Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

air expanable shaft inflatable air pressure range:

An core shaft is a device that works using the principle of air pressure to achieve its function by controlling the air pressure in the range of 6-8 kg. The inflatable shaft works by inflating the surface with high-pressure inflation to stabilize the reel core. When it is time to fix the reel core, simply align the inflation handle with the air valve on the inflatable shaft for inflationary operation. When it's time to loosen the reel, simply press the sliding core on the valve to deflate. The standard range of inflatable shaft inflation pressure is 0.04~0.05MPa, do not exceed this range, otherwise it will cause damage to the inflatable shaft.

air pneumatic shaft inflation method:

1) Manual Inflation:

How it works: The operator uses an inflatable handle or similar tool, aligns it with the nozzle on the inflatable shaft, and then fills the valve with high-pressure gas through manual operation. When it is necessary to deflate, press the sliding air core on the air nozzle by hand to expel the gas and retract the key bar or bump on the surface of the inflatable shaft. This method is simple and straightforward, and is suitable for some occasions where the filling frequency is not high, the equipment operation space is relatively large, and the inflation speed is not strict, such as small printing presses, some packaging machinery, etc.

2) Auto-inflat:

Working principle: The end face of the shaft head of the inflatable shaft is connected with a rotary joint, and the rotary joint is then connected with the automatic inflation device. An automatic inflating device usually consists of an air source (such as an air compressor), an air pressure control system (including a pressure sensor, a regulating valve, etc.), and an electrical control system. When the equipment sends out an inflation signal, the high-pressure gas provided by the air source enters the air bag of the inflatable shaft through the rotary joint to achieve inflation; When it is necessary to deflate, the electrical control system controls the air pressure control system so that the gas is discharged from the air bag.

Advantages: The automatic inflation method can achieve fast and accurate inflation and deflation operations, improve production efficiency and work stability, and is especially suitable for large-scale automatic production equipment with high requirements for inflation accuracy and frequency, such as high-speed slitting machines, large-scale coating machines, etc.

Steps for installation and use of inflatable shafts:

1) According to the type and size of the coil, select the corresponding inflatable shaft, place it in the center of the coil, and fix the two ends of the shaft on the coiling device.

2) The inflatable shaft should be installed on the coiling equipment and used in conjunction with the motor and control system.

3) Before use, the surface of the inflatable shaft should be cleaned for better adhesion to the coil.

4) Connect the air supply line and start inflating.

5) When the thickness of the coil changes, the air pressure needs to be adjusted to achieve the best tension and coil diameter.

The appropriate inflatable shaft material and structure can be selected according to the requirements:

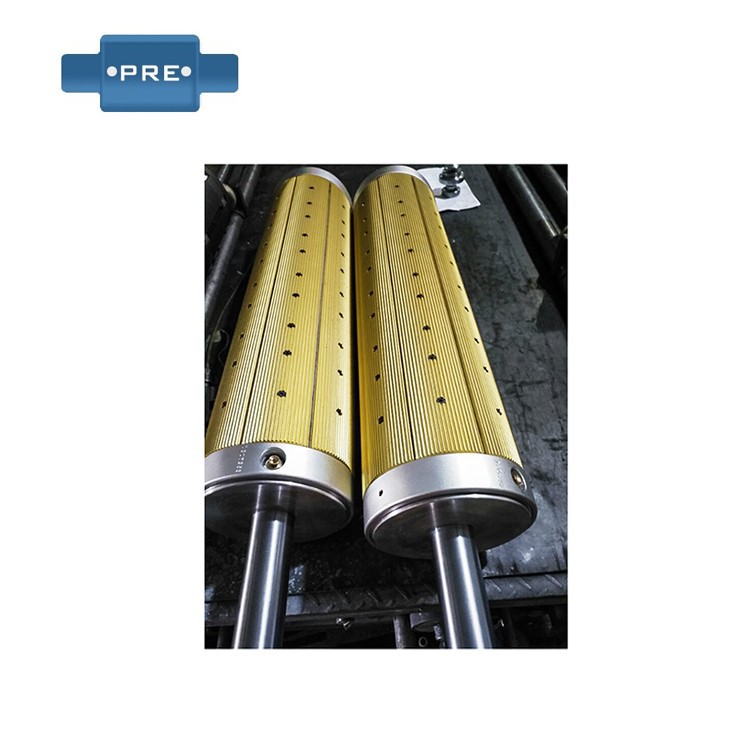

The basic structure of the inflatable shaft is basically composed of a cylinder, an inflatable key, a tubular airbag, an end shaft, an air intake core tube and an air intake joint. The cylinder is the main load-bearing structure of the air expansion shaft. The shape of the keyway is comparable to the contour line of the ordinary round-headed flat key, and its length is longer than that of the flat key. The keyway is distributed along the circumferential direction of the cylinder at 120°, 90°, 72°, 60°, etc., and is aligned or staggered in the axial direction. The end shaft is installed at both ends, and the simplified body and the end shaft are connected with countersunk screws, and in some structures, in order to prevent loosening or air leakage, the threads of the screws are coated with adhesive.

1) The key bar is made of composite rubber/polyammonia.

Key strip material and processing accuracy control:

a. The key strip is generally made of metal material, such as carbon steel or stainless steel. Stainless steel key strips (such as 304, 316 stainless steel) have good corrosion resistance and are suitable for some environments with high requirements for rust prevention, such as food packaging, electronic material processing and other fields.

b. The machining accuracy of the key bar directly affects the performance of the inflatable shaft. In the processing process, the dimensional accuracy of the key strip should be strictly controlled, including length, width, thickness and shape accuracy. For example, the width tolerance of the key bar should generally be controlled within ±0.05mm, the length tolerance should be controlled within ±0.1mm, and the surface roughness (Ra) should reach 1.6 - 3.2μm to ensure a tight fit between the key bar and the inner wall of the reel material.

2) The shaft body material is divided into: aluminum alloy, high-strength alloy steel.

The shaft material of the inflatable shaft should be selected according to the load requirements of the actual application scenario:

a. For inflatable shafts that bear greater tension and heavier drum materials, such as in industrial papermaking, plastic film winding and other fields, high-strength alloy steels are generally selected, such as 40Cr, 42CrMo, etc., which have high strength and toughness, and can withstand greater pressure and torque.

b. If it is used in occasions with low load requirements, such as some light printing rewinding or small packaging material processing, aluminum alloy materials (such as 6061, 7075 aluminum alloy) are a good choice, its advantages are light weight, easy to operate and install, and also have a certain strength.

3) Shaft head structure at both ends: customized processing according to the needs of different equipment, common flanges, optical shafts, key shafts, square heads, triangular heads, cone heads, internal tooth heads, etc.

4) Types of inflatable air nozzles: divided into two structures: sharp and flare, each size G1/4, G1/8, G1/16 specifications, each length has ordinary type, extended type.

5) Number distribution of inflatable nozzles: single nozzle/multi-valve can be selected, which are distributed in the outer circle of the shaft body/outer circle of the shaft head/the end face of the shaft head.

6) The inflatable shaft is a special winding and unwinding shaft, which can be convex after high-pressure inflation, and the surface part is quickly retracted after deflating. The inflatable shaft is inflated by high pressure, and the key strip on the surface of the shaft will protrude, which is used to jam the coil and realize the easy rewinding and release of the coil. There are 1 inch, 1.5 inch, 2 inch, 2.5 inch, 3 inch, 6 inch, 8 inch, 10 inch, 12 inch, etc., which can be processed and produced according to customer needs.

7) Airbag material selection and inspection: Airbag is a key component of the inflatable shaft, and its material is usually rubber or thermoplastic elastomer (TPE). For inflatable shafts used in high-temperature environments, such as the thermal winding process in the production process of some plastic films, it is necessary to choose high-temperature resistant rubber materials, such as fluoroelastomers, which can maintain good elasticity and sealing properties at higher temperatures. Before use, the airbag material should be strictly inspected for quality, including checking the elasticity, air tightness, aging resistance, etc. of the material. The quality of the airbag material can be ensured by sampling for tensile tests, air tightness tests, etc. For example, the air tightness test can determine whether the air tightness is good by inflating the air bag to a certain pressure and leaving it for a period of time to observe whether the pressure drops.