Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

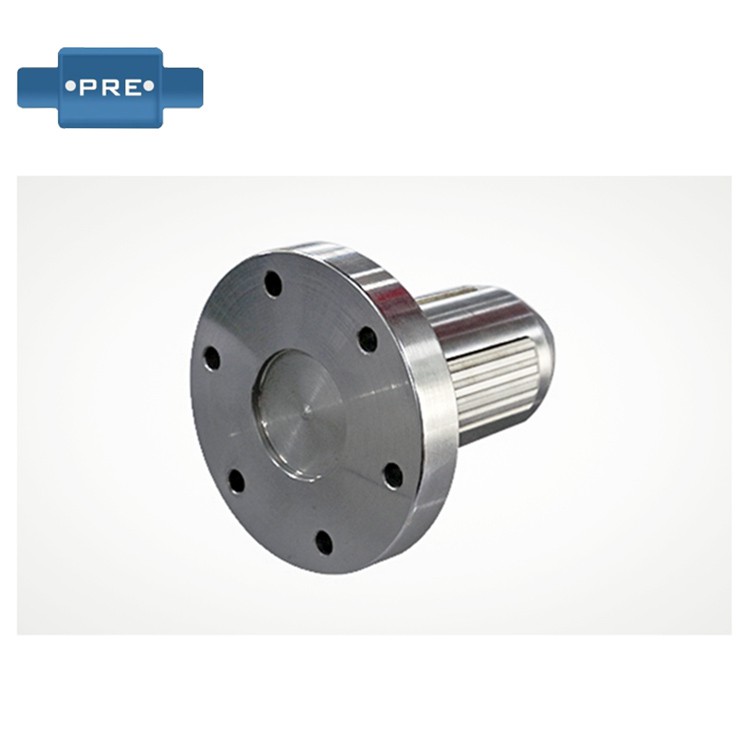

The mechanical chuck is used in the shaftless rewinding and unwinding mechanical structure. The movable devices on both sides of the machine are used to fix the core of the chuck for rewinding and unwinding. Advantages of mechanical chuck: mechanical chucks do not need complex pipelines and pneumatic hydraulic systems, chucks do not need lubrication, and low maintenance costs; The contact area with the barrel is large, which will not break the paper core, saving costs. The parts of the chuck wear are less and the chuck has a long service life. Prevents slippage and makes tension control more reliable. The chucks can be quickly changed to meet the needs of different working conditions, and the double-joint chucks can be quickly replaced with various specifications of chucks to be suitable for various sizes of barrels, saving costs, among which the commonly used are 3 inches, 4 inches and 6 inches and other specifications. The flange and mandrel of the chuck are integral forging structure, with high strength and good load-bearing, which avoids the situation that the flange and mandrel of the chuck break off due to fatigue stress caused by long-term load-bearing.

Mechanical chucks are generally divided into rotary mechanical chucks and side-push mechanical chucks, which are the core components of industrial winding and unwinding systems, and each has unique advantages in structural design, application scenarios and performance. In the PRE factory, there are two main series of side-push mechanical chucks: NEB and AED. The rotary mechanical chucks mainly include AEB series.

The working principle of the side-thrust mechanical chuck: when the chuck is subjected to lateral thrust, the key bar expands outward and compresses the coiled tube. When the thrust is released, the keyway automatically returns.

This mechanical chuck is the most suitable chuck for hydraulic paper holders, and when the hydraulic arm moves and pushes sideways, the fan structure expands and fixes and automatically aligns.

The working principle of the rotary mechanical chuck: the front face of the chuck is rotated at a certain angle by the action of the rotating torque, and the key bar expands outward and compresses the coiled tube. When the rotation torque is released, the key bar automatically returns. Widely used in various machines for coiling and unwinding, this type of mechanical chuck uses a simple sliding principle to expand the fan structure to fix the barrel and automatically align it, this chuck makes the barrel can be reused many times to reduce the loss of the barrel.

Pushing Mechanical Core Chuck

Structural design: Based on the wedge-slide mechanism, the axial thrust is converted into radial expansion force. And the clamping force automatically increases with the load. Some models support the "Fallback Adjustment" function, which uses a butterfly spring and connecting shaft to optimize the fit of the slide to the inner wall of the core and improve the clamping stability.

Merit:

1) Pure mechanical strengthening, good anti-slip performance

The axial thrust is converted into radial expansion by the wedge-slide mechanism, and the clamping force is automatically increased with the load, so that there is no risk of loosening, even in high-torque conditions such as titanium coil slitting.

The patented structure (such as the retraction adjustment design) makes the slider fully fit and contact with the inner wall of the core, and improves the torque transmission efficiency by more than 30%.

2) Anti-bending moment and anti-vibration design

Heavy-duty bearings support toothed positioning springs that resist 4620N·m bending moments under long overhangs (e.g., 9.84 inches) to avoid loss of accuracy caused by bending deformation.

3) Adaptability of precision work

The combination of nickel-plated hardened bayonet and imported bearing, runout tolerance ≤ 0.01mm, suitable for high-precision scenarios such as printing registration and optical film cutting.

Rotary mechanical chuck

Structural design: The cam mechanism is used to drive the expansion key strip to achieve radial expansion. The common "3" to 6" integrated design allows for core format changeover without the need to change parts. Purely mechanical transmission, relying on the rotational force of the equipment to drive the expansion mechanism, no pneumatic/hydraulic system.

Merit:

1) Integrated design, efficient switching

The 3'' VS 6'' rotary mechanical chuck is a combination of 3" and 6" that allows for quick and easy switching between different core sizes (e.g., paper cores, film cores) without the need to change parts, significantly reducing downtime and increasing line flexibility.

2) Load-bearing and damage-resistant capabilities

The cam mechanism drives the expansion key strip to provide a large contact area to avoid breaking the paper core (especially thin-walled rolls), about the maximum bearing capacity, the 3-inch bearing capacity is 1500kg/PCS, and the 6-inch bearing capacity is 4000kg/PCS, so the bearing capacity of the rotary mechanical chuck is relatively strong, suitable for heavy-duty coil processing.

Less wear parts, lubrication-free for life, and reduced maintenance costs.

3) Strong environmental adaptability

The structure itself is a pure mechanical structure, without the installation of pneumatic/hydraulic systems, and can operate stably in dust-free workshops, high temperature or corrosive environments (such as lithium battery coating lines, food packaging).

4) Outstanding dynamic stability

The expansion key strip is designed to prevent "jamming", and the high concentricity reduces vibration to ensure the tension control accuracy at high speed winding (such as 250m/min of slitting machine).

Contact factory in Guangdong, China

(Over 20 years experience in core chucks production )

Previous: Mechanical Chucks And Air Pneumatic Shafts, How To Choose

Next: What Is The Difference Between A Mechanical Chuck And A Safety Chuck?