At present, as plastic films are more and more widely used in life, the plastic film manufacturing industry is also developing rapidly. Existing plastic films are usually manufactured using film blowing machines.

Blown film machine is a special equipment to blow plastic particles into film after heating and melting. Blown film machine through the extruder will melt plastic through the head filter by the heated die head extrusion, cooled by the internal and external cold air ring blowing into film bubble, and then through the bubble stabilising frame, herringbone plate, traction rollers and crimping device to collect this plastic film.

Restricted by the parallelism between the different rollers and the installation precision between the components and other issues, the film winding process is prone to runout, resulting in the phenomenon of uneven levels when winding, thus affecting the normal winding of the film.

However, due to the great elasticity of plastic film, if the offset between the rollers will have a great impact on the film winding, the current electronic measurement of film offset equipment is very accurate, but the response of the mechanical equipment takes some time, the response time is very slow compared to the deformation of the film, so there is a need for a fast response, and high accuracy of the corrective device to correct the offset of plastic film, and also the need for a high accuracy of the plastic film winding process, and also the need for the plastic film winding process. It is also necessary to provide an emergency response in case of large-scale deviation of the plastic film.

- Meaning of deskew system: The technical operation of producing rolls in the process of spraying, printing, punching, laminating, slitting, or other roll winding processes, always keeping the sides of the rolls neat and consistent. Its wide use has brought great benefits to the industry, and the deskew control has made the automation of the industries such as iron and steel, corrugated paper, textile, printing, labels, sticking labels, papermaking, plastic films, construction materials, cables, rubber, tyres, non-woven fabrics, and so on. Corrugated paper processing and other industries appear automated control.

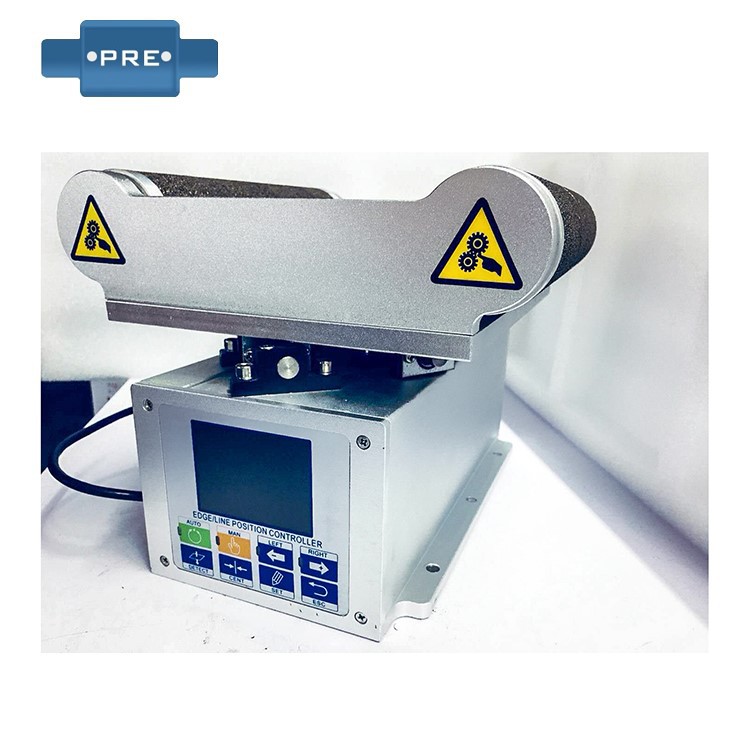

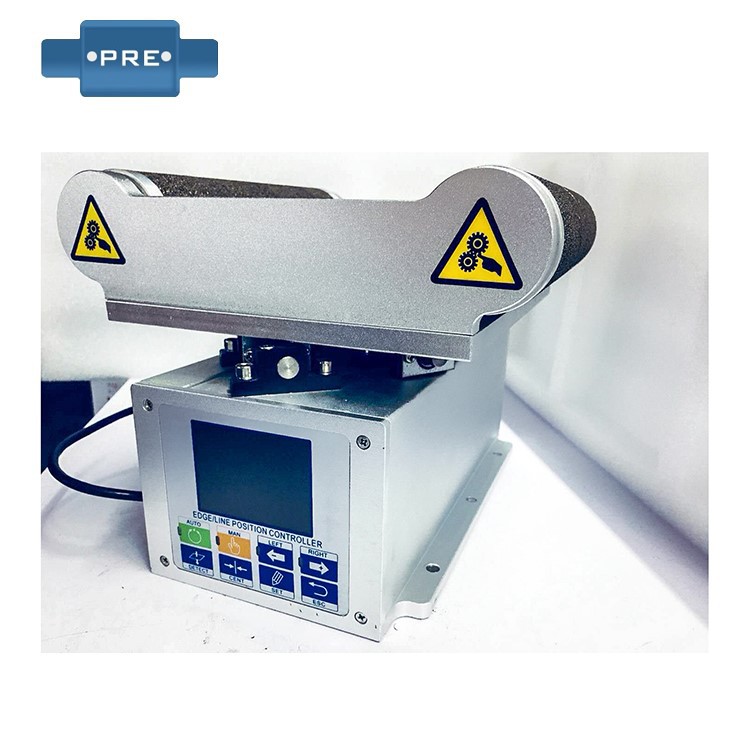

- Principle of deskewing system: Infrared light/ultrasonic wave/laser/visible light is sent from deskewing sensor B to monitor the running of the web and send the signal to controller A. The controller finds that the web has drifted in position. When the controller finds that the web has drifted, it controls the swinging of the guiding frame C through the driver D to correct the web position according to the pre-set instructions of the controller.

signals to the controller, which, after being judged and processed by the control unit, controls the drive motors and corrects the web in the deviated position to the correct position.The FIFE deviation correction system offers several different detection methods: edge detection, line following or centring. The drive system is driven by low-speed synchronous, frequency-controlled, stepper and servo motors, and the drive stroke is strictly proportional to the web offset.The system can also be used with different probes to suit the needs of detecting different coils, such as: infrared photoelectric, analogue infrared photoelectric. The microcomputer digital controller provides precise control of all system functions. The automatic web guiding system uses photoelectric sensors to detect the edge position of the web and sends the measured position error.

- The mode selection of the web guiding system: depends on the degree of material processing. Unprocessed materials can only be guided according to the centre line of the material's edges, as there are no other comparative characteristics for these materials to refer to. Processed materials have additional characteristics for deskew, such as printed lines or contrasting edges. To enable analogue or digital deskew sensors to scan the position of the material. The left and right edges of the material are corrected using edge guiding sensors. According to the centre line of the material, two edge guiding sensors are used for guiding.

Contact now