Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

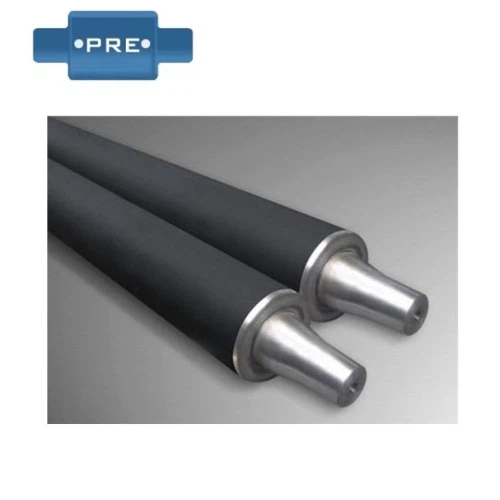

Aluminum guide rolls, also known as aluminum alloy guide rollers, are made through the selection of high-quality aluminum alloy materials (6063-T5) through molds

Tubular type (from the outer diameter of 30mm~220mm) of various specifications, aluminum guide wheel with stiffener structure, high strength. And the use of precision equipment and special tools for surface finishing, so that the surface is smooth, the coaxiality reaches 0.02mm, the whole axis is corrected by computer balance within 2g, the shaft end of the special process and with imported bearings, in high-speed operation, can run easily. According to the different needs of the industry, its surface can also be specially treated: sandblasting, anilox, Teflon and special hardening treatment HV700, aluminum guide wheels make it have good scratch resistance and wear resistance.

How to ensure that the aluminum roller achieves a high degree of dimensional accuracy, surface quality and mechanical properties through strict technological innovation and meets the demand for good quality aluminum roller in printing, plastic film, metal rolling and other industries, mainly has the following technical points:

1) Raw material selection and pretreatment: Aluminum alloy materials with high purity and less impurities are selected as the base materials, and the quality of raw materials is ensured by strict chemical composition analysis and mechanical property testing. The pretreatment consists of homogenizing annealing to remove internal stresses and provide a good metallographic basis for subsequent processing.

2) High-precision forging and rolling: Precision forging technology is used to form a preliminary shape, and then through multi-pass cold and hot rolling, the deformation and processing temperature are accurately controlled, the grain is gradually refined, the density and uniformity of the material are improved, and the foundation is laid for obtaining high-precision size and surface finish.

3) Precision cutting and grinding: CNC machine tools are used for precision cutting, and the final size and shape are accurately matched according to strict tolerance requirements. This is followed by fine grinding, including cylindrical grinding, internal bore grinding and surface grinding, to ensure a surface roughness of less than Ra0.1 μm to meet the needs of the application.

4) Heat treatment strengthening: According to the requirements of the use of aluminum rollers, the implementation of customized heat treatment processes, such as solution treatment plus aging, to improve hardness, strength and wear resistance, while ensuring the necessary toughness, to avoid cracks or deformation in use.

5) Surface treatment and coating: In order to resist corrosion and reduce friction of aluminum rollers, surface treatment technologies such as electroplating, anodizing or spraying Teflon are adopted. Special applications also require abrasion-resistant and anti-stick coatings to adapt to different working environments and increase service life.

The surface treatment methods of aluminum rollers are mainly as follows:

1. General white oxide surface: moderate surface hardness HV300, low cost, different color surfaces (such as pure black) can also be provided according to customer requirements, suitable for low tension film industry.

2. Brown hard oxide surface: high surface hardness HV700 and oxide film thickness above 0.1mm, oxidation technology introduced in Taiwan, high hardness and high wear resistance can be applied to a variety of high tension and thick materials, which can greatly improve the service life of aluminum rollers.

3. Teflon Surface: A special Teflon coating makes the ink easy to clean and provides moderate anti-sticking.

4. Rubber surface: With aluminum roller as the mandrel, different rubber layers can provide versatility with different characteristics and different hardness.

5. Industrial hard chrome surface: surface hardness and corrosion resistance, surface roughness can be as low as Ra0.01 (super-mirror), compared with traditional chrome-plated steel rollers, lightweight chrome-plated aluminum rollers can be applied to higher speed machines.

6) Precision testing and quality control: The whole production process implements strict online testing and finished product inspection, and uses high-precision testing equipment such as coordinate measuring instrument and surface roughness meter to ensure that each link meets the requirements of high standards and finally produces good quality aluminum rollers with good performance.

To sum up, through comprehensive measures such as precise material selection, processing technology, heat treatment and surface treatment, combined with a modern quality management system, we can ensure the production of good quality aluminum rollers that meet the high standards of various industries, and promote the quality and technological progress of related manufacturing industries.

Aluminum guide rollers play an important role in modern industry and are widely used in many fields such as packaging, printing, papermaking, textiles and electronics. Its light weight, corrosion resistance, high thermal conductivity, and good mechanical strength make it ideal for many industrial applications. The specific key role of aluminum guide rollers in modern industry is mainly as follows:

1) In the packaging industry, aluminum guide rollers are widely used for the transfer and handling of film and paper. They are able to provide a uniform surface and a smooth coating, ensuring the quality and appearance of the packaging material. The high thermal conductivity of the aluminium guide rollers enables fast and uniform heat transfer during the heat sealing process, increasing production efficiency and reducing energy consumption.

2) In the printing industry, aluminum guide rollers are an indispensable component. Good quality aluminum guide rollers can ensure the clarity and consistency of the printed pattern and improve the quality of the printed matter. Surface treatment techniques such as anodizing and chrome plating for aluminium guide rollers further improve their wear and corrosion resistance, extend service life and reduce maintenance costs.

3) In the paper industry, aluminum guide rollers also play an important role. They are used in processes such as calendering, coating and drying of paper to ensure its flatness and gloss. The lightweight nature of the aluminium guide rollers also makes the operation of the equipment more flexible and fast, improving the overall efficiency of the production line.

4) The application of aluminum guide rollers in the textile industry cannot be ignored. They are used in processes such as flattening, shaping, and coating fabrics to ensure the flatness and quality of fabrics. The high thermal conductivity of aluminum guide rollers is particularly important in the heat setting process, as it can transfer heat quickly and evenly, improve production efficiency and ensure product quality.

5) In the electronics industry, aluminum guide rollers are used to manufacture various films and circuit boards, and their high precision and stability ensure the quality and consistency of the products. The corrosion resistance of aluminum guide rollers also makes them excellent when handling chemicals, extending the life of the equipment and reducing the frequency of maintenance.

Previous: The Key Papermaking Equipment - Guide Rollers

Next: How Do Aluminum Guide Rollers Meet Different Machining Needs?