Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

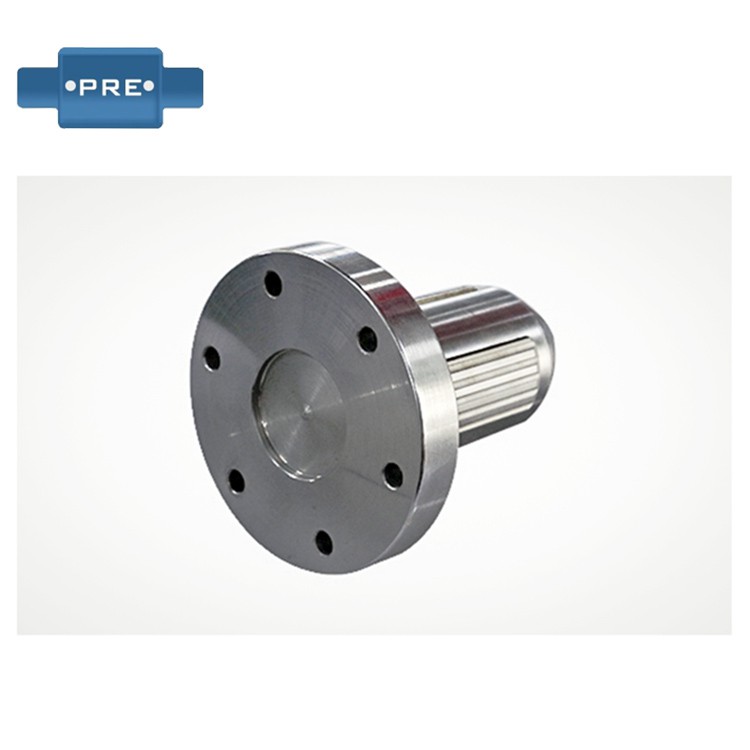

The pneumatic air shaft chuck is a new type of clamp, its working principle is to use gas pressure to make the chuck shrink and open, when the gas path is filled with gas, the chuck will shrink and clamp the working piece; When the gas is discharged, the chuck opens.

This kind of fixture has the advantages of high precision, fast speed and strong reliability, and is widely used in various precision machining occasions.

The inflatable core chuck is mainly composed of the chuck body, clamping air path, leakage gas path and other parts.

The inflatable chuck not only has the function of automatic centering, but also can replace the ordinary inflatable shaft, when the center positioning of the shaft is required, the inflatable chuck is the ideal solution, in addition, the inflatable chuck has a wide range of applications, can be used in the coil winding and unwinding equipment and assembly line.

The role of using an inflatable safety chuck in production machinery:

1) Improve production efficiency

Quick connection and separation: The inflatable chuck can quickly clamp and release the packaging material, which greatly saves the time of loading and unloading compared with the traditional manual or mechanical chuck. This quick connection and separation allows the packaging machine to change materials faster during the production process, reducing downtime and thus improving overall production efficiency.

High degree of automation: In automated packaging production lines, inflatable chucks are usually combined with sensors, control systems, etc. to achieve automatic operation. This further increases the degree of automation of the production line, reduces manual intervention, and improves production efficiency and stability.

2) Ensure the quality of production

High-precision clamping: The inflatable chuck is clamped by gas pressure, which has high precision and stability. In the packaging process, it can ensure that the packaging materials are evenly and firmly clamped, and avoid the problems of loose packaging and damage caused by poor clamping, so as to ensure the production quality.

Strong adaptability: the inflatable chuck usually has a variety of specifications and models, which can adapt to different sizes and shapes of packaging materials, which makes the packaging machinery flexible in the production process to cope with various packaging needs, and improves the flexibility and diversity of the production line.

3) Reduce production costs

Reduce labor input: The automatic operation of the inflatable chuck reduces the need for manual intervention, reduces labor costs and labor intensity, and at the same time, reduces the production loss caused by human factors due to the reduction of errors and negligence in manual operation.

Extend equipment life: The inflatable chuck has a stable structure, is not easy to damage, and has a long service life, which reduces the cost of equipment repair and replacement, and also reduces the downtime caused by equipment failure, further reducing production costs.

4) Improve security

High safety performance: The inflatable chuck is fully considered in the design and use of safety performance. For example, the clamping and unclamping operation is achieved by means of gas pressure, which avoids the risk of mechanical injury that can be associated with traditional mechanical chucks; At the same time, some advanced inflatable chucks are also equipped with safety protection devices, which can automatically stop or alarm in abnormal situations, further improving production safety.

Classification of inflatable chucks:

Rubber inflatable chuck: This kind of chuck is made of rubber material, which has excellent elasticity and wear resistance, and is suitable for clamping work with high precision requirements, and the softness of rubber makes the chuck better adapt to different shapes and sizes of workpieces to achieve tight clamping.

Aluminum alloy inflatable chuck: Aluminum alloy inflatable chuck is favored for its light weight and excellent mechanical properties, it has high strength and hardness, while maintaining a certain toughness, suitable for occasions with high requirements for clamping force.

Nylon inflatable chuck: Nylon inflatable chuck has good wear and corrosion resistance, which can maintain stable performance in harsh working environments, in addition, nylon material also has certain self-lubrication, which helps to reduce friction and wear during clamping.

Features of inflatable chucks:

1) Quick clamping: The inflatable chuck can expand and contract quickly, which is convenient and fast to clamp and release the workpiece.

2) High precision: The inflatable chuck usually adopts a high-precision manufacturing process, which has high positioning accuracy and repeated positioning accuracy, which can ensure the machining accuracy of the workpiece.

3) Suitable for workpieces of various shapes: the inflatable chuck can be applied to workpieces of various shapes, such as round, square, flat, etc., with good adaptability.

4) Easy to adjust: The inflatable chuck can be adjusted according to the size and shape of the workpiece to fit the workpiece of different sizes and shapes.

5) Easy to clean: The inflatable chuck has a simple structure, easy to disassemble and clean, and is convenient for care and maintenance.

When using an inflatable chuck, you need to pay attention to the following:

Choose the right clamp and tubing: Choose the right clamp and tubing for your specific needs to ensure that the chuck can grip the workpiece firmly and prevent the workpiece from moving or falling off during machining.

Replace damaged parts in a timely manner: The clamping block and the tubing may be worn or damaged during the use of the inflatable chuck. In order to ensure the stability and safety of the chuck, these damaged parts should be checked regularly and replaced in time.

Pay attention to the operation specifications: when using the inflatable chuck, the operation specifications should be strictly adhered to to avoid the loss of control of the fixture due to misoperation, resulting in danger, and the operator should be familiar with the working principle and correct use of the inflatable chuck to ensure safe use.

Check chuck integrity: Before using an inflatable chuck, the chuck should be carefully inspected for defects such as cracks, deformation, etc. As soon as these problems are discovered, the chuck should be replaced immediately to ensure the safety and stability of the machining process.

Regular care and maintenance: In order to prolong the service life of the inflatable chuck, regular care and maintenance are required, which includes cleaning the chuck, checking the wear of the components, and replacing the severely worn parts in time.

When choosing an inflatable chuck, there are several factors to consider:

Workpiece material and size: the first thing to consider is the material and size of the workpiece to be clamped, different materials and sizes of workpieces need different types and specifications of inflatable chucks, generally speaking, the larger the workpiece, the harder the material, you need to choose an inflatable chuck with greater clamping force.

Clamping accuracy and stability: Clamping accuracy and stability are important factors to consider when choosing an inflatable chuck, the higher the clamping accuracy and stability, the better the quality of the processed products, therefore, it is necessary to choose an inflatable chuck with appropriate accuracy and stability according to the processing requirements.

Environment and conditions of use: The environment and conditions of use of the inflatable chuck also need to be considered. For example, if the working environment temperature is high or the humidity is high, you need to choose an inflatable chuck with good temperature and humidity resistance, in addition, you need to consider the power, air pressure and other factors of the machine tool.

The manufacturer's years in the field of inflatable chuck production: The long-term accumulated experience in the production of inflatable chucks can effectively ensure the production quality of inflatable chucks.PRE factory has more than 20 years of experience in the production of inflatable chucks