines, special material slitting machines, coating machines, printing machines, laminating machines and other equipment.

Composition and working principle of the guiding system:

The deviation correction system is a basic component of the closed-loop control system, controller, sensor, linear guide mechanism constitutes closed-loop control, first the deviation correction sensor detects the edge or line of the coil, reads the actual position of the coil and the offset of the set position, converts the offset into a proportional electrical signal, and then sends the electrical signal to the controller, the controller amplifies the signal, and outputs it to the linear driver after calibration, and the linear driver drives the deviation correction guide mechanism according to the size of the signal, and restores the coil to the set position. The drive signal of the current drive is only proportional to the coil deviation, allowing the guiding system to provide accurate control for a wide range of different coils.

Web guide system features:

1) Automatic speed change, which can automatically adjust the speed with the error size of the material parts, and the stability is better.

2) Infrared high-sensitivity photoelectric eye, accuracy 0.05mm. It can distinguish 2 layers of film, and can also do special border inspection.

3) Any material such as paper, cloth, rubber and plastic, fine mesh, metal... All can be detected and controlled.

4) Any color such as dark black, mirror reflective, transparent film... and other volumes can be easily detected and detected.

5) DC servo-electric type, large thrust and fast response.

6) It can be used to make a special opposite edge on the inner edge of the roll (generally only the outer edge can be corrected).

Choose the appropriate guiding mode according to the degree of material processing:

The guiding mode of the guiding system depends on the degree to which the material is processed. Unprocessed materials can only be guided according to the edge centerline of the material, as these materials have no other comparative properties to refer to. The processed material has more properties when guiding, such as printed lines or contrasting edges. Enables analog or digital guide sensors to scan the position of the material.

a. Material order correction

Depending on the left and right edges of the material, edge guiding sensors are used for guidance.

b. Material centerline correction

Depending on the centerline of the material, two edge guiding sensors are used for guidance.

c. Contrast correction

According to a continuous or discontinuous printing line or opposite.

Web guiding systems are widely used in coil production line equipment:

It is widely used in papermaking machinery, packaging machinery, conveying machinery, printing machinery, film production equipment, chemical equipment and other fields. The web trainer on the coil production line is used to correct the coil in the process of spraying, printing, punching, laminating, slitting or other coil winding to keep the coil side neat and consistent.

Preparation and precautions before the start of the web guiding system:

1) Check whether the mechanical seal, as well as the installation of accessories and pipelines are complete and meet the technical requirements.

2) Static pressure test is carried out before the mechanical seal is started to check whether the mechanical seal has leakage. If there is a lot of leakage, the cause should be investigated and eliminated. If it still doesn't work, you should disassemble it for inspection and reinstall it. Generally, the static pressure test pressure is 2~3 kg/cm².

3) The sensitivity adjustment of the correction system is a key step, which directly affects the correction effect and stability of the system. By gradually adjusting the sensitivity, continuously optimizing the system settings, and testing and verification according to the actual needs, the best detection and correction results can be obtained. In the adjustment process, it is necessary to pay attention to the system stability, false alarm risk and real-time requirements to ensure that the system can meet the needs of the production line.

The guiding system works in cooperation with the tension controller and brake:

The trainer and tension control system can detect the running position and tightness of the paper web in real time, and adjust the braking force of the base paper brake (now equipped with multi-point brake) according to the change, forming a control loop of "detection→ feedback → braking", so that the paper web always maintains the appropriate tension and the correct position on the whole tile line, so that it meets the production requirements of higher speed, and the door width of the whole line is quickly aligned to achieve trimming integration.

The guiding process of the web guiding system on the coil production line equipment:

1) Unwinding and rectifying:

Make sure that the web is always exported from the set position during the unwinding process. Design and installation rules: the export roller and the unwinding moving frame are integrated, and the sensor is installed behind the export roller and fixed separately, close to the position of the export roller.

2) Process Correction:

Ensure that the coil in the process always passes through the set position. Design and installation rules: The sensor is installed between the guide mechanism between the export roller and the pressure roller, which is fixed separately and is close to the position of the export roller.

3) Winding and rectifying:

Make sure that the coil edges are neat when rewinding.