Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

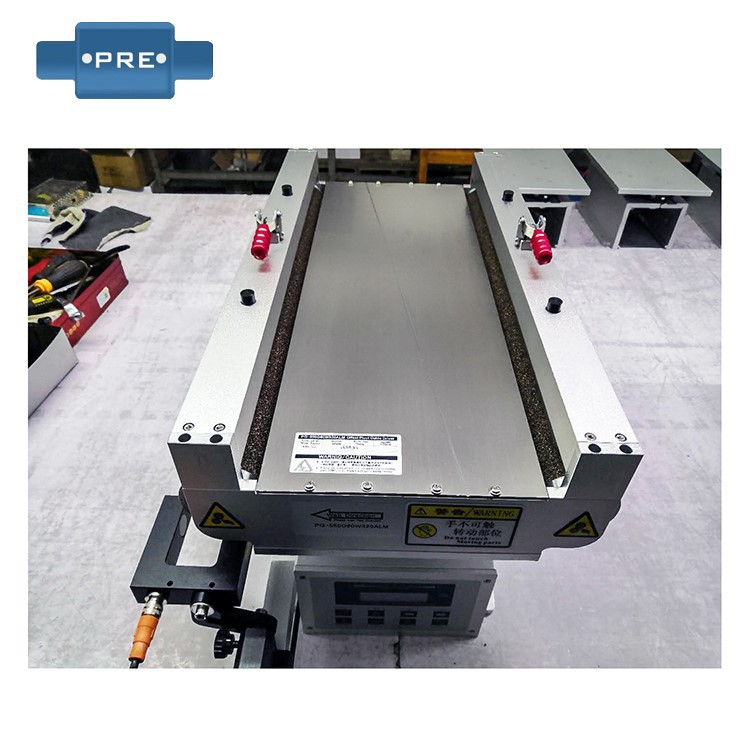

A web guiding system generally consists of three main components: a sensor, a drive, and a controller. Sensors are used to detect the exact location of the material; The driver is used to drive the mechanical structure and control the position of the material, and the control box is used to analyze and process the signals of the sensor and the driver. According to the material characteristics and requirements of the detection, the appropriate guiding sensor can be selected, and the appropriate driver can be selected according to the working linear speed and load.

Classification of guiding systems:

According to the different detection and control methods, the correction system can generally be divided into three types: EPC edge correction, LPC line correction, and CPC center correction. According to the actual situation of production, the system configuration of the EPC guiding system and the CPC centering device will not be exactly the same. The CPC alignment control system is to ensure that the steel belt is always kept in the center of the production line, so it has two position sensors, for example, in the centering system on the uncoiler, the position sensors are located at the two edge positions of the running steel belt, in order to meet the requirements of different width steel belt edge detection, a set of sensor moving device is installed. The purpose of the EPC guiding control system is to ensure that the edge of the belt reel is neat during winding, so it has a position sensor.

The choice of the guiding system mode depends on the customer's process requirements, and the main guiding modes are as follows:

Single-edge correction of film orders (EPC): using a sensor to guide according to the left or right edge of the film.

Film centerline correction (CPC centering correction): using two sensors, according to the centerline of the material for correction, it can be divided into fixed centering correction and mobile centering correction.

Thin Film Contrast Guiding (LPC Line Guidance): Using a single sensor, the guiding is based on a continuous or discontinuous line comparison.

How the web guiding system works:

The working principle of the coil correction system is to detect the edge or line of the coil through the sensor, the system automatically reads out the offset of the actual position of the coil and the set position, and converts the offset into an electrical signal and transmits it to the controller, the signal is amplified and calibrated by the controller, and then output to the linear driver, and the linear driver drives the deviation correction and correction mechanism according to the size of the signal, and restores the coil to the set position.

Functions and features of the guiding system:

1) Support three working modes: chasing line, chasing edge, and pairing.

2) Support photoelectric sensor, ultrasonic sensor, CCD sensor.

3) Intelligent detection of sensor parameters, no need to calibrate the sensor in most environments.

4) Automatic stroke measurement, no need for mechanical limit switch.

5) Variable PI adjustment algorithm without overshoot integral, high precision, quick response and smaller error.

Why install a web guiding system:

The web correction system has the automatic processing process of high-speed, high-precision and high-efficiency coils, and the control requirements for the transverse position of coils are getting higher and higher. Equipped with high-performance automatic web guiding is the key to increasing the production capacity and yield of coil materials. The coil will have lateral displacement (deviation) in the process of unwinding, middle section and receiving, so the correction system can be installed at the above three positions as needed to control the coil to pass through the corresponding position accurately.

Which industries and machines are the guiding systems used in?

Industry: The deviation correction system is widely used in film printing and packaging, papermaking, textile, rubber, steel and other industrial machinery, which can increase efficiency, improve quality, reduce consumption and reduce manpower.

Machine: The guiding device is a new type of guiding system for light industrial automation. It is suitable for various occasions that need to be controlled by transverse correction of strip materials, and can be matched with slitting machines, bag making machines, laminating machines, coating machines, paper machines, printing machines, textile and building materials machinery that need to be controlled by guiding deviations.

The debugging and testing of the deviation correction system is as follows:

1) Check and connect: Make sure that the guiding system has been properly installed and connected to the power supply, control system and actuator.

2) Parameter setting: According to the production requirements, set the appropriate guiding parameters in the control system, such as the guiding speed, tension, etc.

3) Simulation test: Under the condition of no load or simulated load, start the correction system for preliminary test to observe its response speed and correction accuracy.

4) Actual operation test: connect the trainer to the production line for actual operation test to check its stability and reliability in continuous working state.

5) Adjustment and optimization: According to the test results, the parameters of the deviation correction system are adjusted and optimized as necessary to ensure that it reaches the best working state.

There are a few things to note about the safety precautions of the automatic trainer:

1) Do not open the case when the power is on, and do not turn on the power after opening the shell, otherwise there is a risk of electric shock.

2) Do not disassemble or modify this equipment, otherwise fire, malfunction and misoperation may occur.

3) The automatic deviation correction system needs to be grounded, otherwise it may lead to electric shock.

4) This device does not have explosion-proof function, so it is not suitable for installation where explosion-proof function is required.

5) Do not place in places with high temperature, high humidity, dusty and corrosive gases to avoid vibration and impact. Otherwise, electric shock, fire, and breakdowns are prone to occur.

6) Conductive substances such as metal sheets or combustible foreign substances such as engine oil should not enter the inside of the rectifier, otherwise it will cause fire, damage and malfunction of the equipment.