Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

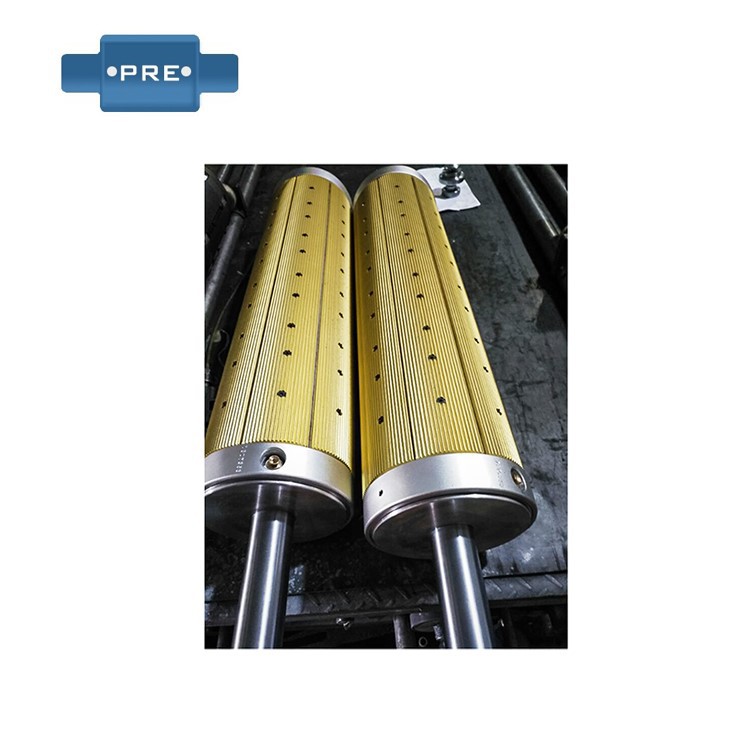

As an efficient and convenient rewinding and unwinding tool, the expanded pneumatic shaft plays an important role in many fields, and needs to be comprehensively considered according to the actual needs and working environment when purchasing and using.

The inflatable shaft is extremely convenient and fast to use, and when in use, you only need to bring your own air source to control the air pressure in the range of 6-8kg/cm². When it is necessary to lock the external parts (such as a round paper tube), simply inflate the air valve on the air shaft with the air gun to resist the external parts, and when it is necessary to loosen the paper discharge, the external parts can be easily removed by simply pressing the slider on the air valve with your hand.

So, do you know what are the capacity and main advantages of inflatable bearings?

1. Affordability

The bearing capacity of the inflatable shaft is mainly reflected in its load-bearing weight and the range of pressure it can withstand.

The weight capacity of an inflatable bearing varies depending on the specific design and application, but in general, an inflatable shaft has a good load-bearing capacity, especially in a specific design scenario. The inflatable shaft is a shaft that protrudes the surface by high-pressure inflation, this design allows it to withstand large radial loads, and in the inflated state, the surface of the inflatable shaft can closely fit the drum material, providing stable support and positioning, thus ensuring that the drum material will not slide or offset during high-speed rotation or conveying. The load-bearing capacity of an inflatable shaft is also related to its material and structure, generally speaking, the shell of an inflatable shaft is made of metal materials, such as stainless steel or aluminum alloy, which have high strength and rigidity and are able to withstand greater torsional and compressive stresses. The internal structure of the inflatable shaft, such as telescopic elements, guide sleeves and sealing devices, has also been carefully designed to ensure that it can maintain stable performance and long service life during use. The load-bearing capacity of an inflatable shaft is not infinite, it is limited by a variety of factors such as material strength, structural design and inflation pressure, therefore, when selecting an inflatable shaft, it is necessary to determine whether its load-bearing capacity meets the needs according to the specific application scenarios and requirements. In short, the inflatable shaft has a good load-bearing capacity, but the specific load-bearing capacity needs to be determined according to the actual application.

1) Large bearing weight:

The load-bearing capacity of the inflatable shaft can be adjusted to a certain extent. According to the actual needs of customers, the size of the shaft diameter can be determined, and materials such as high-hard steel can be used to increase its bearing weight. For example, if the weight is more than 1 ton, an inflatable shaft made of steel can be used.

In practical applications, the inflatable shaft is able to stably carry coils or materials of various weights, ensuring a smooth production process.

2) Wide range of adaptable pressure:

The inflatable shaft is locked by high-pressure inflation, and its internal structure and material are designed to withstand a certain range of air pressure.

During the inflation process, the inflatable shaft is able to respond quickly and achieve the desired locking effect, while maintaining the stability and safety of the structure.

2. Key Benefits:

1) Short inflating operation time:

The separation and placement of the shaft from the paper core or other material takes a very short time, such as 3 seconds or less, to complete the inflation and deflation process.

This efficient inflation allows the inflatable shaft to quickly switch between coils or materials during the production process, increasing production efficiency.

2) Paper core placement is simple:

By inflating and deflating the action, it is easy to move and fix the paper core or other material at any position on the shaft surface.

This flexibility allows the shaft to be used in a wide range of production environments.

3) Cost-effective:

The design of the inflatable shaft is designed for the actual work needs, and it can be applied to various types of coils such as thickness, thinness, width and narrowness.

In the process of use, the inflatable shaft can reduce manual operation time and material waste, and reduce production costs.

4) Long service time and simple maintenance:

As a mechanical component, the inflatable shaft has a fixed specification and interchangeability for each part in its construction, making repair and maintenance easy and convenient.

At the same time, the service life of the inflatable shaft is long, which can reduce the frequency and cost of replacing parts.

5) Wide range of applications:

All slitting, printing, rewinding, coating, laminating, bag-making, papermaking and other process equipment or other related center winding machinery can be applied to the inflatable shaft.

As an independently designed part, the inflatable shaft is available in a variety of specifications from 1 inch to 12 inches, and the length and size are determined by the actual needs of the customer.

The application field of the inflatable shaft is very wide, covering almost all the mechanical equipment that requires the function of winding and unwinding.

Here are some of the main application areas:

Printing industry: On the printing machine, the inflatable shaft is used to fix the paper roll or printing material to ensure the flatness and stability of the material during the printing process.

Textile industry: In textile machinery, the inflatable shaft is used to stretch fabrics, fix fabrics, etc., and its flexible inflation and deflation functions allow fabrics to be easily coiled or released on the shaft, thus adapting to different production needs.

Coating industry: On the coating machine, the inflatable shaft is used to fix the coating material to ensure the smooth progress of the coating process, and by accurately controlling the inflation volume of the inflatable shaft, the uniform coating of the coating material can be realized, and the coating effect and product quality can be improved.

Other industries: In addition to the above industries, inflatable shafts are also widely used in slitting machines, die-cutting machines, rewinding machines, paper tube machines, bag making machines, laminating machines, laminating machines and other mechanical equipment, in which inflatable shafts play an important role in fixing and releasing coils.

Previous: What Are The Main Factors That Affect The Load-bearing Capacity Of The Air Expanded Shaft

Next: How To Install An Air Shaft Correctly And Safely On The Machine