Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

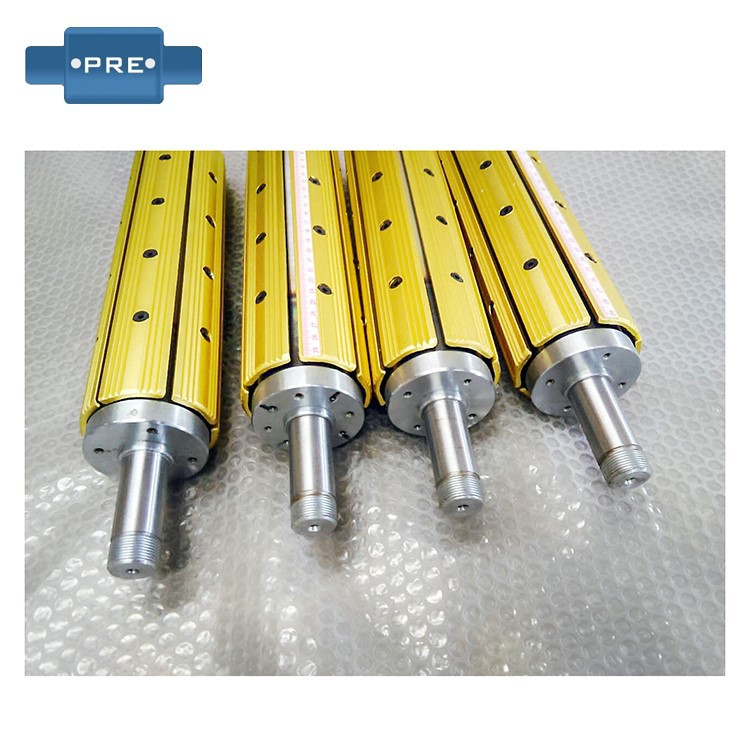

Plate air shaft is also called plate pneumatic shaft, slat inflatable shaft, six-piece core expanded shaft, tile inflatable shaft, etc., but the working principle is the same.

Structural characteristics of plate air shaft:

1) The expansion part of the plate air expansion shaft is a plate, usually the expansion height can reach 4mm to 5mm, such as the diameter before expansion is 74mm to 75mm, and the diameter after expansion can reach 78mm to 79m, special expansion height, separately requested, set by the customer.3 inch plate type air shaft, usually using the inner diameter of the coil tube is 76mm. The plate inflatable shaft expands the whole plate, the fulcrum is evenly dispersed, and the force is uniform, which can be applied to machinery with high winding precision or lighter winding items.

2) The plate inflatable shaft shaft body is divided into shaft body and plate, the shaft body is generally made of steel or aluminum, mainly for load-bearing, the plate material of the plate inflatable shaft is aluminum, the color of the plate is silver, brown and gold, of which silver belongs to the natural color of aluminum, and the general large-scale inflatable shaft, which refers to the working interval of more than 1.5 meters long, is made of this color.

The use of the tile type air shaft (slat air shaft): the tile type air shaft expands the whole plate, the fulcrum is evenly dispersed, and the force is uniform, which can be applied to machinery with high winding precision or lighter winding items, such as: electronic materials, battery materials, foam, plush, paper products, non-woven fabrics, etc. It is suitable for coating, slitting, printing, rewinding, laminating, papermaking, bag-making, plastic and other related machinery reeling and unwinding reels, especially suitable for paper tubes with high roundness requirements or the use of surface rewinding and unwinding occasions, which can effectively improve work efficiency and product quality.

The tile type air shaft (slatted air shaft) has the following 6 advantages:

1) Simple placement: Compared with the key inflatable shaft, the placement of the plate inflatable shaft does not use most of the rules, and it can move and fix any position of the paper core on the shaft surface in terms of inflation and deflation action.

2) Long use time, simple maintenance: tile type inflatable shaft (slatted inflatable shaft) is the longest durability of several inflatable shafts, and it is relatively easy to maintain: the inflatable shaft is a single part, and each part in its structure has fixed specifications, all of which can be interchangeable and convenient, making it easy to maintain.

3) Wide application: As an independently designed part, the inflatable shaft is from 1 inch --- 12 inches, the length and size are determined by the actual needs of customers, and it is suitable for branch pipes of various widths and heights, and the practicability is very high.

4) Large carrying capacity: The inflatable shaft can be designed according to the actual model, using high-quality steel to increase the carrying capacity. For example, steel can be used for weight of more than 1 ton, and the radius of the shaft can be flexibly determined according to the customer's needs.

5) The inflation time is short, and it only takes 2 seconds to complete the inflation and deflation action of separating and placing the coiled tube, which is simple and convenient to place the coiled tube, safe and applicable. All machinery and equipment for winding and unwinding can be applied to inflatable shafts. The length of the inflatable shaft can be six meters or more, and the short can be several hundred millimeters, all according to the customer's needs.

6) Single fitting: The inflatable shaft is a single spare part of the winding and unwinding machinery, and each part in its structure has a fixed specification size, which can be decomposed and combined, so that the maintenance is convenient and durable.

Tile type air shaft (slat air shaft) is mainly used in the following machinery:

Drying machine, flexo printing machine, gravure machine, trademark printing machine, coating machine, leather machine, setting machine, embossing machine, slitting machine, die-cutting machine, rewinding machine, paper tube machine, bag making machine, laminating machine, laminating machine, film blowing machine, foaming machine, laminating machine, embossing machine, paper machine, non-woven machine, cloth inspection machine, hot stamping machine, battery equipment and other related machinery and other related supporting use;

Problems to consider in the production of shingle-type inflatable shafts:

1) Whether the design of the inflatable shaft can take into account the assembly, disassembly and assembly of the inflatable shaft. The diameter of the tile inflatable shaft should be large in the middle and small at both ends, so as to facilitate the flexible disassembly and assembly of the components on the shaft. The end of the shaft and the transition between the journal and the shoulder should be chamfered or over-rounded, which is conducive to the assembly of the part on the shaft, can avoid abrasion of the mating surface, and can also better reduce the concentration of forces.

2) The purpose of the tile inflatable shaft (inflatable shaft) should be considered in the design. Can it be used in that industry? Do the designed features meet the needs of the user?

3) The strength of the inflatable shaft (inflatable shaft) mainly includes stiffness and fatigue strength. It is necessary to accurately check the strength of the inflatable shaft (inflatable shaft) fittings, and if they do not meet the requirements, they should be replaced in time.

4) In the production process, whether it can be conveniently processed with ordinary tools, the two keyways of the inflation shaft (gas expansion shaft) should be of the same width and on the same busbar, so that it can be processed better, because how to deal with the material has a great impact on the strength.

Ordering Guidelines:

When customizing the inflatable shaft, the user needs to specify the type of inflatable shaft, the external dimensions, the position of the air valve, and the tolerance of the important dimensions on the shaft head. If the air is inlet in the axial direction, the outer diameter of the axle head should be greater than 35mm when the valve is installed. All inflatable shafts need to be issued with formal drawings and confirmed by both parties before they can be produced.

Previous: The Range Of Expanded Air Pressure Of The Inflatable Shaft

Next: Why Is It Highly Recommended To Use A Multi Bladder Type Air Shaft?