Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

Tel: +86-134-31394972

E-mail: sales@pre-webguidesystem.com

The pneumatic core expanding shaft is powered by high-pressure gas, and the shaft with a convex surface is controlled by inflation and deflation to achieve the surface expansion and tightness control of the shaft.

According to the structural classification of the inflatable shaft: it can generally be divided into slat-type inflatable shaft, key-type inflatable shaft and through-bar inflatable shaft.

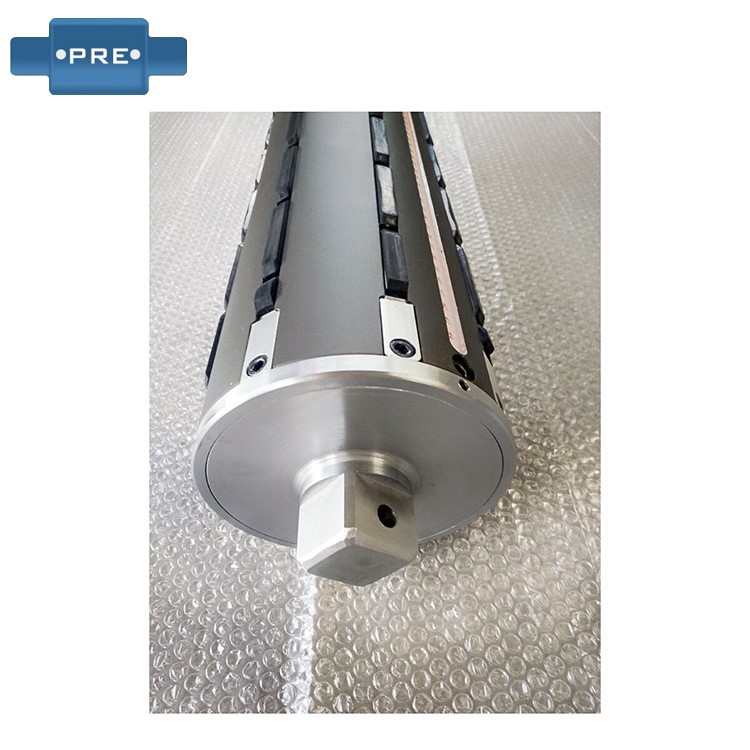

The expansion part of the lug type expanable shaft is the keybar, which is usually evenly distributed on the circumference of the shaft, and the shaft body is generally made of excellent steel pipe, and the surface is treated with hard chrome plating to improve wear resistance and corrosion resistance; The key bar is mostly made of aluminum alloy or stainless steel, etc., which has good strength and rigidity. It is suitable for winding materials with high loads and high torques.

The expansion part of the leaf type core shaft is a plate, the shaft body is usually made of steel or aluminum, which is used for load-bearing, the plate material is mostly aluminum alloy, the number of plates of the plate type inflatable shaft is generally 6 or more, and there is a certain gap between the plates, so that it can expand evenly when inflated. It is suitable for machinery with high winding precision or lighter items.

Multi bladder type air expanding shaft is through-length, that is, it is continuously distributed along the length of the shaft, rather than spaced distribution like the key-type inflatable shaft, which makes the force of the key bar more uniform and the run-out tolerance accuracy is higher when the inflatable shaft is working. It is suitable for occasions with high requirements for precision and load-bearing, such as some high-end printing and packaging equipment.

According to the material classification of the inflatable shaft: the structure of the inflatable shaft includes the shaft body, the internal expansion body and the expansion part composed of special synthetic rubber. There are three types of materials that are usually used for the shaft body, namely steel, aluminum, and stainless steel. Tile type inflatable shaft and key type inflatable shaft, these three materials may be used, and the through-length key inflatable shaft is more steel than stainless steel, and the through-length key inflatable shaft is generally more made of No. 45 steel, because the through-length key is a solid shaft, and the material of stainless steel is relatively hard, so the machine generally cannot be processed. In general, it is according to our material load to choose which material is needed, such as the lighter load-bearing load is aluminum, the heavier load is steel, if you are worried about rust and the load-bearing is heavier, it will be better to choose stainless steel.

The selection of material also needs to look at the style of the air expansion shaft, like the general tile type is aluminum, the shaft head will be made of steel, and the tube of the shaft body is selected according to the load. The same goes for the keybar type. The through-length key type cannot process stainless steel, and generally more is made of No. 45 steel, because the through-length key is a solid shaft, and the material of stainless steel is relatively hard, so the machine generally cannot be processed.

The following important elements are generally required when customizing an inflatable shaft:

(1) Diameter specifications: the common diameter is 3 inches (76mm), 6 inches (152mm), etc., because the inflatable shaft is matched with the size of the inner hole of the reel, so the inner diameter size of the barrel needs to be measured, if there is an old inflatable shaft, it is good to directly measure the size of the old inflatable shaft.

(2) Length range: customized according to the width of the equipment, which can range from tens of centimeters to several meters. The length can be subdivided into shaft head length and shaft body length.

(3) Maximum load-bearing: The maximum load-bearing weight of the inflatable shaft is related to the material, structure and air pressure of the shaft body (usually the air pressure range is 0.4-0.8MPa). When customizing an inflatable shaft, if you are not sure what material to use to make the inflatable shaft, you generally need to provide the maximum load-bearing weight to the inflatable shaft supplier, and then the inflatable shaft manufacturer will recommend the appropriate material based on the data, generally using aluminum and steel materials more.

The most important factors: In fact, it will be clearer to mark the above important factors in the sketch. If it is not convenient to draw drawings, PRE, the manufacturer of inflatable shafts, can also help draw drawings according to the provided elements, and can modify them until the final drawings are completely correct before starting production.

The use of inflatable shaft is very wide, and all machines with winding, unwinding and slitting can be applied to inflatable shafts, even including light metal industries. For example, the inflatable shaft is mainly suitable for printing equipment: drying machine, flexo printing machine, gravure machine, trademark printing machine, rewinding machine, paper tube machine, bag making machine, laminating machine, laminating machine, film blowing machine, foaming machine, laminating machine, embossing machine, paper machine, non-woven machine and so on.

Contact factory in Guangdong, China

(Over 20 years experience in air shafts production )