Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Rolls are common components in industrial production machines, and in the paper industry, rolls are mainly involved in paper molding, supporting, transferring, pressing, drying, winding and so on. Today, we try to stand in the purchaser and technician's point of view to understand the paper machine commonly used rollers, understand their functions, can better maintenance or purchase.

In the paper industry, rollers are mainly used for transfer, pressing, coating, calendering, cooling, slitting and other processes to ensure paper quality, thickness uniformity, surface finish and production efficiency. The papermaking process is as follows:

1) After the raw pulp comes out of the headbox, it is evenly spread on the netting, which is driven by the breast rolls and volute rolls propped up.

2) Press section, including several pairs of press rolls up and down extrusion dehydration;

3) drying section, by dozens of drying cylinders, guide rollers can be adjusted to adjust the size of the blanket wrap angle to adjust the drying cylinders and the contact area of the wet paper sheet; and then to the sizing rollers, generally a pair of the back of the general have to install a few pairs of drying cylinders for drying dewatering;

4) calendering roller, the last procedure, the upper and lower surface calendering can be rolled after the paper, rolled into the desired finished paper.

Different roles of the rollers have different names, specifically categorized as follows:

1) ambidextrous rollers

- Function: Located in the wet sheet molding area (e.g., long web section), there is a wiper (before the water line) and a vacuum suction box (after the water line) under the web, which is collectively known as the web section. Vacuum suction or mechanical pressure helps dewater fibers and form a uniform paper web.

- Characteristics: Surface opening design, combined with vacuum system to realize efficient dewatering.

2) Press rolls: Flat rolls are used for both normal and positive presses. The structure of the flat roll press is that the upper roll is a stone roll and the lower roll is a rubber roll, and both rolls have a flat and smooth surface.

- Function: Further dewatering by mechanical pressure in the pressing section, reducing energy consumption for subsequent drying.

- Classification is as follows:

a. Stone rolls: Stone rolls are usually made of materials that are easy to peel off from the paper, mostly granite. The main feature of granite is that there are many tiny pores in its organization, storing a certain amount of air, which is conducive to the peeling of wet paper sheets, the disadvantage is the high cost and easy to brittle. In operation, such as too fast speed or load may produce overheating of the shaft head, so that the surface of the stone roller axial or annular cracks, high-temperature expansion of the seriousness of the shaft will cause the shaft to fall off.

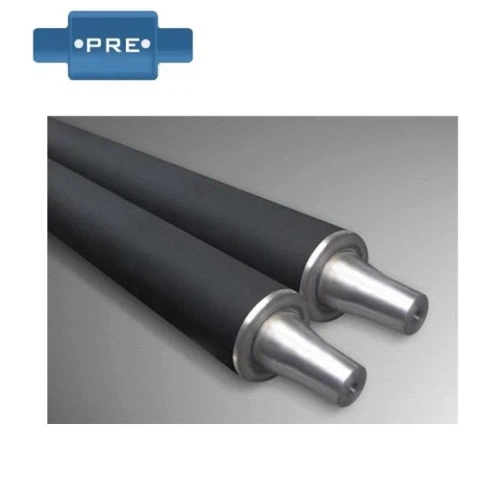

b. Rubber rollers: not only to provide corrosion resistance of the rollers, but more importantly, to provide good flexibility to ease the upper pressure roller on the wet paper pressure, thus reducing the wet paper "pressurization". The elasticity of the rubber-covered lower roll also provides good contact between the two rolls, even dewatering, and compensates for high errors in the lower roll. The rubber hardness of the rolls in the production of normal paper is usually 70 to 90 Shore hardness.

- Post-maintenance: paper machine press rolls in the operation process due to material flushing, often in the transmission parts of the wear problem, such as the press roll bearing bit wear and so on. Traditional repair methods include surfacing, thermal spraying, electroplating, etc.

(3) drying rolls: the dryer mainly consists of a number of drying rolls, each with a hot air circulation system between the rolls, to ensure that the paper can dry quickly and evenly. The drying section of the paper machine and its drying roll design and material selection on the efficiency of the papermaking process and paper quality has a decisive impact.

- Function: In the drying section through the steam heating evaporation of paper moisture, usually arranged in multiple sets of drying cylinders.

- Structure: Drying rolls are usually made of high quality metal materials, such as cast iron or stainless steel; steam is passed inside; the surface is coated with a special alloy or ceramic layer to improve its durability and corrosion resistance, and the surface is smooth for even heat transfer.

(4) Calendering rolls: When the paper enters the calender after initial molding from the paper machine, it will first pass between several calendering rolls. In the operation process, the pressure adjustment system plays a key role. The pressure between the calendering rolls is precisely adjusted by means of hydraulic or mechanical screws, etc., so that the paper is squeezed uniformly and steadily as it passes between the rolls.

- Function: Improve paper smoothness, gloss and thickness uniformity by high temperature and pressure in calender.

- Material: High hardness alloy or composite material with high hardness and good abrasion resistance, partly equipped with controllable medium-high technology.

- Paper calendering has important significance in paper production:

a. Improve the quality of paper: through calendering, it can eliminate the unevenness and roughness of the paper surface, make the paper smoother and improve the quality of paper.

Make the paper smoother, improve the texture and feel of the paper.

b. Improve the printing effect: paper surface smoothness can improve the fineness and accuracy of the printing

degree, so that the printing effect is more clear and vivid.

c. Increase the gloss of paper: calendering can improve the optical properties of paper, so that the light of paper

d. Increase the glossiness of paper: calendering can improve the optical properties of paper, make the paper glossier, and increase the visual effect of paper.

e. Enhance the mechanical strength of paper: calendering can increase the density and strength of paper, enhance the abrasion and folding resistance of paper.

The calendering can increase the density and strength of the paper, improve the abrasion resistance and folding resistance of the paper, and prolong the service life of the paper.

f. Improve the transparency of the paper: calendering can reduce the scattering and reflection of the paper surface, improve the transparency and light transmission of the paper.

(5) Guide rolls and tension rolls

Guide roll: the structure of the paper machine guide roll The paper machine guide roll is mainly composed of roll body, bearings, seals and other parts. Roll body is the main part of the guide roll, usually made of steel, the surface after special treatment, with high wear resistance and corrosion resistance. Bearing is the core part of the guide roller, it bears the gravity of the roller body and the pressure generated by the movement of paper to ensure the normal operation of the guide roller. Seals are mainly used to prevent the friction between the paper and the roll body leading to paper breakage, but also play a role in dustproof and waterproof.

- The role of the guide roller and tension roller: to guide the running path of the paper web, to adjust the tension, to avoid wrinkles or breaks.

Contact factory in Guangdong, China

(Over 20 years experience in rollers production )